PVC Extrusion Machine: Advanced Features That Can Improve Your Productivity

Introduction:

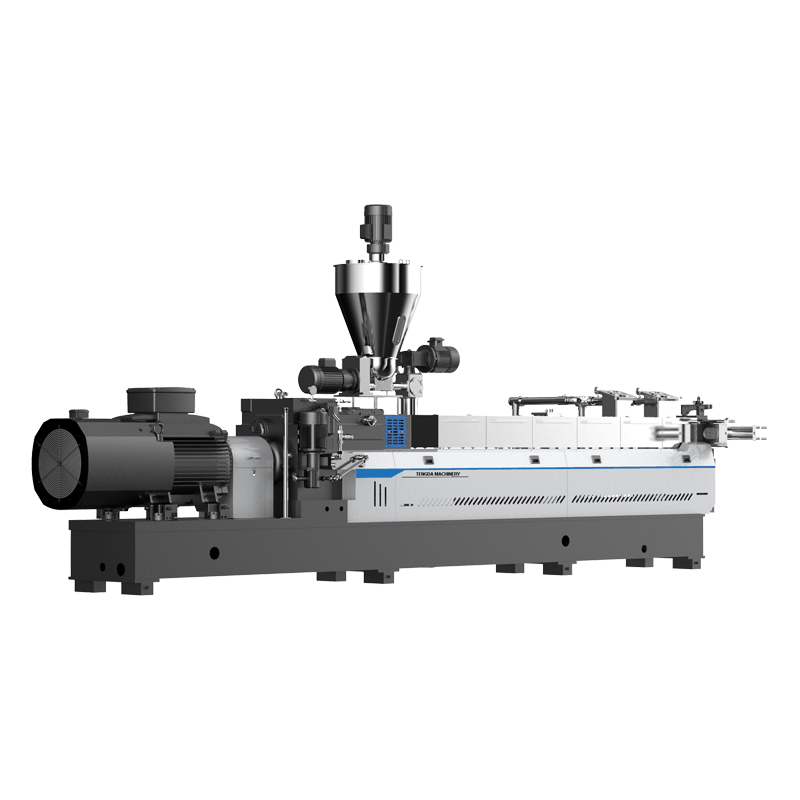

PVC extrusion machines have revolutionized the manufacturing industry, enabling companies to enhance their productivity and efficiency in the production of PVC products. These advanced machines are equipped with remarkable features that streamline the extrusion process, resulting in higher output rates and superior product quality. Whether you are in the construction, automotive, or packaging industry, investing in a state-of-the-art PVC extrusion machine can significantly boost your productivity and meet the ever-increasing demands of your customers. In this article, we explore some of the advanced features that these machines offer, highlighting their potential to revolutionize your manufacturing processes.

Increased Precision and Control

Precision and control are critical factors when it comes to producing PVC extrusions. With traditional extrusion methods, maintaining a precise and consistent product profile can be challenging. However, advanced PVC extrusion machines incorporate cutting-edge technology to ensure superior precision and control throughout the production process.

These machines are equipped with advanced control panels that allow operators to adjust various parameters, such as temperature, pressure, and speed. By fine-tuning these parameters, manufacturers can achieve accurate and consistent extrusion profiles, reducing wastage and improving overall product quality. The user-friendly interface of these machines enables operators to monitor and make real-time adjustments, ensuring optimal extrusion conditions and minimizing the chances of defects or inconsistencies.

Furthermore, some PVC extrusion machines offer integrated data logging and analysis capabilities. This feature allows manufacturers to monitor and analyze extrusion parameters over time, facilitating process optimization and identifying areas for improvement. By leveraging this data-driven approach, companies can enhance their productivity, reduce downtime, and ultimately deliver high-quality PVC products to their customers.

Enhanced Efficiency and Speed

Traditional extrusion methods often struggle to meet the growing demand for PVC products, primarily due to their limited efficiency and speed. However, modern PVC extrusion machines are designed to address these challenges, enabling manufacturers to streamline their production processes and achieve higher output rates.

One key feature that enhances efficiency is the incorporation of advanced heating systems. These machines utilize energy-efficient heating elements that rapidly heat the PVC material, reducing the time required for heating and melting. This results in faster production cycles and increased overall productivity.

Additionally, some PVC extrusion machines feature multi-zone temperature control systems. These systems divide the extrusion barrel into different zones, each equipped with independent temperature control capabilities. By precisely controlling the heating of different zones, these machines ensure optimal heat distribution throughout the extrusion process, minimizing energy consumption and enhancing overall efficiency.

Furthermore, advanced PVC extrusion machines often come with automatic feeding and material handling systems. These systems eliminate the need for manual intervention in material loading, reducing human error and increasing production speed. The automated material handling also enables continuous, uninterrupted production runs, maximizing productivity and minimizing downtime.

Improved Product Quality and Consistency

Product quality is of utmost importance in any manufacturing process, and PVC extrusion is no exception. The advanced features offered by PVC extrusion machines contribute significantly to improving product quality and consistency, meeting the requirements and expectations of customers.

One crucial feature that enhances product quality is the integration of advanced cooling systems. These systems ensure efficient and uniform cooling of the extruded PVC profiles, preventing deformations, warping, or other defects caused by improper cooling. By maintaining consistent cooling conditions, manufacturers can achieve precise product dimensions and excellent surface finishes, meeting the strict quality standards demanded by various industries.

Moreover, PVC extrusion machines with advanced calibration systems offer precise control over the product dimensions. These systems allow operators to adjust the calibration parameters during the extrusion process, ensuring accurate and consistent product profiles. By eliminating dimensional variations, manufacturers can ensure that each extruded PVC product meets the required specifications and satisfies customer expectations.

Advanced PVC extrusion machines also incorporate cutting-edge cutting and finishing technologies. These machines offer precise cutting mechanisms that ensure clean and accurate cuts. Additionally, they come with advanced finishing features such as embossing, punching, or engraving capabilities, enabling manufacturers to enhance the aesthetics and functionality of the final PVC products.

Seamless Integration with Automation

Automation plays a crucial role in modern manufacturing environments, and PVC extrusion machines are designed to seamlessly integrate with automated systems. This integration allows for enhanced productivity, improved process control, and reduced human intervention.

Advanced PVC extrusion machines can be integrated into complex production lines that include automated material handling, quality control, and packaging systems. By automating the entire extrusion process, manufacturers can achieve consistent and efficient production runs without the need for constant manual supervision. This not only increases productivity but also reduces labor costs and minimizes the chances of human error.

Furthermore, the integration with automation enables real-time data exchange between different machines and systems. This interconnectivity enhances process monitoring and control, as well as facilitates efficient data analysis. Manufacturers can leverage this connectivity to implement predictive maintenance strategies, optimize production parameters, and ensure maximum uptime and efficiency of the PVC extrusion line.

Environmental Sustainability

With the increasing focus on environmental sustainability, PVC extrusion machines incorporate features that promote energy efficiency and waste reduction. These machines adhere to strict environmental standards, allowing manufacturers to produce PVC products responsibly while minimizing their carbon footprint.

The energy-efficient heating elements and multi-zone temperature control systems reduce energy consumption during the extrusion process. By minimizing energy waste, manufacturers can contribute to reducing greenhouse gas emissions and conserving resources.

Additionally, PVC extrusion machines are designed to reduce material wastage. The precise control over extrusion parameters and the integration of automatic material handling systems significantly reduce material scrap and rework. This not only saves costs but also reduces the environmental impact associated with material wastage.

Summary:

PVC extrusion machines have emerged as technological marvels in the manufacturing industry, offering a wide range of advanced features that improve productivity and product quality. With enhanced precision and control, manufacturers can achieve accurate and consistent extrusion profiles while minimizing defects. The increased efficiency and speed of these machines enable higher output rates and improved overall efficiency. Furthermore, the machines ensure excellent product quality and consistency through advanced cooling, calibration, cutting, and finishing technologies. The seamless integration with automation allows for streamlined production processes and reduced human intervention, leading to enhanced productivity and reduced labor costs. Lastly, the emphasis on environmental sustainability in PVC extrusion machines promotes energy efficiency and waste reduction, aiding companies in their commitment to responsible and eco-friendly manufacturing practices. By investing in a state-of-the-art PVC extrusion machine, businesses can benefit from these advanced features and stay ahead in today's competitive market.