PVC Extruder Machine: Key Features to Consider Before Investing

Are you considering investing in a PVC extruder machine? With the growing demand for PVC products in various industries, such as construction, automotive, and packaging, it's crucial to choose the right equipment to meet your production needs. The market offers a wide range of PVC extruder machines, each with its own set of features and capabilities. To ensure that you make an informed decision, it's essential to understand the key features and factors to consider. In this article, we will discuss the crucial aspects of a PVC extruder machine that you should keep in mind before making the investment.

The Importance of Selecting the Right PVC Extruder Machine

PVC extruder machines play a vital role in the manufacturing process of PVC products. These machines are responsible for melting and molding the PVC material into the desired shape and form. Choosing the right extruder machine is critical for achieving high-quality and consistent output while maximizing productivity. By considering the key features of a PVC extruder machine, you can ensure efficient operation, reduced downtime, and increased profitability.

1. Extruder Type and Capacity

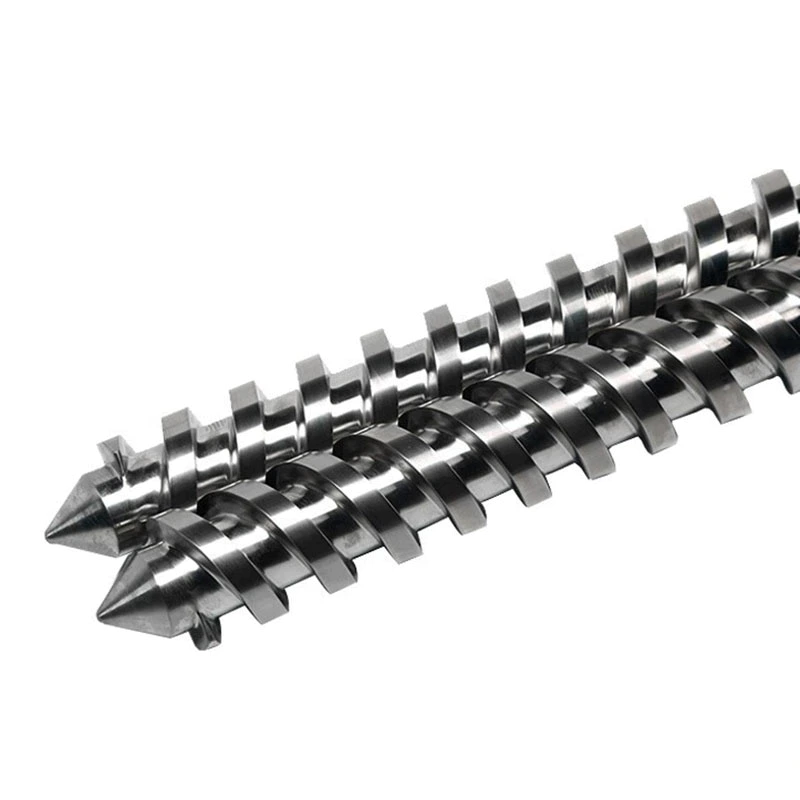

One of the first factors to consider when investing in a PVC extruder machine is the type of extrusion process you require and the production capacity. PVC extrusion processes can be broadly categorized into two types: single screw extruders and twin screw extruders.

Single screw extruders are commonly used for PVC processing applications and are ideal for producing products that require a uniform shape and texture. These machines are suited for low to medium production rates and offer simplicity and cost-effectiveness.

On the other hand, twin screw extruders provide enhanced mixing capabilities, making them suitable for more complex PVC products that require specialized formulations. They offer a higher degree of process control and are typically used for high-volume production.

The capacity of the extruder machine should align with your production requirements. It is vital to evaluate the output rate, expressible in kilograms per hour (kg/h), to ensure that the machine can meet your desired production goals. Consider factors such as product complexity, desired production volume, and market demand while selecting the capacity of the PVC extruder machine.

2. Quality and Consistency of Output

The quality and consistency of the output are crucial factors in determining the success of your PVC extrusion operations. Look for features that contribute to producing uniform and defect-free PVC products. Here are some key aspects to consider:

Automatic Temperature Control: An extruder machine equipped with automatic temperature control ensures precise and consistent temperature regulation throughout the extrusion process. This feature helps prevent thermal variations that can affect PVC consistency, reducing the chance of defects.

Screw Design and Cooling System: The screw design of the extruder machine influences the mixing and melting of the PVC material. Look for machines that offer optimal screw design and efficient cooling systems, as these factors contribute to a consistent output and minimize the risk of material degradation.

Advanced Filtration Systems: Filtration systems are crucial for removing impurities and contaminants from the PVC melt. Systems with multiple stages of filtration, including finer screens and melt pumps, help ensure a clean melt, resulting in high-quality products.

3. Energy Efficiency and Operating Costs

Investing in an energy-efficient PVC extruder machine not only benefits the environment but also your bottom line. Look for features that contribute to reducing energy consumption and operating costs, such as:

Advanced Heating Technology: Machines that utilize advanced heating technologies, such as infrared heating, can significantly reduce the energy required for melting the PVC material. This not only reduces operating costs but also minimizes temperature variations, resulting in a more consistent output.

Efficient Cooling Systems: Cooling systems that optimize the use of water or air can help enhance energy efficiency. Look for extruder machines that integrate intelligent cooling systems to minimize energy consumption and reduce water usage.

Drive System: The drive system of the extruder machine also plays a significant role in energy efficiency. Machines equipped with energy-efficient motors and variable frequency drives (VFD) allow for better control over motor speed and power consumption, reducing energy waste.

Considering energy efficiency and operating costs can lead to long-term savings and a greener manufacturing process.

4. Ease of Operation and Maintenance

Investing in a PVC extruder machine that offers ease of operation and maintenance can increase overall productivity and minimize downtime. Look for the following features to ensure a smooth workflow:

User-Friendly Interface: Machines equipped with a user-friendly interface and intuitive controls make it easy for operators to set parameters and monitor the extrusion process. Clear indicators, informative displays, and easily accessible controls contribute to a hassle-free operation.

Quick Changeovers: Look for machines that offer quick and efficient changeover capabilities. This allows for easy transitioning between different products or formulations, reducing downtime and increasing production flexibility.

Easy Access for Maintenance: Machines with well-designed access points and maintenance-friendly features, such as easily removable components and clear documentation, simplify routine maintenance tasks and reduce the time required for servicing.

5. Reliability and Technical Support

Reliability is a key factor to consider while selecting a PVC extruder machine, as downtime can lead to significant losses in production and revenue. Look for machines from reputable manufacturers known for their reliability and product warranties. A reliable machine should demonstrate:

Robust Construction: The machine should be built with high-quality materials and components that can withstand the rigorous demands of PVC extrusion. Strong construction ensures long-term durability and minimizes the risk of breakdowns.

Technical Support and After-Sales Service: Choosing a manufacturer that offers reliable technical support and after-sales service ensures that you have assistance whenever required. Excellent customer support can help troubleshoot issues quickly, minimizing downtime and optimizing machine performance.

Summary

Investing in a PVC extruder machine requires careful consideration of various key features and factors. By choosing the right extruder type and capacity, ensuring high-quality and consistent output, prioritizing energy efficiency and operating costs, focusing on ease of operation and maintenance, and selecting a reliable machine with excellent technical support, you can maximize the productivity and profitability of your PVC extrusion operations. Take the time to evaluate different options, consult with experts, and gather all the necessary information before making your investment. Remember, selecting the right PVC extruder machine is a crucial step toward achieving success in the competitive market of PVC products.

In the present growing world of emerging technology, the has demanding operation in various sectors like plastic extruder machine manufacturers, extruder machine manufacturers, plastic extruder machine manufacturers and many other industries at extruder machine manufacturers levels of manufacturing and designing.

Deliver value to our customers by providing the most reliable and efficient products as Application.

Nanjing Tengda Machinery Co., Ltd.'s main technology of Application leads us to understand and utilize information correctly.

Application allows users to apply in different ways for satisfying their needs.

To derive the optimal value out of plastic extruder machine manufacturers Application for your home, make sure they're purchased from a globally certified organization to ensure quality in use. Such an offer can be found at TENGDA Extruder Machine Manufacturers.