PVC Pipe Extrusion Machine for Sale: Evaluating the Cost-Effectiveness of Your Investment

Introduction:

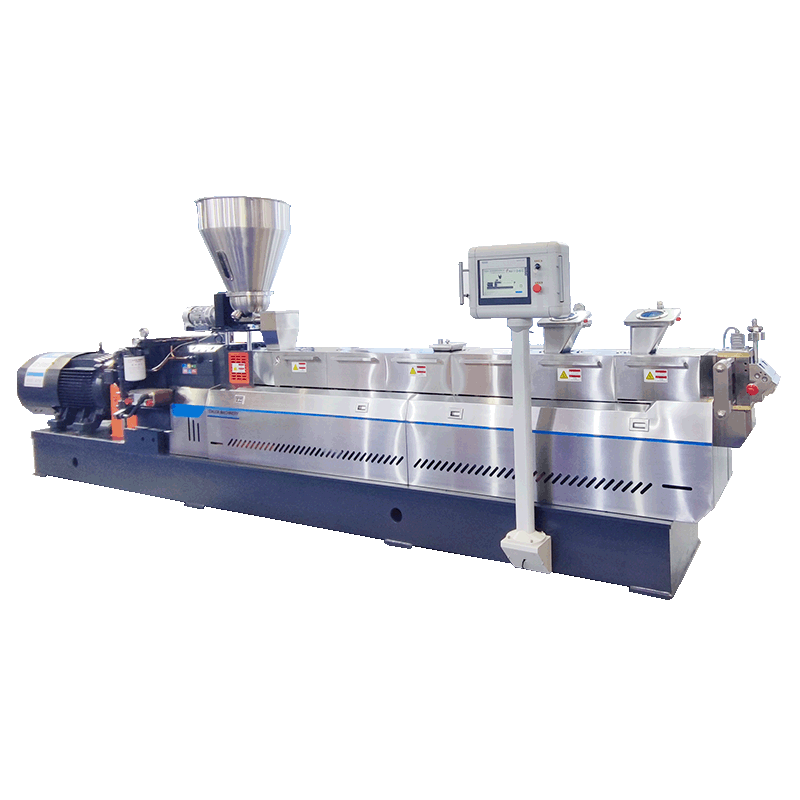

PVC pipe extrusion machines have become an essential part of the manufacturing industry. Known for their durability and versatility, PVC pipes are widely used in various applications such as plumbing, irrigation, and electrical conduits. As a result, the demand for high-quality PVC pipes continues to rise, making the investment in a PVC pipe extrusion machine a lucrative opportunity for manufacturers.

In this article, we will delve into the cost-effectiveness of investing in a PVC pipe extrusion machine. We will explore the various aspects that need to be considered before making this investment and examine how it can contribute to the long-term growth and profitability of your business.

The Importance of Quality:

Quality is a crucial aspect when it comes to PVC pipe production. Investing in a PVC pipe extrusion machine ensures that you can maintain full control over the quality of your pipes, from raw material selection to the final product. By producing high-quality PVC pipes consistently, you can build a reputation for reliability and durability in the market, leading to increased customer satisfaction and loyalty.

When evaluating the cost-effectiveness of a PVC pipe extrusion machine, it is essential to consider the long-term benefits of producing superior pipes. High-quality pipes are less prone to leaks, cracks, and failures, reducing the risk of costly repairs or replacements for customers. Moreover, the superior performance of these pipes can lead to a positive word-of-mouth reputation, attracting new customers and boosting sales.

Increased Efficiency and Productivity:

Investing in a PVC pipe extrusion machine can significantly enhance the efficiency and productivity of your manufacturing process. These machines are designed to streamline the pipe production process, minimizing human error and maximizing output. With automation features and advanced technologies, you can achieve higher production rates, reduce downtime, and ultimately increase profitability.

The extrusion process allows for continuous production, eliminating the need for manual cutting and joining of pipes. This results in a seamless and time-saving manufacturing process, enabling you to meet the growing demand for PVC pipes efficiently. By investing in a PVC pipe extrusion machine, you can decrease labor costs, optimize production schedules, and allocate your resources more effectively.

Cost Savings and Return on Investment:

While the initial investment in a PVC pipe extrusion machine may seem substantial, it is crucial to evaluate the long-term cost savings it can generate. By producing PVC pipes in-house, you can eliminate the need for outsourcing or purchasing pipes from third-party manufacturers, which often comes with added costs and lead times.

Additionally, a PVC pipe extrusion machine allows you to control the entire production process, including the selection of raw materials. By sourcing materials directly from suppliers, you can negotiate better prices, ensuring cost savings in the long run. Moreover, the flexibility of the extrusion process enables you to produce pipes of various sizes and specifications, catering to the diverse needs of your customers without incurring additional expenses.

Considering the cost savings and the potential increase in sales, investing in a PVC pipe extrusion machine can provide a significant return on investment. Depending on your production volume and market demand, the payback period for your initial investment can be relatively short, making it a financially viable option for business growth.

Maintenance and Operational Costs:

When evaluating the cost-effectiveness of your investment in a PVC pipe extrusion machine, it is essential to consider the maintenance and operational costs associated with the equipment. Proper maintenance is crucial for ensuring the longevity and optimal performance of your machine.

Regular maintenance activities include cleaning, lubrication, and component inspections to identify any signs of wear or damage. While performing these activities incur some costs, they are significantly lower compared to outsourcing pipe production or buying from wholesalers. Additionally, investing in preventive maintenance can help avoid costly breakdowns and extend the lifespan of your PVC pipe extrusion machine.

Operating costs, such as energy consumption, should also be considered when evaluating the cost-effectiveness of your investment. PVC pipe extrusion machines are designed to be energy-efficient, utilizing modern technologies to reduce power consumption. By choosing an energy-efficient machine and adopting sustainable production practices, you can further optimize your operational costs and minimize your environmental footprint.

Conclusion:

Investing in a PVC pipe extrusion machine offers numerous advantages, ranging from maintaining quality control and increasing productivity to achieving cost savings and a high return on investment. By producing high-quality PVC pipes in-house, you can establish a reputation for reliability, attract new customers, and enhance your bottom line.

When evaluating the cost-effectiveness of your investment, it is crucial to consider the long-term benefits, including the potential for increased sales, cost savings through eliminating outsourcing, and the ability to cater to various customer requirements. Additionally, by implementing a proactive maintenance strategy and choosing an energy-efficient machine, you can further enhance the cost-effectiveness of your investment.

In conclusion, a PVC pipe extrusion machine is not just an investment in your manufacturing process; it is an investment in the future success and sustainability of your business. With careful evaluation and consideration of the factors discussed in this article, you can make an informed decision and embark on a journey towards enhanced cost-effectiveness and profitability.