PET Sheet Extrusion Line: Meeting the Demands of the Food Packaging Industry

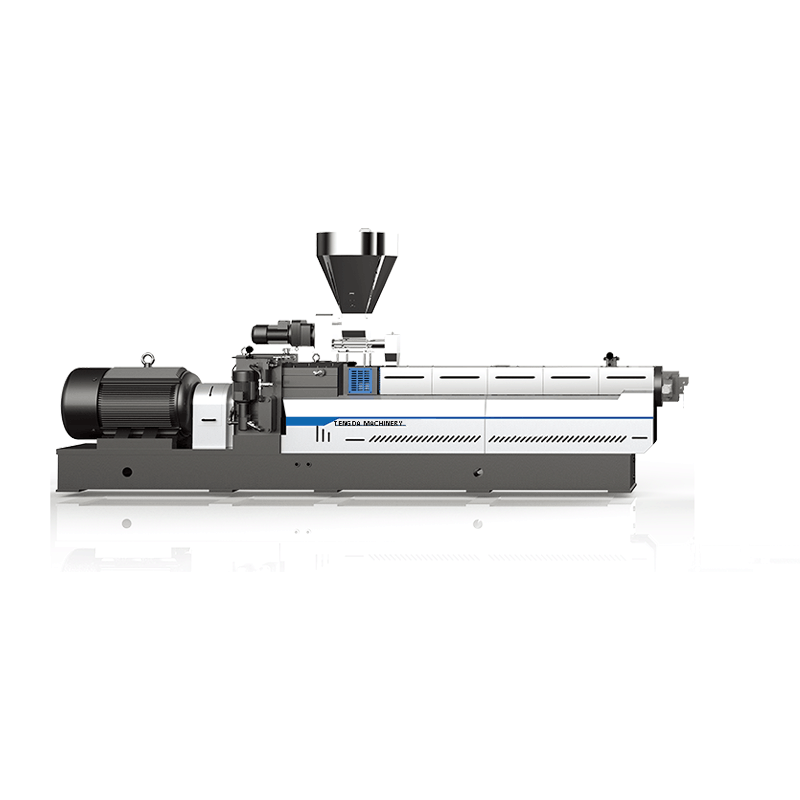

The food packaging industry is constantly evolving and innovating to meet the demands of consumers and maintain the integrity and freshness of food products. To ensure efficient and high-quality packaging solutions, manufacturers rely on advanced technology and equipment. One such technology that has revolutionized food packaging is the PET (Polyethylene Terephthalate) sheet extrusion line. This article explores the features and benefits of PET sheet extrusion lines and how they are meeting the specific demands of the food packaging industry.

Sustaining Food Safety with PET Sheet Extrusion Lines

The safety of food products is of utmost importance, and packaging plays a critical role in preserving food quality and preventing contamination. PET sheet extrusion lines offer a range of features that make them ideal for food packaging applications.

PET is a widely used packaging material due to its excellent barrier properties, strength, and transparency. PET sheets are resistant to water, grease, and chemicals, ensuring the hygiene and safety of packaged food. The extrusion process enables manufacturers to produce sheets of varying thicknesses, allowing them to tailor the packaging to the specific requirements of different food products.

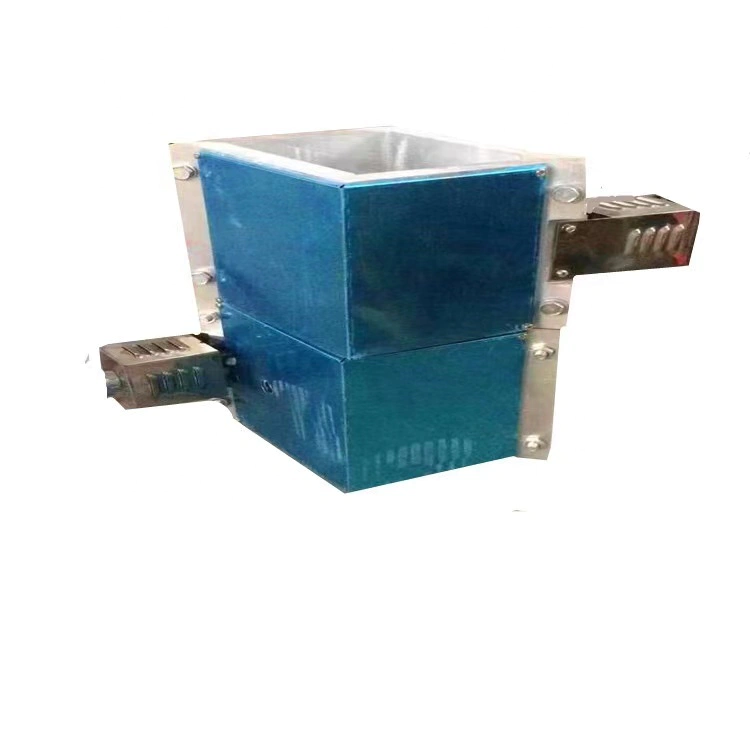

Moreover, PET sheet extrusion lines incorporate advanced technology to ensure the cleanliness and purity of the packaging. The lines are equipped with systems that remove dust, impurities, and any residual materials from the sheets, guaranteeing the highest levels of sanitation. This is crucial for the food industry, where strict regulatory standards must be met to protect consumer health.

Enhancing Efficiency and Productivity

In addition to ensuring food safety, PET sheet extrusion lines offer enhanced efficiency and productivity to meet the growing demands of the food packaging industry.

These extrusion lines are designed for high-speed production, allowing manufacturers to meet tight deadlines and large order quantities. The automated nature of these lines reduces manual labor, minimizing the chances of human error and increasing overall productivity.

Furthermore, PET sheet extrusion lines incorporate intelligent control systems that optimize energy usage and minimize waste. These systems monitor and adjust various parameters such as temperature, speed, and thickness to achieve the desired quality while minimizing resource consumption. By reducing energy and material waste, manufacturers can improve their sustainability and reduce production costs.

Flexibility and Customization

The food industry is diverse, with an array of products ranging from delicate confectioneries to sturdy canned goods. To cater to these different packaging requirements, PET sheet extrusion lines offer flexibility and customization options.

Manufacturers can choose from a wide range of PET sheet thicknesses and sizes to suit the specific needs of their products. Thicker sheets provide added protection and durability for products such as meat and seafood, while thinner sheets are preferred for items like chocolates and pastries. This versatility allows food manufacturers to select the most appropriate packaging materials that ensure product integrity and consumer satisfaction.

Additionally, PET sheet extrusion lines enable the integration of various additives and coatings into the sheets. These additives can enhance the properties of the packaging, such as UV protection, anti-fogging, or anti-static properties. By customizing the sheets with specific additives, manufacturers can extend the shelf life of food products, maintain their visual appeal, and meet unique storage and transportation requirements.

Eco-Friendly Packaging Solutions

As the world becomes increasingly conscious of environmental issues, sustainable packaging solutions are gaining traction. PET sheet extrusion lines contribute to eco-friendly packaging practices in several ways.

Firstly, PET is a fully recyclable material, meaning that it can be processed and reused to produce new packaging products. PET sheet extrusion lines can utilize recycled PET resin, reducing the demand for virgin materials and minimizing the carbon footprint of the packaging industry.

Furthermore, the energy-efficient features of PET sheet extrusion lines significantly reduce energy consumption compared to traditional manufacturing methods. The intelligent control systems optimize energy usage and minimize waste, aligning with sustainable manufacturing practices.

In Summary

PET sheet extrusion lines are revolutionizing the food packaging industry by meeting its unique demands for safety, efficiency, customization, and sustainability. The advanced technology incorporated into these lines ensures the hygiene and purity of the packaging while enhancing productivity and reducing waste. The flexibility and customization options provided by PET sheet extrusion lines enable food manufacturers to select packaging materials that suit their specific requirements. Moreover, these lines contribute to eco-friendly practices by utilizing recyclable materials and minimizing energy consumption.

With the ever-evolving needs of the food packaging industry, PET sheet extrusion lines are at the forefront of delivering innovative and reliable packaging solutions. As consumers continue to prioritize food safety, sustainability, and customization, PET sheet extrusion lines are likely to play an even more significant role in shaping the future of food packaging.

In the present growing world of emerging technology, the has demanding operation in various sectors like plastic extruder machine manufacturers, extruder machine manufacturers, plastic extruder machine manufacturers and many other industries at extruder machine manufacturers levels of manufacturing and designing.

Now you can enjoy plastic extruder machine manufacturers with Nanjing Tengda Machinery Co., Ltd.'s latest collection of extruder machine manufacturers Application products. Do visit now, at TENGDA Extruder Machine Manufacturers.

People are more likely to listen to an expert than just anyone off the street. So, while pack mentality is important, having a relevant expert speak to the effectiveness of a brand's product as TENGDA is essential to converting new consumers as well.