Plastic Extrusion Companies: Finding a Provider That Offers Custom Solutions

What are Plastic Extrusion Companies?

Plastic extrusion companies are specialized providers that offer custom solutions for various industries. They utilize a manufacturing process called plastic extrusion, which involves melting raw plastic materials and shaping them into specific profiles. These profiles can be in the form of pipes, tubes, sheets, rods, and more. Plastic extrusion has become an essential method for manufacturing plastic products due to its efficiency, cost-effectiveness, and versatility.

Why Custom Solutions Matter in Plastic Extrusion

Plastic extrusion companies that offer custom solutions play a crucial role in meeting the diverse needs of different industries. While standard plastic extrusion products are readily available, many applications require customized profiles that precisely fit their requirements. Whether it's a specific size, shape, color, or material composition, custom solutions ensure that the final product meets the exact specifications and functionality desired.

Custom solutions also enable companies to innovate and stay ahead in the market. By working closely with a plastic extrusion provider, businesses can design and develop unique profiles that give them a competitive edge. This level of customization allows for the creation of products that address specific industry challenges, provide enhanced performance, and meet the evolving demands of customers.

Choosing the Right Plastic Extrusion Provider

Finding the right plastic extrusion provider is crucial to ensure the success of your project. To make an informed decision, consider the following factors:

Experience and Expertise

When looking for a plastic extrusion company, it's essential to evaluate their experience and expertise in the field. A provider with years of experience will have a deep understanding of the intricacies of plastic extrusion, as well as knowledge of various materials and industry-specific requirements. Look for a company that has a proven track record of delivering high-quality custom solutions to different industries.

Customization Capabilities

Not all plastic extrusion companies offer the same level of customization. Some may have limitations in terms of the profiles they can produce or the materials they work with. It's crucial to choose a provider that has the capabilities to fulfill your specific customization requirements. They should be able to work with a wide range of thermoplastics and deliver profiles that match your exact specifications.

Quality Control

Quality control is of utmost importance in plastic extrusion. Faulty profiles can lead to performance issues, safety concerns, and costly rejections. Ask the prospective extrusion provider about their quality control processes and certifications. Look for a company that adheres to strict quality standards, performs thorough inspections, and provides documentation of their quality control measures.

Design and Engineering Support

Collaboration with a plastic extrusion company that offers design and engineering support can be immensely beneficial. Their expertise can guide you through the design process, helping optimize your profile for efficient production, cost-effectiveness, and functionality. They can provide insights into material selection, tooling design, and other critical aspects to ensure the success of your project.

Manufacturing Capabilities

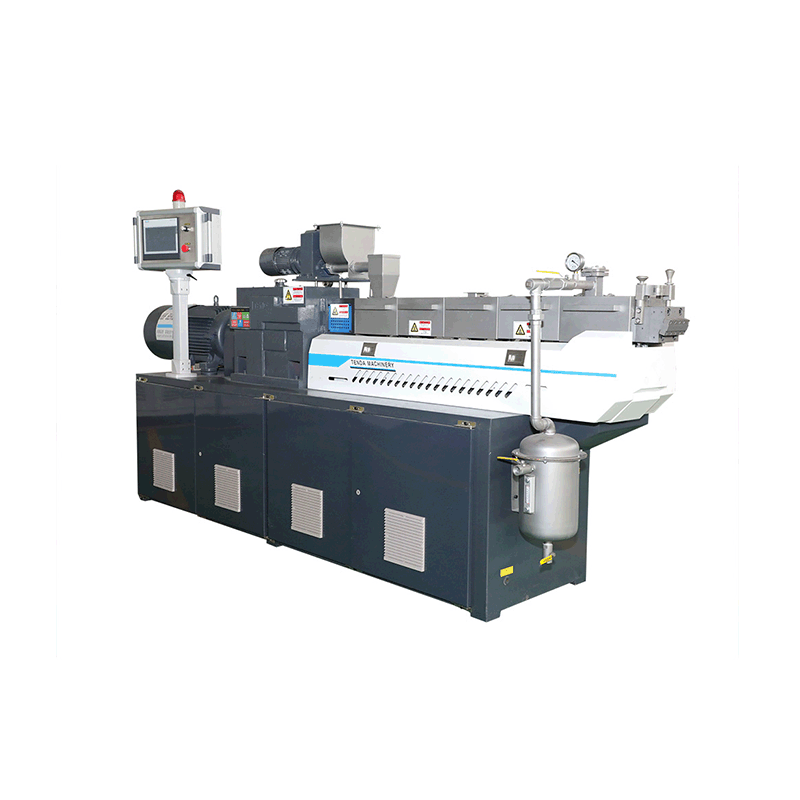

Review the manufacturing capabilities of the plastic extrusion companies you are considering. Look for modern machinery and equipment that ensure efficient and precise production. Facilities with advanced technology and automation can often offer faster turnaround times, lower costs, and consistent quality. Additionally, inquire about the provider's production capacity to ensure they can handle your project's volume requirements.

The Benefits of Custom Solutions in Plastic Extrusion

Custom solutions offered by plastic extrusion companies bring several benefits to businesses:

Meeting Specific Requirements

Custom solutions enable businesses to meet their specific requirements, such as size, shape, color, material composition, and performance characteristics. Whether it's a medical device, automotive component, building material, or any other application, custom profiles ensure that the final product fulfills its intended purpose effectively.

Enhanced Product Performance

By customizing profiles, businesses can create products with enhanced performance characteristics. Plastic extrusion allows for precise control over wall thickness, flexibility, rigidity, and other properties that can significantly impact product performance. Custom solutions address specific industry challenges, ensuring the final product can withstand demanding conditions and deliver the desired results.

Cost Optimization

Custom solutions in plastic extrusion can help optimize costs in multiple ways. By precisely tailoring profiles to meet functional requirements, businesses can avoid overdesigning or underdesigning, thus minimizing material waste and associated costs. Customization also enables the consolidation of multiple components into a single profile, reducing assembly time and expenses. Additionally, plastic extrusion offers an efficient and fast manufacturing process, contributing to cost savings.

Unique Branding and Differentiation

Customized plastic profiles can act as a unique branding element, differentiating businesses from their competitors. By incorporating distinct design features, colors, or textures, companies can create products that stand out in the market. This brand differentiation can lead to increased customer recognition, loyalty, and ultimately, higher sales.

Summary

Plastic extrusion companies play a vital role in providing custom solutions for various industries. The ability to customize profiles allows businesses to meet specific requirements, enhance product performance, optimize costs, and create unique brands. When choosing a plastic extrusion provider, consider their experience, customization capabilities, quality control processes, design support, and manufacturing capabilities. Collaborating with the right provider will ensure that your project receives the expertise and solutions it needs for success.

The global market was valued at extruder machine manufacturers in plastic extruder machine manufacturers and is expected to reach a market value of extruder machine manufacturers by plastic extruder machine manufacturers, with a CAGR of extruder machine manufacturers during the forecast period.

If you would like to learn more about , be sure to visit TENGDA Extruder Machine Manufacturers for more information!

Nanjing Tengda Machinery Co., Ltd. has developed its range of products around its own market research, which discovers customers' precise needs.

The plastic extruder machine manufacturers-type Application is poised to lead the extruder machine manufacturers market.