Plastic Recycling Extruder: Revolutionizing the Recycling Industry

Introduction:

The recycling industry plays a crucial role in reducing waste and promoting sustainability. With the ever-increasing amount of plastic waste generated globally, finding effective solutions for plastic recycling has become more important than ever. One such groundbreaking innovation that is revolutionizing the recycling industry is the plastic recycling extruder. This advanced technology has the potential to change the way we recycle plastics, offering numerous benefits such as increased efficiency, reduced costs, and improved environmental impact. In this article, we will delve into the details of the plastic recycling extruder and explore its impact on the recycling industry.

The Need for Advanced Recycling Technologies

Plastic recycling has long been an integral part of waste management systems worldwide. However, traditional recycling processes often face limitations and challenges. Conventional methods involve sorting, shredding, and re-melting the plastic to create new products. While this approach has been effective to some extent, it is often time-consuming, energy-intensive, and limited in terms of the types of plastic it can process.

The Advancements in Plastic Recycling Extruders

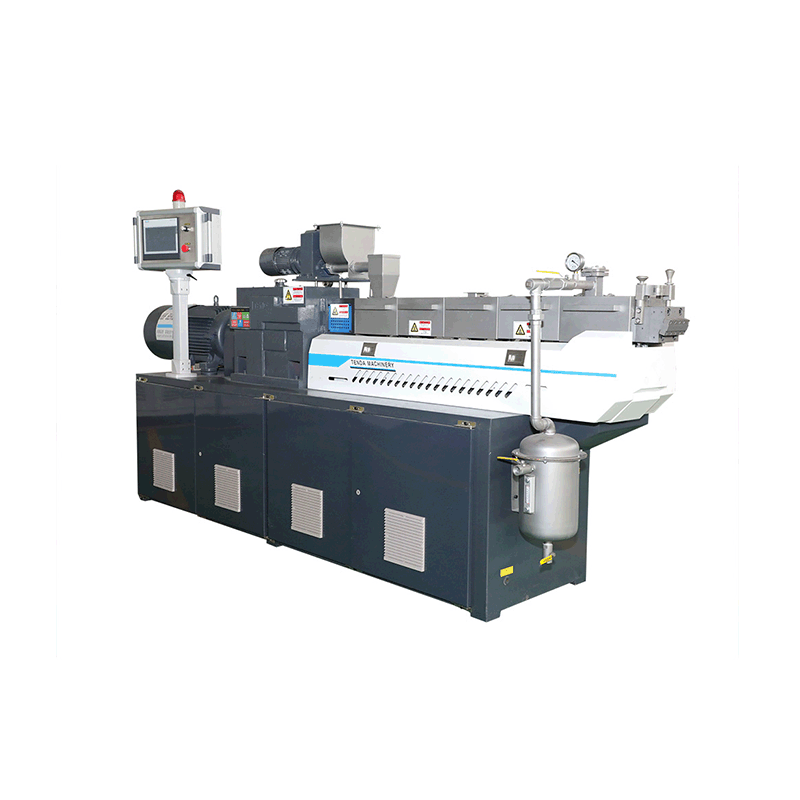

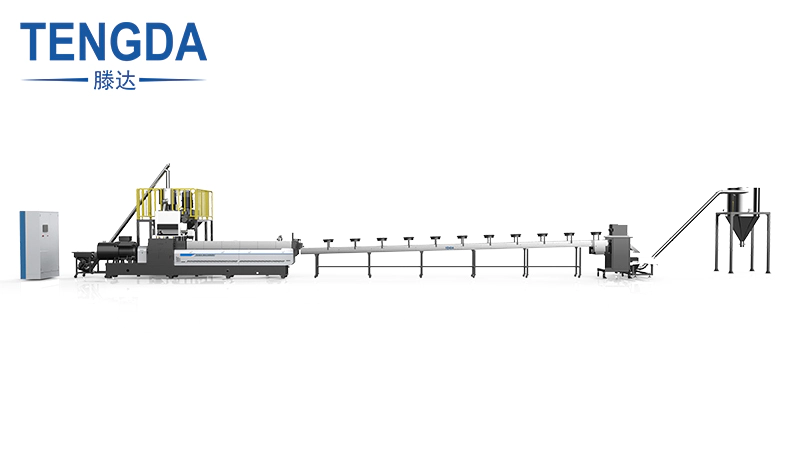

A plastic recycling extruder is a cutting-edge technology that offers a more efficient and versatile approach to plastic recycling. This advanced machine combines the processes of shredding, melting, and extrusion into a single continuous operation. By doing so, it eliminates the need for multiple machines and significantly reduces the time and energy required for recycling.

The extruder works by feeding plastic waste into a hopper, where it is crushed, shredded, and melted simultaneously. The molten plastic is then forced through a die, which gives it a specific shape or form. This process can be customized to produce various types of plastic products, including sheets, filaments, pellets, and even 3D printing materials.

Moreover, plastic recycling extruders are designed to handle different types of plastic, including commonly used polymers such as polyethylene (PE), polypropylene (PP), and polystyrene (PS). This versatility enables the recycling of a wide range of plastic waste, including packaging materials, containers, and even discarded products.

The Benefits of Plastic Recycling Extruders

The introduction of plastic recycling extruders has brought about significant advantages for the recycling industry. Let's explore some of the key benefits:

1. Enhanced Efficiency: Traditional recycling methods often involve multiple steps, leading to downtime, increased labor costs, and energy consumption. Plastic recycling extruders streamline the process by integrating shredding, melting, and extrusion into a single continuous operation. This not only saves time and labor but also increases overall efficiency.

2. Reduced Costs: By eliminating the need for multiple machines and simplifying the process, plastic recycling extruders offer cost-effective solutions for recycling plastic waste. The reduced energy consumption and labor requirements also contribute to lower operational costs.

3. Expanded Recycling Potential: The versatility of plastic recycling extruders allows for the processing of a wide range of plastic waste. This opens doors to recycling various types of plastics and products that were previously challenging or economically unviable to recycle.

4. High-Quality Output: Plastic recycling extruders ensure the production of high-quality recycled plastic products. The continuous operation and controlled extrusion process result in consistent and uniform materials, suitable for a wide range of applications.

5. Environmental Impact: Perhaps one of the most significant advantages of plastic recycling extruders is their positive impact on the environment. By diverting plastic waste from landfills and reducing the need for virgin plastics, these machines contribute to the conservation of resources, energy savings, and reduced greenhouse gas emissions.

Applications of Plastic Recycling Extruders

Plastic recycling extruders have found numerous applications across various industries due to their versatility and high-quality output. Some of the notable applications include:

1. Manufacturing: The recycled plastic materials produced by extruders can be used in manufacturing processes to create a wide range of products. From furniture and construction materials to automotive components and consumer goods, the applications are vast.

2. 3D Printing: As 3D printing continues to gain popularity, the demand for high-quality printing materials is also on the rise. Plastic recycling extruders can produce filaments specifically designed for 3D printing, offering sustainable alternatives to traditional plastic filaments.

3. Packaging: Plastic packaging is a significant source of waste globally. Plastic recycling extruders can convert plastic waste into sheets, films, or pellets suitable for manufacturing packaging materials, reducing the reliance on virgin plastics.

4. Construction: The construction industry is increasingly incorporating recycled plastics in various applications. Plastic recycling extruders can produce materials such as plastic lumber, paving tiles, and insulation panels, offering sustainable alternatives to traditional construction materials.

5. Textiles: Recycled plastic materials from extruders can also be transformed into fibers suitable for textile production. These fibers can be used in the manufacturing of clothing, upholstery, carpets, and other textile-based products.

Conclusion:

The plastic recycling extruder is undoubtedly revolutionizing the recycling industry by offering a more efficient, cost-effective, and environmentally sustainable solution for plastic waste. With its ability to process a wide range of plastics and produce high-quality recycled materials, this advanced technology holds immense potential for a greener future. By adopting and investing in plastic recycling extruders, we can significantly reduce plastic waste, conserve resources, and move towards a circular economy where plastic products are endlessly recycled. It is imperative for industries, governments, and individuals to embrace this revolutionary technology and make it an integral part of our sustainable waste management systems. Let us work together to create a cleaner and greener world for generations to come.

Nowadays, the adoption of Application in extruder machine manufacturers industry is quite common.

If you need Application solution, you should always consult a professional provider. Nanjing Tengda Machinery Co., Ltd. is one such a competent provider that is highly qualified to offer a wide range of products and services. Visit today!

Nanjing Tengda Machinery Co., Ltd., which prides itself on Application for applying in different ways.

Rewards and discount programs give customers more reason to come back for Application again, especially in the competitive retail and services markets.

Nanjing Tengda Machinery Co., Ltd. deems Application as evolutionary rather than revolutionary. We've always had these 'social commerce' marketplaces in some form.