Professional PVC Compounding Extruder Line Manufacturer - Discover Our Solutions

Are you looking for state-of-the-art solutions for your PVC compounding requirements? Finding the right equipment that meets modern industrial standards might seem overwhelming, but understanding what sets professional extruder lines apart from the rest can make a world of difference in your operation. In this comprehensive guide, we delve into the intricate world of PVC compounding extruder lines to help you discover why our solutions are the industry’s top choice. Read on to explore everything from the latest technological advancements to the benefits of choosing our manufacturing solutions.

Introduction to PVC Compounding Extruder Lines

PVC compounding is a sophisticated process involving various ingredients, such as PVC resin, plasticizers, stabilizers, and other additives, to achieve the desired properties and performance characteristics. The extruder line is the backbone of this process, ensuring consistent quality and efficient production.

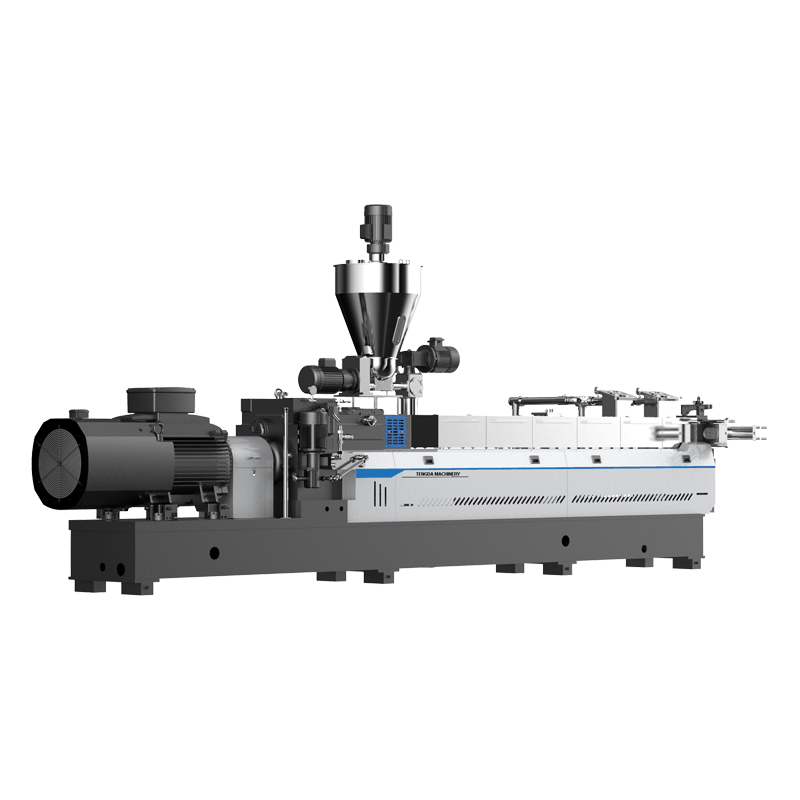

A PVC compounding extruder line typically consists of several critical components: hoppers for raw materials, twin-screw extruders for mixing and melting, and downstream equipment for cooling, cutting, and packaging. Each of these components plays a vital role in the overall performance and reliability of the extruder line.

The choice of extruder line can have a long-lasting impact on your business. Not only does it affect the quality of your PVC compounds, but it also influences production rates, operational costs, and energy consumption. That’s why opting for professional-grade equipment is crucial in staying ahead in a competitive market.

Technological Advancements in PVC Compounding

In today's fast-paced market, technological innovation is transforming the landscape of PVC compounding. State-of-the-art extruders are equipped with cutting-edge features such as advanced control systems, automated monitoring, and precision-engineered components that optimize efficiency and consistency.

One significant technological advancement in PVC compounding has been the development of smart extruder lines. These systems are integrated with IoT (Internet of Things) capabilities, enabling real-time monitoring of the entire production process. This form of advanced data analytics can significantly reduce downtime, waste, and operational costs by predicting maintenance needs and optimizing performance metrics.

Moreover, modern extruder lines now incorporate energy-efficient designs. The use of variable frequency drives (VFDs) allows motors to adjust their speed according to operational demands, leading to substantial energy savings. Additionally, improved screw designs and advanced thermal regulation methods contribute to better mixing quality and lower energy consumption.

Lastly, automation is revolutionizing the PVC compounding process. Automatic feeders, in-line quality control systems, and robotic assistive devices streamline production, minimize human error, and improve safety. High-tech automation also facilitates quick changeovers and flexible manufacturing, making it easier to adapt to different PVC formulations and production requirements.

Our Range of PVC Compounding Extruder Lines

When it comes to a range of solutions, our PVC compounding extruder lines cater to diverse industrial needs. Whether you're producing rigid PVC for piping or flexible compounds for flooring, our extruder lines are built to handle various applications with finesse.

Our offerings include several models of twin-screw extruders, each designed to meet specific production capacities and technical requirements. The high-torque, high-speed extruders ensure efficient mixing and compounding, which is essential for producing top-quality PVC compounds. Advanced screw configurations and barrel designs ensure maximum dispersion of additives, achieving uniformity and consistency in every batch.

Moreover, our extruder lines are customized to integrate seamlessly with your existing infrastructure. Modular designs enable easy upgrades and scaling, ensuring that your investment is future-proof. Whether you need compact solutions for limited space or large-scale setups for mass production, we have options to meet your needs.

We also offer comprehensive after-sales support, including installation, training, and maintenance services. Our team of skilled technicians is always on hand to ensure your extruder line operates at peak efficiency. With a strong focus on customer satisfaction, our solutions are engineered to provide reliable and consistent performance year after year.

Benefits of Choosing Our PVC Compounding Solutions

Why should you choose our PVC compounding extruder lines? For starters, our systems are renowned for their unparalleled reliability and efficiency. Engineered with precision, our extruder lines deliver consistent high-quality output, thereby significantly reducing waste and operational costs.

One of the primary benefits of choosing our solutions is the exceptional quality control they offer. Advanced measurement and monitoring systems ensure that every batch of PVC compound meets stringent quality standards. Real-time data analytics allow for fine-tuning of the process, ensuring optimal performance at all times.

Energy efficiency is another key advantage. Our extruder lines are designed to minimize energy consumption, thereby reducing your overall production costs. Environmentally friendly features, such as energy-saving motors and efficient cooling systems, make our equipment a sustainable choice.

Flexibility is also a hallmark of our solutions. Our extruder lines can be easily adapted to cater to various formulations and production requirements. Quick changeover features and intuitive control interfaces simplify the process of switching between different production runs, thus enhancing productivity.

Furthermore, our comprehensive support services ensure minimal downtime and operational disruptions. From initial installation to ongoing maintenance, our team of experts is committed to providing you with the highest level of service and support.

Case Studies: Success Stories from Our Clients

To better illustrate the impact of our PVC compounding extruder lines, let's explore some real-world success stories from our clients. These case studies highlight the tangible benefits that businesses have experienced by choosing our solutions.

One of our clients, a leading manufacturer of PVC pipe, was struggling with inconsistency in product quality due to outdated equipment. After upgrading to our high-torque twin-screw extruder line, the company reported a 30% improvement in product consistency and a 20% reduction in material waste. The advanced control systems ensured precise temperature management and uniform dispersion of additives, leading to superior quality pipes that met international standards.

Another client, specializing in flexible PVC compounds for automotive interiors, faced challenges with production scalability and energy consumption. By integrating our automated extruder line with IoT monitoring, the client achieved a 25% increase in production capacity while reducing energy consumption by 15%. The automation features also streamlined the quality control process, ensuring every batch met the required specifications with minimal human intervention.

A third client, a producer of high-performance PVC flooring, needed a versatile solution capable of handling multiple formulations. Our modular extruder line provided the flexibility needed to switch between different products rapidly. This flexibility resulted in a 35% boost in productivity and allowed the client to expand their product range without significant additional investment.

These success stories are a testament to the reliability and efficiency of our PVC compounding extruder lines. By choosing our solutions, these businesses have not only enhanced their production capabilities but also achieved significant cost savings and improved product quality.

In conclusion, selecting the right PVC compounding extruder line can be a game-changer for your business. From the latest technological advancements to the wide range of solutions we offer, our extruder lines are designed to meet the stringent demands of modern industrial applications. By opting for our professional equipment, you gain access to state-of-the-art technology, unparalleled efficiency, and comprehensive support services that ensure long-term operational success. Whether you’re looking to enhance product quality, improve energy efficiency, or expand your production capacity, our PVC compounding solutions are built to deliver exceptional performance across the board.

Explore our solutions today and discover the difference that professional-grade equipment can make. With a strong focus on innovation, customer satisfaction, and sustainability, we are committed to helping you achieve your production goals and stay ahead in a competitive market.

Looking for an innovative range of extruder machine manufacturers Application products? Nanjing Tengda Machinery Co., Ltd. supplies a diverse range of consumer, commercial and specialty industrial products including Application, plastic extruder machine manufacturers, extruder machine manufacturers,etc.Click TENGDA Extruder Machine Manufacturers to learn more!

Nanjing Tengda Machinery Co., Ltd. strives to be the acknowledged global leader and preferred partner in helping our clients succeed in the world’s rapidly evolving financial markets.

To deal with commercial threats, Nanjing Tengda Machinery Co., Ltd. konws that the notion of proactively seeking out potential or looming external threats against a company is gaining traction.