Plastic Extrusion Companies: The Importance of Working with an Experienced Provider

Introduction

Plastic extrusion is a widely used manufacturing process in various industries, including automotive, construction, packaging, and more. It involves melting plastic resin and forcing it through a die to create a specific shape or profile. To ensure high-quality and precise extrusions, it is crucial to work with experienced plastic extrusion companies. Partnering with an experienced provider brings numerous benefits, such as technical expertise, advanced equipment, quality assurance, and cost efficiency. In this article, we will explore the importance of working with an experienced plastic extrusion company and how it can significantly impact your business.

Technical Expertise: Driven by Experience

One of the primary advantages of collaborating with an experienced plastic extrusion company is the technical expertise they bring to the table. Years of experience in the field equips these companies with an in-depth understanding of the extrusion process, materials, and potential challenges that may arise during production. They know how to tackle complex projects, overcome obstacles, and deliver exceptional results.

Experienced plastic extrusion companies have a team of skilled engineers and technicians who are well-versed in the intricacies of the process. They can provide valuable insights and suggestions during the design phase, ensuring that your product is optimized for efficient extrusion. Their expertise allows them to identify potential design flaws, choose the most appropriate materials, and recommend improvements that can enhance the overall performance of your extruded plastic components.

Advanced Equipment: Precision and Versatility

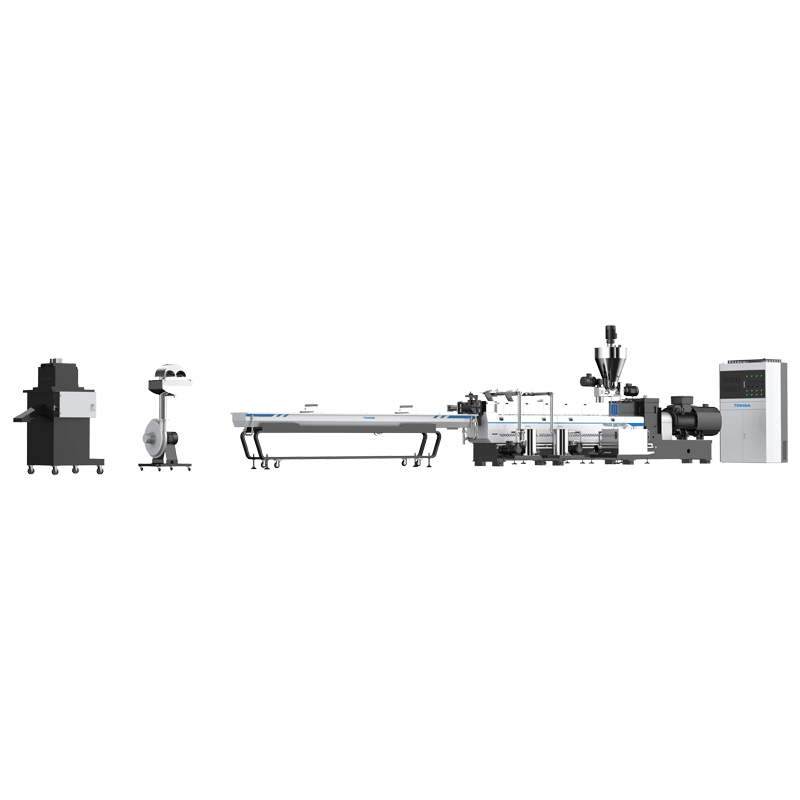

Another significant advantage of working with an experienced provider is access to advanced extrusion equipment. These companies continuously invest in state-of-the-art machinery, which enables them to achieve a higher level of precision, consistency, and versatility in their extrusion processes. Cutting-edge equipment ensures that the extrusions meet tight tolerances and adhere to specific design requirements.

Advanced extrusion machinery also allows experienced providers to offer a wide range of extruded shapes, sizes, and profiles. Whether you require simple tubes, complex profiles with intricate detailing, or custom-designed extrusions, an experienced plastic extrusion company can deliver. With their advanced equipment, they have the capability to produce extrusions in various materials, including PVC, ABS, HDPE, and more.

Quality Assurance: Consistency and Reliability

Maintaining consistent quality is of utmost importance in any manufacturing process, and plastic extrusion is no exception. An experienced plastic extrusion company understands the significance of quality control and has robust systems in place to ensure that every extruded component meets the highest standards.

Experienced providers employ quality assurance techniques throughout the entire production process. They carefully monitor the extrusion parameters, such as temperature, speed, and pressure, to guarantee consistency in the final products. They also perform regular inspections and tests, both during and after extrusion, to verify dimensional accuracy, surface finish, and structural integrity.

By working with an experienced provider, you eliminate the risk of subpar extrusions that could compromise the functionality or safety of your product. Experienced companies have a reputation for delivering reliable, high-quality extrusions consistently, making them a trustworthy partner for your plastic extrusion needs.

Cost Efficiency: Saving Time and Resources

Contrary to what some may believe, collaborating with an experienced plastic extrusion company can lead to significant cost savings in the long run. While the initial cost may be slightly higher than some less experienced providers, the value they bring to the table far outweighs the price difference.

Experienced providers can streamline the extrusion process, optimizing material usage, reducing waste, and minimizing production time. Their technical expertise allows them to identify potential bottlenecks and implement efficient solutions that can improve productivity and reduce overall costs.

Moreover, relying on an experienced provider eliminates the need for costly trial and error periods. Their knowledge and understanding of the extrusion process enable them to get it right the first time, reducing the risk of errors or design flaws that could result in expensive reworks or product recalls.

Additionally, working with an experienced plastic extrusion company means access to a vast network of suppliers and industry contacts. These connections often result in better pricing agreements for raw materials and other essential components, further contributing to cost savings for your business.

Summary

Partnering with an experienced plastic extrusion company brings numerous benefits to your business. Their technical expertise, advanced equipment, and commitment to quality assurance ensure that you receive high-quality extruded components that meet your exact specifications. By working with an experienced provider, you can save time, resources, and costs in the long run, ultimately enhancing your overall competitiveness in the market.

So, when considering plastic extrusion companies for your next project, be sure to prioritize experience and choose a trusted partner who can deliver outstanding results. Invest in the expertise and knowledge that an experienced plastic extrusion company brings to the table, and watch your ideas come to life through precise and efficient extrusions.