PVC Extrusion Machine: An Overview of Its Features and Capabilities

Plastic extrusion is a manufacturing process used to create a wide range of products, especially those made from thermoplastic materials. One of the most commonly used extrusion machines is the PVC extrusion machine, which is specifically designed for processing polyvinyl chloride (PVC) resin. This versatile machine offers a plethora of features and capabilities that make it an indispensable tool in various industries. In this article, we will delve into the intricacies of the PVC extrusion machine, exploring its key features and the vast capabilities it brings to the table.

The History of PVC Extrusion Machines

Before we dive into the various features and capabilities of PVC extrusion machines, it's essential to understand their historical background. The concept of plastic extrusion originated in the early 19th century when a small plastic tube was extruded using celluloid material. However, it wasn't until the 1940s that PVC was introduced as a viable material for extrusion. Since then, PVC extrusion machines have evolved tremendously, becoming highly efficient and versatile production tools.

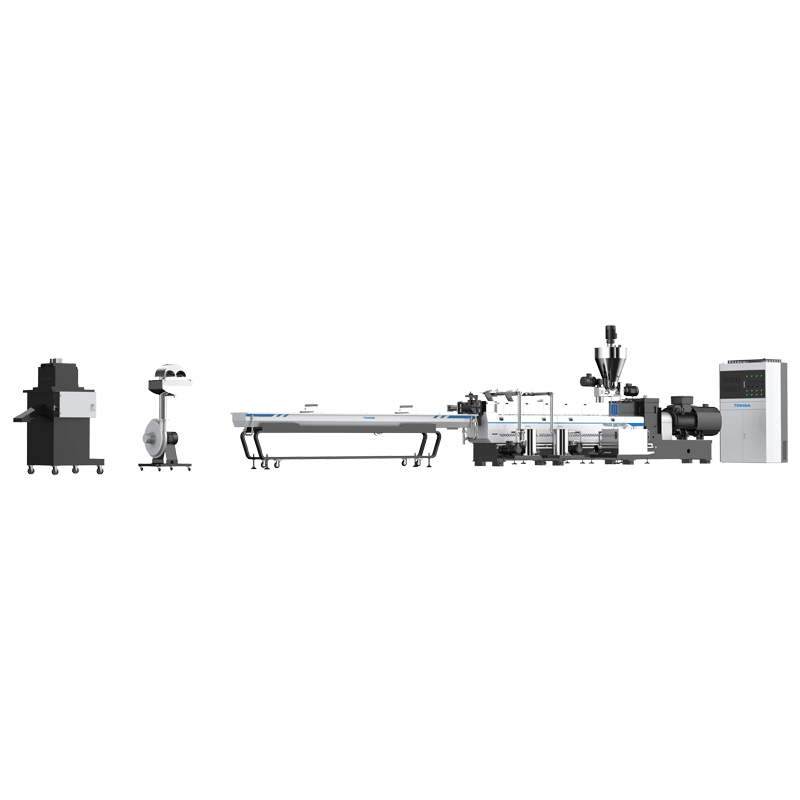

The Working Principle of PVC Extrusion Machines

PVC extrusion machines operate on a simple yet effective principle. The process begins with the heating and melting of PVC resin, which is then fed into the extruder's hopper. The extruder comprises a rotating screw that conveys the molten PVC through a barrel. The barrel is heated to maintain the desired temperature, ensuring optimal flow and viscosity of the PVC material. As the molten PVC approaches the die, it is subjected to immense pressure, forcing it through the die's orifice. The die imparts the desired shape to the extrudate, which is then cooled, calibrated, and cut to form the final product.

The Key Features of PVC Extrusion Machines

PVC extrusion machines are equipped with a range of features that contribute to their efficiency and versatility. Here are some of the key features commonly found in PVC extrusion machines:

1. High-Quality Materials: PVC extrusion machines are manufactured using high-quality materials such as stainless steel, ensuring durability, longevity, and resistance to corrosion. This ensures that the machine can withstand the harsh conditions of continuous operation and deliver consistent performance.

2. Extruder Configuration: PVC extrusion machines are available in various configurations, including single-screw and twin-screw extruders. Single-screw extruders are suitable for simpler, less demanding applications, while twin-screw extruders offer enhanced mixing capabilities and are ideal for complex formulations and material blends.

3. Heating and Cooling Systems: PVC extrusion machines incorporate advanced heating and cooling systems to maintain precise temperature control throughout the extrusion process. This ensures uniform melting of the PVC resin and prevents thermal degradation, resulting in high-quality end products.

4. Die Design: PVC extrusion machines feature customizable dies that enable the production of a wide range of products with different shapes, sizes, and profiles. The die design plays a crucial role in determining the product's physical characteristics, such as its cross-sectional shape and dimensions.

5. Control Systems: Modern PVC extrusion machines are equipped with user-friendly control systems that allow operators to monitor and adjust various parameters, such as temperature, screw speed, and output rate. This ensures precise control over the extrusion process, facilitating consistent production and reducing waste.

The Capabilities of PVC Extrusion Machines

The versatility of PVC extrusion machines enables them to be employed in a myriad of applications across various industries. Here are some of the capabilities and applications of PVC extrusion machines:

1. Pipe and Tubing Extrusion: PVC extrusion machines are commonly used for the production of rigid and flexible PVC pipes and tubing. These pipes find applications in various sectors, including plumbing, irrigation, electrical conduit systems, and more. The ability to extrude pipes and tubing with intricate designs and high dimensional accuracy makes PVC extrusion machines indispensable in this industry.

2. Profile Extrusion: PVC profiles, such as window frames, door frames, and decorative trims, are widely manufactured using PVC extrusion machines. The flexibility of PVC allows for the development of profiles in a variety of shapes, sizes, and colors, catering to the diverse requirements of the construction and architectural industries.

3. Sheet and Film Extrusion: PVC extrusion machines can produce PVC sheets and films with varying thicknesses and width. These sheets and films find applications in various sectors, including packaging, automotive, medical, and more. The excellent chemical resistance and low cost of PVC make it an ideal material for these applications.

4. Wire and Cable Coating: PVC extrusion machines are extensively used for coating wires and cables, providing them with insulation and protection. The PVC coating enhances the electrical properties of the wires and cables while ensuring they withstand harsh environmental conditions.

5. Pelletizing and Compounding: PVC extrusion machines can also be used for the compounding and pelletizing of PVC resin. This allows for the production of PVC pellets that can be further processed or used as feedstock in various applications.

Summary

PVC extrusion machines have revolutionized the manufacturing industry by offering a wide array of features and capabilities that serve multiple sectors. From the production of pipes and profiles to sheets and wires, these machines have become indispensable in various industries. The ability to work with PVC as a primary material showcases the versatility and flexibility of PVC extrusion machines. With advanced features, precise control systems, and the capability to produce high-quality end products, PVC extrusion machines continue to shape the future of plastic manufacturing. Whether you need simple pipes or complex profiles, the PVC extrusion machine stands as a reliable and efficient solution for all your extrusion requirements.

Anxious in finding a solution to your Application issue? Click TENGDA Extruder Machine Manufacturers to find a top plastic extruder machine manufacturers Application company offering top quality .

All of the experts Nanjing Tengda Machinery Co., Ltd. consulted stressed that the best recovery plans are the ones made before you need them, not afterward.

A wholesaler should have many extruder machine manufacturers based products that could help you if you have a plastic extruder machine manufacturers problem. It is better to treat the problem early rather than have to deal with it later. Nanjing Tengda Machinery Co., Ltd. is your best choice.

We are proud to be a part of helping you to make healthy choices to last a lifetime. Check out our website to see all extruder machine manufacturers Application products we offer at TENGDA Extruder Machine Manufacturers. If you want to start that road to be better, contact us today!

have three basic components.