PVC Pipe Extrusion Machine for Sale: Factors to Consider Before Making a Purchase

Factors to Consider Before Making a Purchase

PVC pipe extrusion machines are invaluable equipment in the manufacturing industry. They are widely used for the production of various types of pipes with different diameters and thicknesses. If you are in the market for a PVC pipe extrusion machine, it is essential to consider several factors before making a purchase. These factors will not only help you choose the right machine but also ensure that it meets your specific production requirements and provides long-term value for your investment. In this article, we will explore the key factors you should consider before purchasing a PVC pipe extrusion machine.

Quality of the Machine Construction

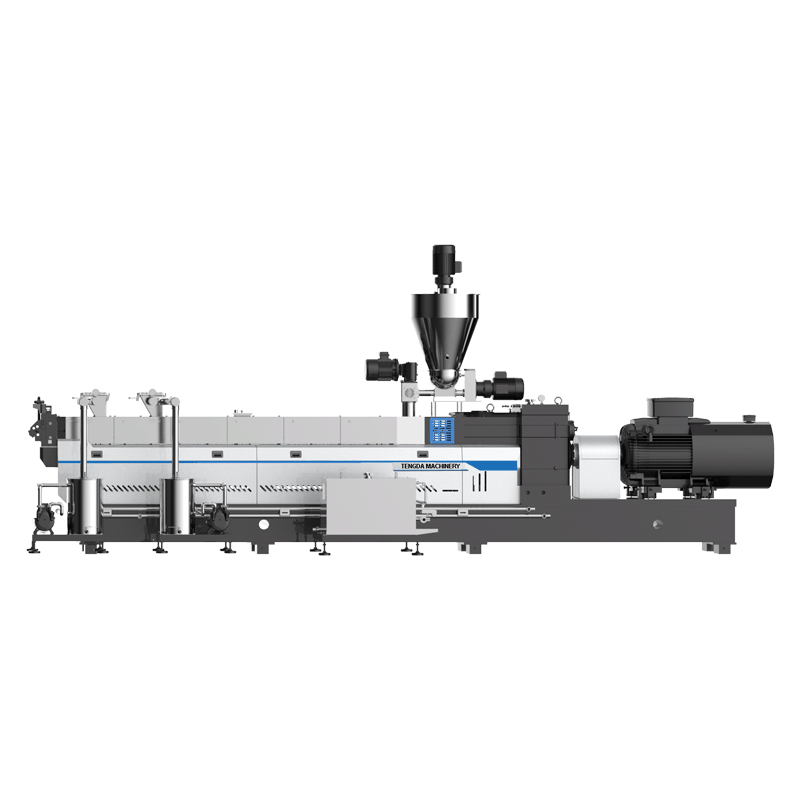

One of the foremost factors to consider before purchasing a PVC pipe extrusion machine is the quality of its construction. The machine should be built with high-quality materials and components that can withstand the demanding nature of the extrusion process. Look for a machine with a sturdy frame and robust components such as screws, barrels, and dies. These components should be made from high-grade materials that offer excellent resistance to wear and tear. Additionally, the machine's overall construction should be solid and well-engineered to provide stability, precision, and durability during the extrusion process.

Machine Capacity and Output

The capacity and output of the PVC pipe extrusion machine are crucial factors that should align with your production needs. Assess the desired output you require in terms of pipe diameter, length, and quantity. Consider the machine's production capacity in units per hour or kilograms per hour to ensure it can meet your production goals. It is equally important to examine the machine's flexibility to produce pipes of various sizes and configurations. This versatility will enable you to cater to diverse market demands and expand your production capabilities in the future.

Energy Efficiency

In an era where environmental sustainability is paramount, energy efficiency is a key consideration when purchasing a PVC pipe extrusion machine. Look for machines that are designed with energy-saving features such as variable frequency drives (VFDs) and efficient heating and cooling systems. These features can significantly reduce energy consumption and lower operational costs, making your production process more environmentally friendly and cost-effective in the long run. Additionally, energy-efficient machines usually have higher overall performance, resulting in increased productivity and improved product quality.

Technological Advancements

The manufacturing industry is constantly evolving, and PVC pipe extrusion machines are not exempt from technological advancements. Before making a purchase, it is essential to research the latest advancements and innovations in extrusion technology. Look for machines that incorporate cutting-edge features such as touchscreen control panels, advanced automation systems, and remote monitoring capabilities. These technological advancements can streamline your production process, improve efficiency, minimize downtime, and enhance the overall quality of your pipes. Choosing a machine with the latest technological features ensures that your investment remains relevant and competitive in the ever-changing market.

After-Sales Support and Service

When investing in a PVC pipe extrusion machine, it is crucial to consider the after-sales support and service provided by the manufacturer. Ensure that the manufacturer has a reputation for delivering excellent customer service and technical support. A reliable manufacturer should offer comprehensive training programs for operating and maintaining the machine, as well as quick and efficient troubleshooting assistance in case of any issues. Furthermore, inquire about the availability and cost of spare parts, as timely availability of parts can significantly reduce downtime and keep your production running smoothly. Investing in a machine from a manufacturer with excellent after-sales support ensures a seamless experience and long-term value.

In conclusion, purchasing a PVC pipe extrusion machine is a significant investment that requires careful consideration. By considering factors such as the quality of machine construction, capacity and output, energy efficiency, technological advancements, and after-sales support, you can make an informed decision and select a machine that is well-suited to your production requirements. Remember, choosing the right machine will not only enhance your production process but also contribute to the success and sustainability of your business in the long run.