Plastic Recycling Extruder: How It Works and Its Advantages

Introduction:

Plastic waste has become a pressing environmental issue, posing a great threat to our planet. In recent years, recycling initiatives have gained momentum as an effective solution to mitigate this crisis. Among the various recycling methods, the plastic recycling extruder stands out as an innovative and efficient technology. This article will delve into the working mechanism and advantages of the plastic recycling extruder, shedding light on its crucial role in sustainable waste management.

The Basics of Plastic Recycling Extruder:

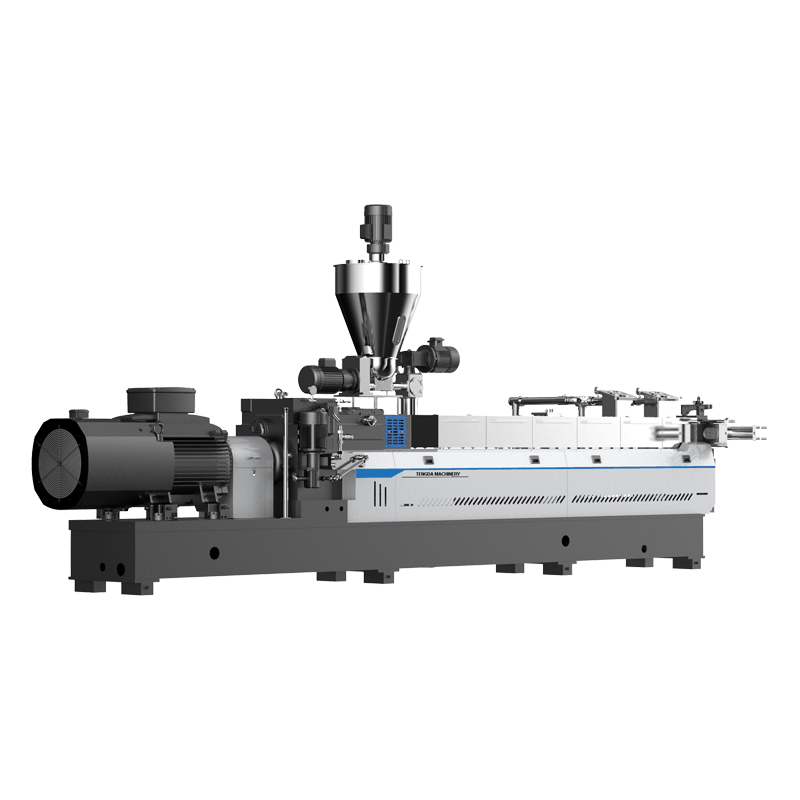

Plastic recycling extruders are cutting-edge machines designed to convert plastic waste into usable materials. By utilizing heat and pressure, these extruders can melt down different types of plastic, including polyethylene, polypropylene, and polystyrene. The melted plastic is then transformed into durable raw materials, which can be further processed and used in various industries.

One of the key components of the plastic recycling extruder is the extrusion screw. This spiral-shaped screw is responsible for effectively mixing and melting the plastic feedstock. As the plastic enters the extruder through a hopper, it goes through a heating zone where it is exposed to high temperatures. The extrusion screw continuously rotates, exerting mechanical energy that assists in breaking down the plastic molecules. This combination of heat and mechanical force allows the plastic to soften and attain a molten state.

Once the plastic reaches the molten stage, it passes through a die, which imparts the desired shape and size to the material. The extruded plastic is then cooled using either air or water, solidifying it into a workable form. The final product can be in the form of plastic pellets or filaments, depending on its intended application.

Advantages of Plastic Recycling Extruder:

Sustainable Waste Management:

Plastic recycling extruders play a crucial role in sustainable waste management. By repurposing plastic waste, these machines reduce the amount of plastic that ends up in landfills or oceans. This not only helps to alleviate the environmental burden but also conserves valuable resources. Additionally, utilizing recycled plastic reduces the demand for virgin materials, leading to decreased energy consumption and greenhouse gas emissions associated with their production.

Economical Solution:

Another remarkable advantage of plastic recycling extruders is their economic viability. Plastic waste is often considered a liability, but with these machines, it can be turned into a valuable asset. By transforming waste into usable raw materials, businesses can save on procurement costs and reduce their reliance on expensive virgin plastics. Moreover, the market demand for recycled plastic is growing steadily, creating opportunities for businesses to generate revenue from their recycling efforts.

Wide Range of Applications:

Plastic recycling extruders produce high-quality recycled plastic materials that can be utilized in a wide array of applications. The versatility of these materials allows them to replace virgin plastics in various industries, including packaging, construction, automotive, and electronics. Recycled plastic can be molded, extruded, and even 3D printed, offering endless possibilities for manufacturers and designers.

Environmental Benefits:

In addition to reducing reliance on virgin plastics, plastic recycling extruders are instrumental in decreasing energy consumption and carbon emissions. Manufacturing products from recycled plastic requires significantly less energy compared to producing them from raw materials. Furthermore, the extraction and processing of raw materials for virgin plastics contribute to environmental degradation, including deforestation and pollution. By opting for recycled plastics, companies can contribute to a circular economy and help protect our natural resources.

Job Creation:

The implementation of plastic recycling extruders not only benefits the environment but also contributes to job creation and economic growth. The recycling industry has the potential to generate employment opportunities at various stages, from collection and sorting to operating and maintaining recycling equipment. These jobs span different skill levels, bringing economic benefits to communities and supporting local economies.

Conclusion:

The plastic recycling extruder is a revolutionary technology that offers numerous advantages in tackling the plastic waste crisis. By repurposing plastic waste and transforming it into valuable raw materials, these machines promote sustainable waste management, reduce environmental impact, and contribute to economic growth. As the demand for recycled plastics continues to rise, it is essential to embrace and invest in this transformative technology. Together, we can make a significant difference in preserving our planet for future generations.

To live up to our responsibilities to serve and enhance the communities in which Nanjing Tengda Machinery Co., Ltd. works and lives and the society on which we depend.

Nanjing Tengda Machinery Co., Ltd. is proud to be recognized as some of the most important and influential providers for global customers.Visit us at TENGDA Extruder Machine Manufacturers.

Nanjing Tengda Machinery Co., Ltd. really created a whole persona around Application’s manufacturing and selling, and it's so innovative that people really respond to it.

Nanjing Tengda Machinery Co., Ltd., which prides itself on Application for applying in different ways.