PVC Extruders: The Pros and Cons of This Popular Material

Introduction

When it comes to the world of manufacturing and construction, finding the right materials can make all the difference. One widely-used material that has become a staple in various industries is PVC, or polyvinyl chloride. PVC is a versatile and durable thermoplastic that can be found in a myriad of products, ranging from pipes and window frames to clothing and electrical cables. One crucial aspect of working with PVC is the use of PVC extruders. In this article, we will delve into the pros and cons of this popular material and explore how PVC extruders play a crucial role in its fabrication.

Understanding PVC Extruders

Definition and Function of PVC Extruders

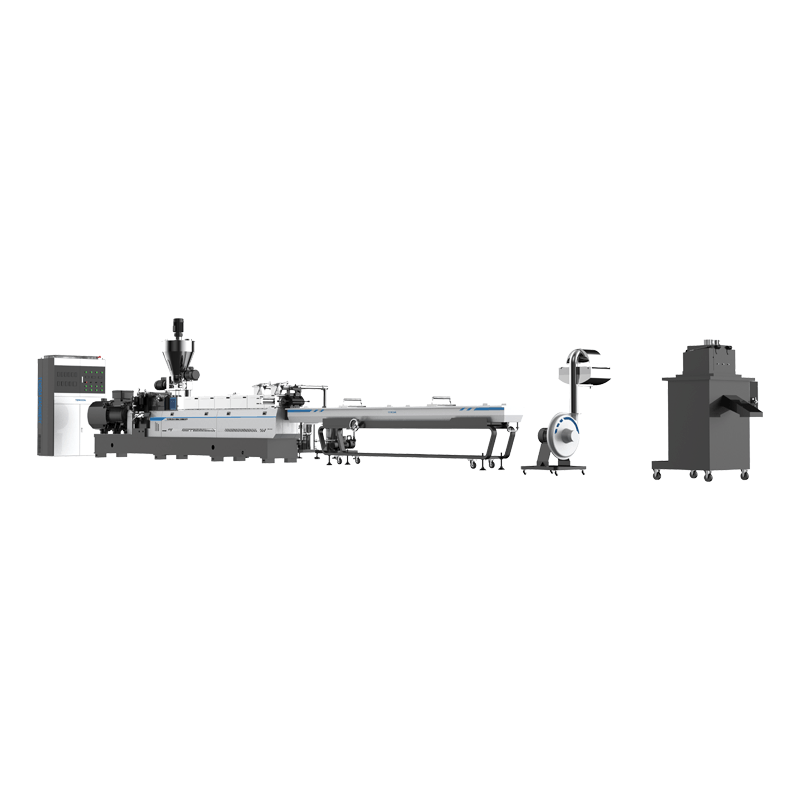

PVC extruders are specialized machines used in the process of PVC extrusion. Extrusion is a manufacturing technique that involves melting a material and then forcing it through a die to create a continuous profile or shape. In the case of PVC, the extrusion process allows for the creation of various products of different sizes, designs, and functionalities.

PVC extruders consist of a hopper, a heating element, a screw mechanism, and a die. The PVC material is fed into the hopper, where it is then heated to its melting point using the heating element. Once the PVC is molten, it is pushed forward by the screw mechanism through the die, which determines the shape and size of the final product. The extruded PVC then goes through a cooling process to solidify before it can be cut into the desired lengths or further processed.

The Pros of PVC Extruders

Cost-Effective Production

One of the significant advantages of PVC extruders is their cost-effectiveness in the production of PVC products. PVC is a highly affordable material, making it an attractive option for manufacturers and builders alike. When combined with the efficiency of extrusion processes, PVC extruders allow for high-volume production at a lower cost per unit. This cost-effectiveness is particularly beneficial for industries that rely heavily on PVC products, such as the construction and automotive sectors.

Design Flexibility

PVC extruders offer incredible design flexibility, allowing for the creation of a wide range of products with varying shapes, sizes, and features. The ability to customize the die used in the extrusion process enables manufacturers to produce PVC profiles and structures tailored to their specific requirements. Whether it's window frames with intricate designs or piping systems with complex geometries, PVC extruders can accommodate a vast array of design possibilities.

Durability and Low Maintenance

PVC is known for its exceptional durability and low maintenance requirements, and this extends to PVC products created through extrusion. PVC extruded items excel in their resistance to corrosion, impact, and weathering, making them ideal for outdoor applications or environments with harsh conditions. Additionally, PVC extruders themselves are built to withstand the wear and tear of continuous operation, ensuring longevity and minimizing the need for frequent repairs or replacements.

Recyclability

Sustainability is a growing concern in today's manufacturing landscape. PVC extruders contribute to the sustainable production of PVC products by enabling recycling and reusability. PVC waste generated during the extrusion process or from post-consumer PVC products can be collected, recycled, and reintroduced into the extrusion process. This reduces waste and conserves resources, making PVC extrusion a more environmentally friendly option compared to other manufacturing techniques.

Energy Efficiency

Another advantage of PVC extruders is their energy efficiency. Modern PVC extrusion machines are designed to minimize energy consumption while maintaining high productivity levels. Efficient heating systems, optimized screw mechanisms, and advanced control technologies contribute to reducing energy requirements during the extrusion process. This not only lowers production costs but also reduces the carbon footprint associated with PVC production.

The Cons of PVC Extruders

Environmental Concerns

While PVC extruders offer several advantages, it is essential to address the environmental concerns associated with this popular material. PVC is made from fossil fuels, primarily natural gas and petroleum. The production of PVC involves the release of toxic chemicals, such as dioxins or chlorine, which can have adverse effects on the environment and human health. Additionally, the disposal of PVC products can be problematic, as PVC takes a considerable amount of time to naturally decompose.

Health Risks

Another drawback of PVC extruders lies in the potential health risks associated with prolonged exposure to PVC and its additives. During the extrusion process, PVC may release volatile organic compounds (VOCs) and other hazardous substances. Workers operating PVC extruders must follow stringent safety protocols and utilize protective equipment to minimize exposure to harmful emissions. Additionally, users of PVC products, such as consumers or construction workers, should be aware of potential health risks and take appropriate precautions.

Limitations in High-Temperature Applications

While PVC is known for its versatility, it has limitations when it comes to high-temperature applications. PVC can start to soften or deform under high temperatures, which restricts its use in certain environments. For applications that require exposure to extreme heat or fire resistance, other materials like metals or specialized polymers may be more suitable. It is crucial to consider the intended application and the operating conditions when deciding whether PVC extrusion is the right manufacturing method.

Difficulties in Recycling Certain PVC Products

While PVC itself is recyclable, certain PVC products pose challenges in the recycling process. For instance, PVC products may contain additives or composite materials that make them less compatible with standard recycling methods. This can limit the recyclability of specific PVC items and result in a higher amount of PVC waste in landfills. However, ongoing research and advancements aim to overcome these challenges and improve the recycling capabilities of PVC products.

Conclusion

PVC extruders play a vital role in the production of a wide range of PVC products. They offer numerous advantages, including cost-effective production, design flexibility, durability, recyclability, and energy efficiency. However, it is crucial to acknowledge the environmental concerns, health risks, limitations in high-temperature applications, and difficulties in recycling certain PVC products that come with the use of PVC extruders. By weighing the pros and cons and making informed decisions, manufacturers can harness the benefits of PVC extrusion while striving to minimize its potential drawbacks. With ongoing research and advancements, the future of PVC extrusion holds promise for even more sustainable and innovative applications.

Looking for an innovative range of plastic extruder machine manufacturers Application products? Nanjing Tengda Machinery Co., Ltd. supplies a diverse range of consumer, commercial and specialty industrial products including Application, extruder machine manufacturers, plastic extruder machine manufacturers,etc.Click TENGDA Extruder Machine Manufacturers to learn more!

You can count on Nanjing Tengda Machinery Co., Ltd. to be your one stop shopping site for most of the quality products you are searching for. We strive to offer a wide variety of products for you to learn about and to purchase.

A quality monitoring group created for ensuring that Nanjing Tengda Machinery Co., Ltd. manufactures Application accoording the strictest standard.

Application can be applied in different ways as extruder machine manufacturers.