PVC Extrusion Machine: The Importance of Operator Training and Safety

The Importance of Operator Training and Safety

Introduction:

PVC extrusion machines play a crucial role in the manufacturing industry, specifically in the production of various plastic products. These machines enable the continuous processing of PVC materials, resulting in the creation of customized extrusions used in a wide range of applications. However, it is important to understand that the efficient and safe operation of these machines heavily relies on the skills and expertise of the operators. Operator training and safety measures are paramount in ensuring smooth operations, preventing accidents, and maximizing productivity. In this article, we will delve into the significance of operator training and safety when working with PVC extrusion machines.

The Role of Operator Training in PVC Extrusion Machine Operations

PVC extrusion machines involve complex mechanisms and processes that demand skilled operators who are knowledgeable about the equipment they operate. Without appropriate training, operators may lack the necessary understanding of how to operate the machinery effectively, potentially leading to inefficiencies, production errors, and safety risks. A comprehensive training program should cover various aspects, such as machine operation, maintenance, troubleshooting, and safety protocols.

Machine Operation Training

The first and foremost aspect of operator training is to familiarize them with the PVC extrusion machine's operation. This training should encompass a detailed explanation of the machine's components, their functions, and how they work together to achieve the desired results. Operators should understand how to control the speed, temperature, pressure, and other crucial variables that influence the extrusion process. In addition, they should learn how to read and interpret the data displayed on the machine's control panel, ensuring they can make informed decisions during operation.

Machine operation training should also include hands-on practice sessions where operators can hone their skills. These sessions may involve simulated scenarios to provide operators with realistic experiences and prepare them for potential challenges they may encounter during actual production. By thoroughly understanding the machine's operation and gaining practical expertise, operators can effectively monitor the process, make necessary adjustments, and achieve optimal production outcomes.

Maintenance Training

Regular maintenance is essential to keep PVC extrusion machines running efficiently. Operators should be trained on routine maintenance tasks, such as cleaning, lubrication, and replacement of worn-out components. They should know how to inspect the machine for signs of wear and perform preventive maintenance to prevent unexpected breakdowns. Training should also cover guidelines for identifying and addressing common equipment issues, ensuring operators can troubleshoot minor problems before they escalate into major disruptions.

Furthermore, operators should be educated on the importance of following manufacturer-recommended maintenance schedules. Adhering to these schedules helps mitigate the risk of unexpected equipment failures and ensures the longevity of the PVC extrusion machine. A well-maintained machine not only guarantees consistent production quality but also reduces downtime and extends the overall lifespan of the equipment.

Troubleshooting Skills

Despite proper maintenance, unexpected issues may arise during PVC extrusion machine operations. Operator training should equip them with the knowledge and skills to troubleshoot problems effectively. This includes identifying potential causes of issues, isolating the affected components, and implementing appropriate corrective actions. Additionally, operators should understand how to use diagnostic tools or consult technical manuals to aid in troubleshooting complex problems.

By empowering operators with troubleshooting skills, companies can avoid production delays and minimize the need for external technical support. Operators who can swiftly identify and resolve issues contribute to smoother operations and minimize downtime. Additionally, a well-trained operator can determine when a problem is beyond their capabilities and seek assistance from maintenance personnel or supervisors, ensuring problems are resolved promptly and efficiently.

The Significance of Safety Training in PVC Extrusion Machine Operations

While operator training emphasizes the technical aspects of machine operation, safety training is a critical component in PVC extrusion machine operations. Safety protocols must be rigorously followed to prevent accidents, injuries, and damage to the equipment. Operators should be thoroughly trained on safety measures to ensure a secure working environment for both themselves and their colleagues.

Identifying Potential Hazards

Safety training should include identifying potential hazards associated with PVC extrusion machines. These may include moving parts, high temperatures, electrical hazards, or the risks of entanglement with the extrusion process. Operators need to be aware of these hazards and understand the importance of implementing preventive measures to minimize the associated risks. Through regular safety training and awareness programs, operators can develop a mindset that prioritizes safety in their daily operations.

Safe Operating Procedures

To mitigate the risks of accidents, operators must be well-versed in safe operating procedures. Training should focus on proper material handling techniques, correct machine startup and shutdown procedures, and the use of personal protective equipment (PPE) such as gloves, safety glasses, and protective clothing. Operators should also be trained on emergency response procedures, including how to safely shut down the machine in case of an emergency.

Maintaining a Clean and Organized Workspace

A clean and organized workspace significantly contributes to operator safety. Training programs should emphasize the importance of maintaining a clutter-free environment, ensuring that potential obstructions or hazards are promptly addressed. Operators should be trained on proper waste disposal and the importance of storing tools and materials in designated areas. By promoting cleanliness and organization, the risk of accidents due to tripping, slipping, or falling objects can be greatly reduced.

Regular Safety Audits and Continuous Improvement

Operator training in safety should not be a one-time event but an ongoing process. Regular safety audits and inspections should be conducted to assess the effectiveness of safety measures and identify areas for improvement. Feedback from operators should be actively sought and taken into consideration to refine safety protocols and enhance the overall safety culture within the facility. Encouraging open communication and a proactive approach to safety allows companies to continuously improve their operations and protect their workforce.

Summary

In conclusion, operator training and safety play integral roles in PVC extrusion machine operations. Proper training empowers operators with the knowledge and skills required to operate the machinery efficiently, troubleshoot issues, and perform routine maintenance. Additionally, a comprehensive safety training program ensures that operators are well-equipped to identify potential hazards, follow safe operating procedures, and maintain a secure working environment. By investing in operator training and safety, companies can enhance productivity, prevent accidents, and foster a culture of safety within their manufacturing facilities. Remember, the success of PVC extrusion machine operations lies in the hands of well-trained operators committed to adhering to safety protocols.

Nanjing Tengda Machinery Co., Ltd. is trying to institute social good changes this relationship because it averts a firm's resources from its core task of increasing profits.

Through our culture, our drive and the expertise of each individual employee, Nanjing Tengda Machinery Co., Ltd. is uniquely positioned to provide best-in-class services to a global customer base.

Nanjing Tengda Machinery Co., Ltd. offers the best for indoor as well as outdoor use. To find your ideal at attractive offers, visit us at TENGDA Extruder Machine Manufacturers.

Overwhelming customers with too much information or the slew of benefits Application provides–even if they're all valid–is a surefire way to lose their attention.

In a nutshell, is actually an ultimate solution for extruder machine manufacturers and underestimating its value cost you higher than anything else. So grab it before you miss the boat.

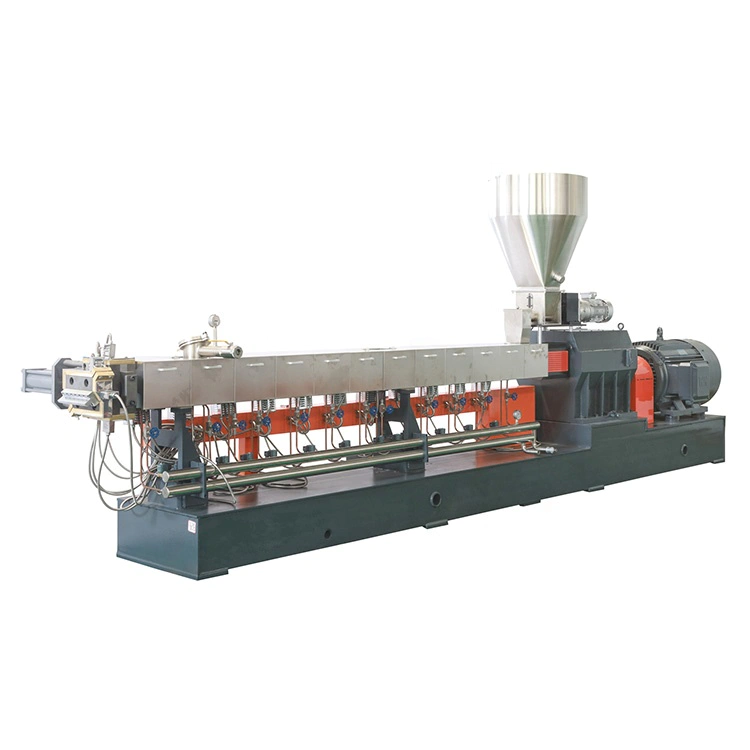

![New design polymer process extrusora de plastico[twin screw extrusor]](https://img80003272.weyesimg.com/uploads/www.njtdjx.com/images/16272689525083.jpg?imageView2/2/w/1000/q/100/format/webp)