Plastic Recycling Extruder: The Benefits of Investing in High-Quality Equipment

The Benefits of Investing in High-Quality Equipment for Plastic Recycling Extruder

Plastic waste has become a major global concern due to its detrimental impact on the environment. As the demand for plastic products continues to grow, so does the need for effective and sustainable recycling solutions. Plastic recycling extruders have gained significant attention in recent years as a reliable and efficient method to process and recycle plastic waste. Investing in high-quality equipment for plastic recycling extruders offers numerous benefits, ranging from reducing environmental pollution to economic advantages. In this article, we will delve into the advantages of investing in high-quality equipment for plastic recycling extruders, emphasizing their role in mitigating plastic waste and fostering a sustainable circular economy.

Enhanced Efficiency and Productivity

Investing in high-quality equipment for plastic recycling extruders brings forth improved efficiency and productivity. High-quality extruders are designed to operate seamlessly, ensuring a smoother and more continuous recycling process. This leads to higher throughput, reducing downtime and increasing overall productivity. With the ability to process large quantities of plastic waste, high-quality extruders significantly contribute to meeting the recycling demands of the plastic industry.

Moreover, high-quality extruders are equipped with advanced technologies that enhance their operational efficiency. Innovative features such as automated feeding systems, precision temperature control, and real-time monitoring mechanisms optimize the recycling process, resulting in faster turnaround times and higher-quality recycled plastic output.

Superior Quality Output

One of the key advantages of investing in high-quality equipment for plastic recycling extruders is the production of superior quality recycled plastic. High-quality extruders are designed to process a wide range of plastic waste, enabling the production of recycled plastic pellets or granules with consistent quality and desirable properties. These extruders are capable of efficiently melting, filtering, and homogenizing plastic waste, ensuring that the final recycled plastic output meets strict quality standards.

With high-quality equipment, the recycled plastic undergoes thorough cleaning, removing impurities, contaminants, and undesirable additives. This enhances the overall purity and quality of the recycled plastic, making it suitable for a multitude of applications in various industries. The superior quality of the output not only increases its value in the market but also reduces the reliance on virgin plastic production, further promoting sustainability.

Reduced Environmental Impact

Investing in high-quality equipment for plastic recycling extruders plays a crucial role in reducing the environmental impact of plastic waste. By recycling plastic waste, the need for raw materials derived from fossil fuels is significantly reduced. This, in turn, results in a substantial decrease in energy consumption and greenhouse gas emissions associated with the production of virgin plastic.

Moreover, high-quality extruders enable the recycling of a wider range of plastic waste, including post-consumer and post-industrial plastics. This helps divert plastic waste from landfills, eliminating the risk of pollution and the release of harmful chemicals into the environment. By investing in high-quality equipment, businesses and organizations can actively contribute to a cleaner and healthier environment.

Cost Savings and Economic Benefits

Investing in high-quality equipment for plastic recycling extruders can yield substantial cost savings and economic benefits in the long run. While the initial investment may seem significant, the efficiency and productivity of high-quality extruders contribute to reduced operational costs over time. The higher throughput, reduced downtime, and lower maintenance requirements result in increased overall profitability.

Additionally, the production of high-quality recycled plastic with consistent properties opens up new market opportunities and revenue streams. The demand for recycled plastic is on the rise, driven by the need for sustainable materials in various industries. By investing in high-quality equipment that produces superior-grade recycled plastic, businesses can cater to this growing demand and establish a strong position in the market.

Promotion of Circular Economy

Investing in high-quality equipment for plastic recycling extruders aligns with the principles of a circular economy. The circular economy model aims to minimize waste generation, promote recycling, and reintroduce materials into the production cycle. By recycling plastic waste using high-quality extruders, businesses actively participate in closing the loop and reducing the reliance on virgin plastic.

Furthermore, the recycled plastic output from high-quality extruders can be utilized in a wide range of applications, from packaging materials to construction products. By supporting the use of recycled plastic, businesses contribute to the sustainable development and conservation of natural resources. This promotes a circular economy where materials are recycled and reused, reducing the strain on ecosystems and minimizing waste generation.

In conclusion, investing in high-quality equipment for plastic recycling extruders offers a multitude of benefits. From enhanced efficiency and productivity to superior quality output, high-quality extruders play a pivotal role in mitigating plastic waste and promoting a sustainable circular economy. Moreover, the reduced environmental impact, cost savings, and economic benefits make investing in high-quality equipment a viable choice for businesses and organizations seeking to contribute to a cleaner and greener future. By embracing high-quality equipment in plastic recycling extruders, we can pave the way towards a more sustainable and environmentally responsible plastic industry.

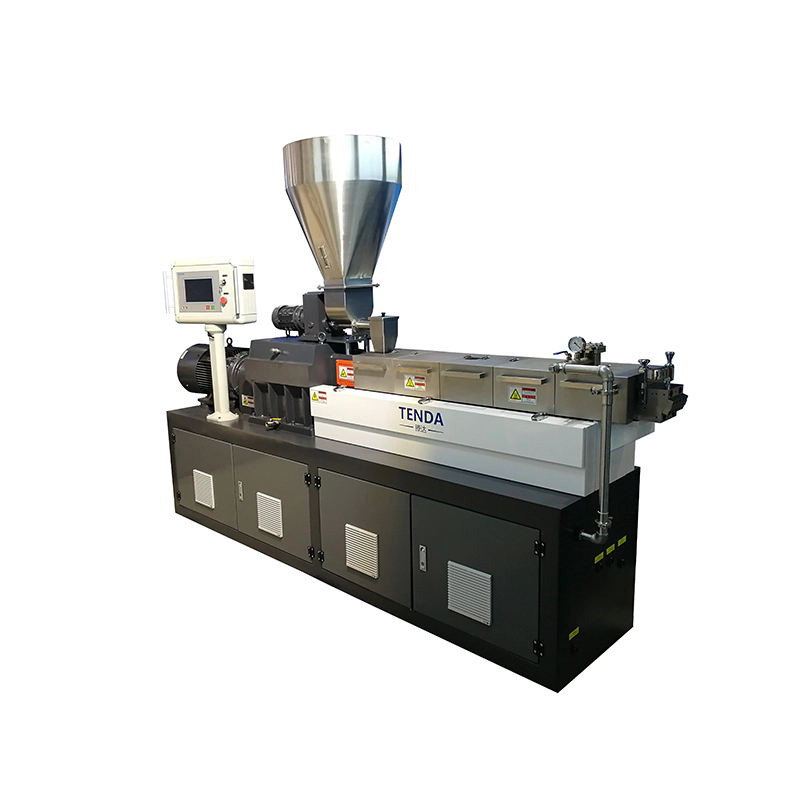

Nanjing Tengda Machinery Co., Ltd. thinks that that firms can avoid the artificial choice between quantitative and qualitative risk management, allowing both to play important roles in surfacing and assessing risks.

If you need Application solution, you should always consult a professional provider. Nanjing Tengda Machinery Co., Ltd. is one such a competent provider that is highly qualified to offer a wide range of products and services. Visit today!

Nanjing Tengda Machinery Co., Ltd. integrates research streams on team diversity and knowledge boundaries, and present a framework that considers the kinds of specific knowledge boundaries that must be spanned to achieve high-level, cross-boundary teaming.