Plastic Extrusion Companies: The Advantages of Customizing Your Manufacturing Process

The Advantages of Customizing Your Manufacturing Process

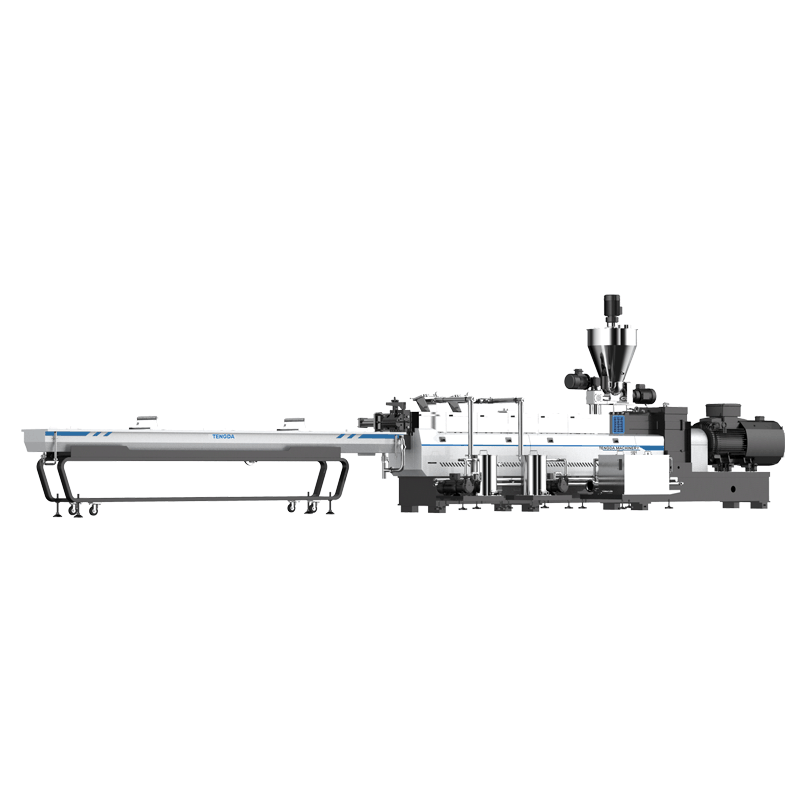

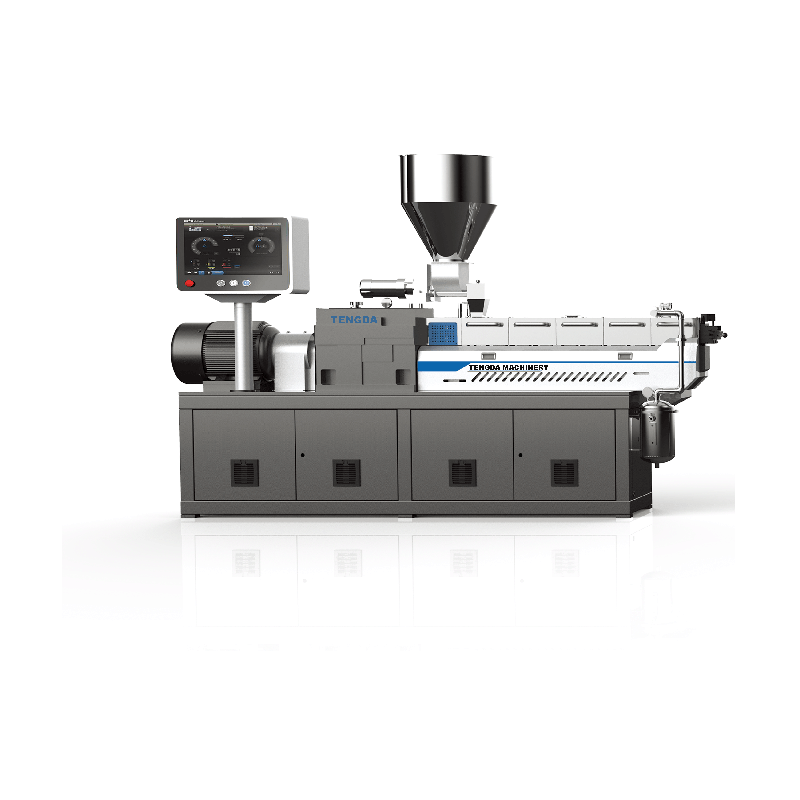

In the world of plastic extrusion, customization is key to meet the diverse needs and demands of different industries. Plastic extrusion companies, equipped with state-of-the-art technology and expertise, play a vital role in transforming raw materials into customizable plastic profiles, tubes, and sheets. This article explores the significant advantages of customizing your manufacturing process, highlighting the unique opportunities it brings to businesses across various sectors.

The Power of Customization

Customization is the process of tailoring products or services to meet specific requirements. When it comes to plastic extrusion, customization allows companies to create highly specialized plastic products that cater to unique design, functionality, and performance specifications. By customizing their manufacturing process, companies can gain a competitive edge in the market by offering innovative solutions that precisely meet the needs of their target audience.

Enhanced Product Performance and Functionality

One of the primary advantages of customizing the plastic extrusion manufacturing process is the ability to enhance product performance and functionality. By working closely with a plastic extrusion company, businesses can create profiles or components that are specifically designed to meet the desired performance characteristics. This allows for the production of plastic products that offer superior strength, durability, flexibility, and thermal resistance, ensuring they can withstand even the most demanding applications.

Customized plastic extrusions can also incorporate additional features and functionalities depending on the requirements. For example, companies can integrate color pigments, UV stabilizers, flame retardants, or any other additives to enhance the overall properties of the plastic. Furthermore, manufacturers can develop precision profiles with intricate shapes, sizes, textures, and finishes, enabling seamless integration into assemblies or products.

Improved Cost-efficiency and Material Utilization

Contrary to what some may believe, customizing the manufacturing process in plastic extrusion can lead to significant cost savings in the long run. When products are tailored to specific requirements, it eliminates the need for excess materials, resulting in improved material utilization. This eliminates waste and reduces costs associated with the raw materials.

Additionally, customized plastic extrusions can contribute to cost reduction by eliminating the need for secondary operations or assembly. Integrating multiple features or functionalities into a single extrusion eliminates the additional costs of combining various components through assembly processes. This streamlines production, increases efficiency, and reduces overall production costs.

Fast Turnaround Times and Shorter Lead Times

By investing in customized plastic extrusion, businesses can benefit from faster turnaround times and shorter lead times compared to standard manufacturing processes. When products are customized, it eliminates the need for additional modifications, adjustments, or refinements, as the extrusion is developed to meet the precise requirements right from the start. This significantly reduces the time required to bring a product to market and speeds up the overall production process.

Furthermore, plastic extrusion companies often have the capacity and expertise to handle high-volume orders efficiently. With their advanced production capabilities, they can fulfill large-scale orders within tight deadlines, ensuring businesses can meet their customer demands promptly. This not only improves customer satisfaction but also helps businesses maintain a competitive advantage in the market.

Design Flexibility and Innovation

Customization in plastic extrusion allows businesses to have complete design flexibility and lends itself to innovation. With the assistance of experienced engineers and designers, companies can explore new possibilities in product design, pushing the boundaries of what can be achieved with plastic extrusions.

By collaborating with a plastic extrusion company, businesses can benefit from their expertise in understanding material properties, design limitations, and manufacturability. This collaboration fosters innovation by creating products that were previously thought to be impossible or impractical. The design flexibility in plastic extrusion enables the production of unique shapes, sizes, and geometries that can contribute to the differentiation of products in the market.

Conclusion

Customization in the plastic extrusion manufacturing process brings numerous advantages to businesses operating in a wide range of industries. From enhanced product performance and functionality to improved cost-efficiency and faster lead times, customization allows businesses to stay ahead of the competition. Moreover, design flexibility and innovation fostered by customization enable businesses to create unique, cutting-edge solutions that cater to the ever-changing needs of their customers.

In an era where personalization and tailored solutions are highly valued, plastic extrusion companies play a vital role in helping businesses meet the demands of their target audience. By embracing customization, businesses can unlock a world of possibilities, ensuring their products stand out in a competitive market landscape. So, if businesses want to achieve optimal results and meet the diverse needs of their customers, customization in the plastic extrusion manufacturing process is a strategic choice that should not be overlooked.