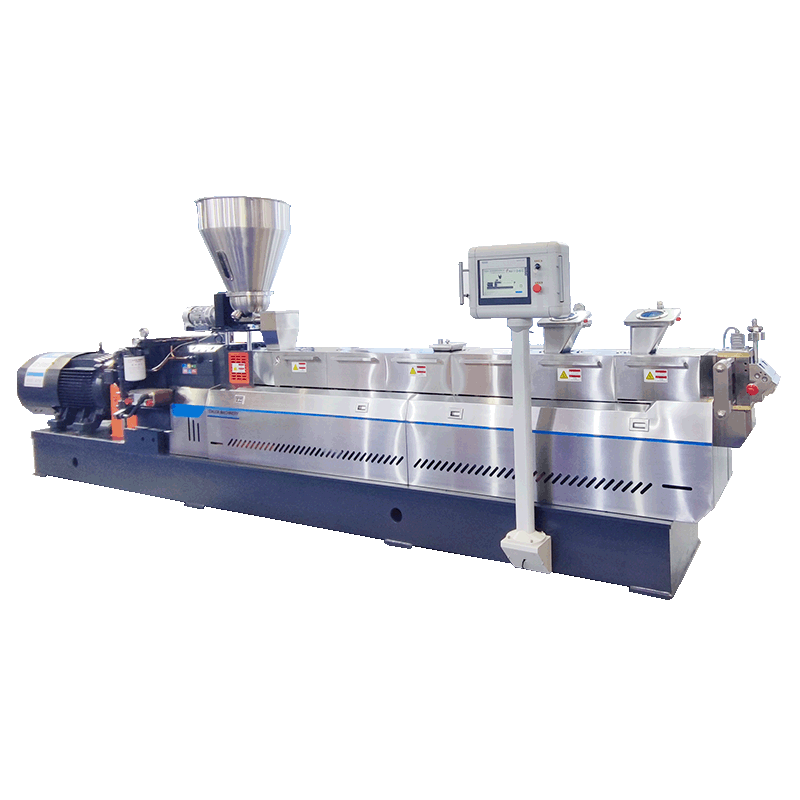

Plastic Waste Extruder Machine: The Benefits of Automation and Robotics

Introduction

The issue of plastic waste has become a pressing concern across the globe. With the ever-increasing consumption and disposal of plastic products, finding sustainable solutions to manage this waste has become imperative. One such solution is the Plastic Waste Extruder Machine, which combines the power of automation and robotics to effectively tackle the problem. This innovative technology offers a range of benefits that not only streamline the recycling process but also contribute to a cleaner and more sustainable environment. In this article, we will delve deeper into the advantages of automation and robotics in plastic waste extrusion, highlighting their significant impact on waste management.

The Rise of Plastic Waste

Plastic waste has reached alarming levels in recent years due to its widespread use in various industries. From packaging materials to consumer goods, plastics have become an indispensable part of our daily lives. However, the improper disposal and inefficient recycling of plastic waste have led to detrimental consequences for the environment. According to a study conducted by the United Nations Environment Programme (UNEP), only 9% of the 9 billion tonnes of plastic waste produced worldwide has been recycled. This staggering figure highlights the urgent need for advanced technologies to tackle the growing plastic waste crisis.

The Need for Automation and Robotics

Traditional methods of plastic waste recycling often rely on manual labor, which can be time-consuming, inefficient, and labor-intensive. Here is where automation and robotics play a crucial role. By automating key processes in plastic waste extrusion, these technologies streamline the entire recycling process, enhancing its efficiency and accuracy. Automation eliminates the need for extensive manual labor, reducing labor costs and preventing human error. On the other hand, robotics adds another layer of precision and control, ensuring consistent and high-quality output. Together, automation and robotics offer a sustainable solution to plastic waste management, enabling the recycling industry to cope with the increasing demands efficiently.

The Advantages of Automation in Plastic Waste Extrusion

Automation in plastic waste extrusion brings a myriad of advantages that revolutionize the recycling process. Let's explore some of these benefits:

Increased Efficiency and Productivity:

Automation allows for continuous operation, significantly increasing overall efficiency and productivity. Unlike manual labor, automated machines can operate 24/7 without the need for breaks or shifts. This continuous operation enables higher output and reduces turnaround time, crucial factors for meeting the ever-growing demand for recycled plastic products.

Improved Quality Control:

Automation systems are equipped with advanced sensors and monitoring capabilities, ensuring precise control over the extrusion process. These systems can detect any deviations or anomalies in real-time, allowing for immediate adjustments or interventions. As a result, the quality of the extruded plastic products remains consistently high, meeting industry standards and customer expectations.

Reduced Labor Costs:

By automating the recycling process, the dependency on manual labor is significantly reduced. This leads to substantial cost savings in terms of wages, benefits, and training expenses. Moreover, automation eliminates the risk of human error and the associated costs of rework or product defects. It allows industries to allocate their resources more efficiently and invest in further research and development.

Sustainability and Environmental Impact:

Plastic waste extruder machines equipped with automation technology contribute to a more sustainable and eco-friendly approach to recycling. They enable the efficient processing of a wide range of plastic waste materials, reducing the burden on landfills and minimizing the need for incineration, which can release harmful toxins into the atmosphere. By promoting recycling over conventional waste disposal methods, automation helps conserve natural resources and reduce carbon emissions.

Enhanced Safety:

Automation and robotics in plastic waste extrusion not only optimize productivity but also enhance workplace safety. These technologies eliminate the need for workers to perform hazardous tasks, reducing the risk of accidents and injuries. Workers can be assigned to more meaningful and less physically demanding roles, ensuring a safer working environment for all.

Robotics in Plastic Waste Extrusion

While automation plays a vital role in improving the efficiency of plastic waste extrusion, the integration of robotics takes the process to a whole new level. Robotics brings a multitude of benefits that complement the advantages provided by automation. Let's discover how robotics revolutionizes plastic waste extrusion:

Higher Precision and Accuracy:

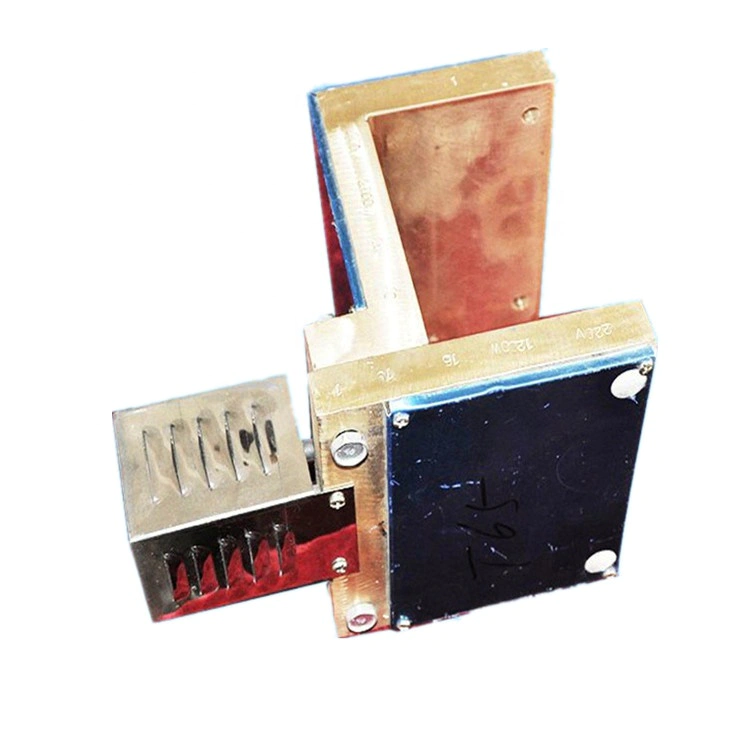

Robotic systems are designed with high precision and accuracy, ensuring consistent and uniform extrusion of plastic materials. These machines can precisely control parameters such as temperature, pressure, and speed, resulting in high-quality products with minimal variations. This level of precision contributes to improving the overall reliability of recycled plastic products.

Flexibility and Adaptability:

Robotic systems are incredibly versatile and can be easily programmed to handle different types of plastic waste. Through the use of advanced software and artificial intelligence, robots can adapt to varying shapes, sizes, and properties of plastic materials, making the recycling process more efficient and adaptable. This flexibility allows recycling facilities to handle a wide range of plastic waste streams, maximizing their recycling capabilities.

Minimization of Waste:

Robotics enables the optimization of material usage, minimizing waste during the extrusion process. By accurately measuring and dispensing plastic materials, robots ensure that there is no excess or inadequate supply. The reduction in waste not only contributes to cost savings but also promotes sustainability and efficient resource utilization.

Enhanced Speed and Throughput:

Robots are capable of high-speed operations, significantly increasing the throughput of the plastic waste extrusion process. Their ability to perform repetitive tasks at a consistent pace reduces the time required for each cycle and improves overall productivity. With faster processing times, recycling facilities can meet the growing demand for recycled plastic products more effectively.

Conclusion

The Plastic Waste Extruder Machine with automation and robotics brings several advantages that undoubtedly revolutionize the recycling industry. The combination of automation and robotics significantly enhances the efficiency, quality, and sustainability of the plastic waste extrusion process. From increased productivity and improved quality control to reduced labor costs and enhanced safety, these technologies offer a comprehensive solution to tackle the escalating plastic waste crisis. By embracing automation and robotics, we can pave the way for a greener future, where plastic waste is effectively managed, and valuable resources are conserved for generations to come.+

is a modern Application widely used in plastic extruder machine manufacturers industry. It also enhances the quality extruder machine manufacturers value of the products.

For more information please see our site at TENGDA Extruder Machine Manufacturers. Don't be hesitate to contact us!

If Nanjing Tengda Machinery Co., Ltd. added selling plans, offered more Application, and increased service regions, it would suit the needs of more users.

Deeper connections between Nanjing Tengda Machinery Co., Ltd. and customers can be made when we're thinking out of the box and meeting outside of manufacturing work.

To stay in contact for latest review of Application plastic extruder machine manufacturers across the globe and find out quality products, just go to TENGDA Extruder Machine Manufacturers.