Recycled Plastic Extruder: The Sustainable Solution to Plastic Waste

The Sustainable Solution to Plastic Waste

Plastic waste is one of the biggest environmental challenges of our time. With mountains of plastic piling up in landfills and polluting our oceans, finding sustainable solutions to tackle this issue has become a top priority. One innovative technology that shows great promise is the recycled plastic extruder. This cutting-edge machine has the ability to transform plastic waste into a valuable resource, reducing the need for virgin plastic production and minimizing environmental impact. In this article, we will explore the working principle of a recycled plastic extruder, its various applications, and the positive impact it can have on our planet.

What is a Recycled Plastic Extruder?

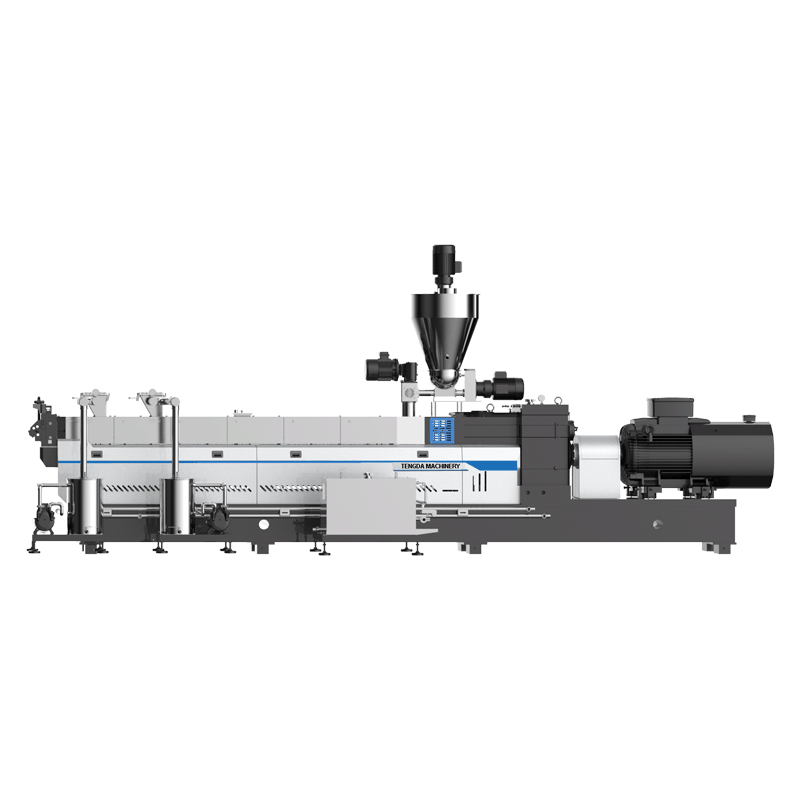

A recycled plastic extruder is a machine designed to process plastic waste and transform it into usable products. It operates on the principle of extrusion, which involves heating and molding plastic materials into a specific shape. The extruder works by feeding plastic waste, such as bottles or packaging materials, into a hopper. The waste is then heated and melted, forming a molten plastic that is forced through a die. The die shapes the plastic into a continuous profile, which can then be cooled and cut into the desired length.

The primary advantage of a recycled plastic extruder is its ability to give new life to plastic waste that would otherwise end up in landfills or oceans. By recycling and reusing plastic, we can significantly reduce the demand for virgin plastic production, conserving natural resources and decreasing pollution. Additionally, the extruder process can be customized to produce a wide range of plastic products, making it a versatile solution for various industries.

The Working Principle of a Recycled Plastic Extruder

To understand how a recycled plastic extruder works, let's delve into its working principle. The process begins with the collection of plastic waste, which can be sourced from various places such as recycling centers or municipal waste management facilities. The waste is sorted, cleaned, and shredded into small pieces to facilitate the extrusion process.

Once the waste is prepared, it is fed into the hopper of the extruder. Inside the machine, the plastic undergoes a series of steps to transform it into a usable form. Firstly, the waste is heated to a specific temperature, usually above the melting point of the plastic being processed. The melting process may involve a combination of heat sources, such as electric heaters or friction heat generated by the movement of the screws within the extruder.

As the plastic waste melts, it forms a molten mass that is then forced through a set of rotating screws within the extruder barrel. The screws act as a propeller, pushing the molten plastic forward and simultaneously mixing and homogenizing it. This helps to ensure a consistent melt and improve the quality of the final product.

Next, the molten plastic is forced through a specially designed die, which determines the shape and dimensions of the extruded product. The die creates a channel for the plastic to flow through, applying pressure to shape it into the desired form. The extruded plastic then undergoes a cooling process, which may involve water or air cooling, to solidify it and maintain its shape.

Once the plastic has cooled, it is cut into the desired length using a cutting device. The final product can be in various forms, such as rods, sheets, or even more complex profiles. These products can be further processed or used as-is, depending on their intended application.

Applications of Recycled Plastic Extruders

The versatility of recycled plastic extruders opens up a wide range of applications across various industries. Here are some of the key areas where these machines are making a significant impact:

1. Construction Industry: Recycled plastic extruders can be used to produce construction materials such as plastic lumber, which is a cost-effective and environmentally friendly alternative to traditional wood. Plastic lumber is durable, resistant to rot and insects, and can be used for a wide range of applications, including decking, fencing, and outdoor furniture.

2. Packaging Industry: Recycled plastic extruders play a crucial role in producing plastic packaging materials, such as sheets or films. These materials can be used for food packaging, blister packs, or protective wrapping, among other applications. By utilizing recycled plastic, manufacturers can reduce the environmental footprint of their packaging while maintaining product integrity.

3. Automotive Industry: Recycled plastic extruders enable the production of various automotive components, such as bumper beams, door panels, and interior trim. These components require high-strength materials, and recycled plastic can meet those requirements while minimizing the use of virgin plastics.

4. 3D Printing: The emerging field of 3D printing can greatly benefit from recycled plastic extruders. By using recycled plastic as a filament, 3D printing enthusiasts can create sustainable and customized products without relying solely on virgin plastic materials.

5. Household Products: Recycled plastic extruders can also be used to manufacture a wide range of household products, including pipes, window profiles, and furniture. These products offer the same functionality as their virgin plastic counterparts but with the added benefit of being environmentally friendly.

The Advantages of Recycled Plastic Extrusion

The use of recycled plastic extruders offers numerous advantages, both from an environmental and economic perspective. Let's take a closer look at some of these benefits:

1. Waste Reduction: As mentioned earlier, one of the most significant advantages of recycled plastic extrusion is the reduction in plastic waste sent to landfills or ending up in our oceans. By recycling plastic and converting it into valuable products, we can minimize the harmful impact of plastic waste on the environment.

2. Energy and Resource Conservation: Using recycled plastic requires much less energy compared to the production of virgin plastic. Additionally, the extraction of raw materials for virgin plastic production, such as crude oil, can be minimized, leading to conservation of natural resources.

3. Cost Savings: In several applications, recycled plastic extrusion can offer cost savings over traditional manufacturing processes. By using recycled plastic instead of virgin materials, manufacturers can reduce their production costs while still maintaining product quality and performance.

4. Versatility: Recycled plastic extruders can process various types of plastic waste, including different polymer types and colors. This versatility allows for the creation of a wide range of products with different specifications and properties.

5. Improved Corporate Image: Embracing sustainable practices, such as using recycled plastic, can enhance a company's reputation and attract environmentally-conscious customers. By demonstrating a commitment to reducing plastic waste, businesses can differentiate themselves in a crowded market and contribute to a cleaner, greener future.

The Future of Recycling with Recycled Plastic Extruders

As the world grapples with the plastic waste crisis, technologies like recycled plastic extruders offer a glimmer of hope for a more sustainable future. With their ability to transform plastic waste into valuable products, these machines are instrumental in closing the loop on plastic recycling. By investing in and promoting the use of recycled plastic extruders, we can move closer to a circular economy where waste is minimized, resources are conserved, and the environment is protected.

In conclusion, recycled plastic extruders present a sustainable solution to the pressing issue of plastic waste. By harnessing the power of this innovative technology, we can turn plastic waste into a valuable resource, reducing the demand for virgin plastic production and minimizing environmental harm. From construction materials to packaging and automotive components, the applications of recycled plastic extruders are diverse and promising. The time has come for governments, businesses, and individuals to embrace this technology and contribute to a cleaner, greener future.

If you have a plastic extruder machine manufacturers business, be sure to choose a from Nanjing Tengda Machinery Co., Ltd.. After all, you need quality equipment in order to provide your customers with quality service.

For more information please see our site at TENGDA Extruder Machine Manufacturers. Don't be hesitate to contact us!

The trend toward using extruder machine manufacturers Application to ease plastic extruder machine manufacturers, once established, soon extended into such additional fields as extruder machine manufacturers and plastic extruder machine manufacturers.

When you choose to buy instead of extruder machine manufacturers, the money you save may allow you to buy multiple other necessities, more than you had initially planned on buying.

Nanjing Tengda Machinery Co., Ltd. affords you a suitable low price for proving our ethical considerations.