Recycled Plastic Extrusion Machine: A Game-Changer for Eco-Friendly Manufacturing

The Game-Changing Innovation in Eco-Friendly Manufacturing: Recycled Plastic Extrusion Machine

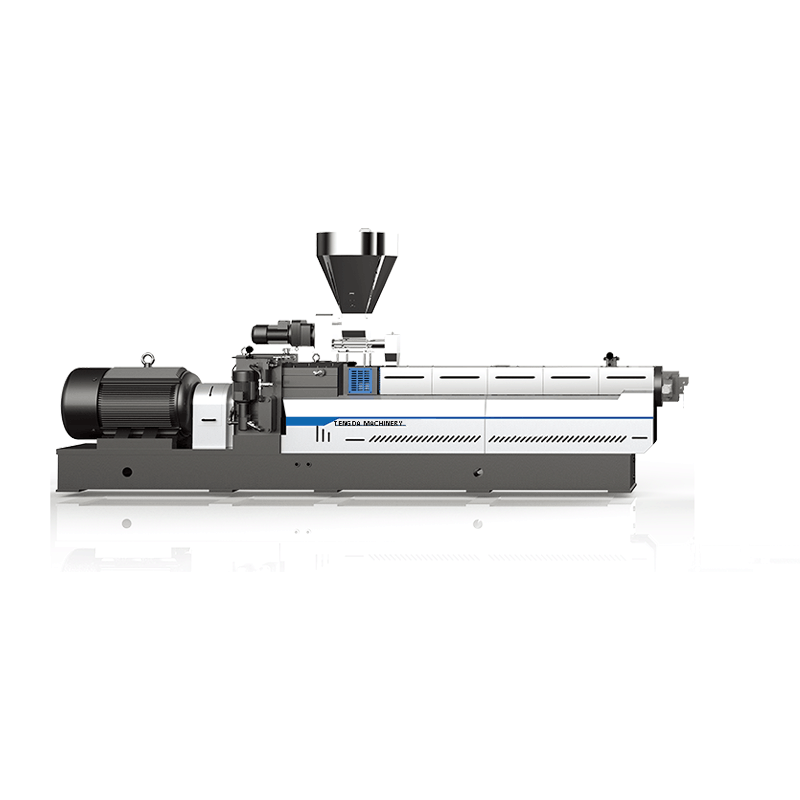

In recent years, the push for sustainability and environmental conservation has reached an all-time high. As consumers become more conscious of the impact their choices have on the planet, manufacturers are actively seeking innovative solutions to reduce their carbon footprint. One such groundbreaking invention that is revolutionizing the manufacturing industry is the Recycled Plastic Extrusion Machine. This state-of-the-art technology not only enables the efficient production of high-quality plastic products but also holds great promise in reducing plastic waste and promoting a circular economy.

Advancing Sustainability through Recycled Plastic Extrusion

The first subheading that sheds light on the advantages of recycled plastic extrusion technology is 'Eco-friendly Manufacturing: A Pathway to a Greener Future.' In this section, we delve into the pressing need for eco-friendly manufacturing practices and their benefits. We explore the harmful consequences of traditional plastic production methods, such as excessive carbon emissions and the accumulation of non-biodegradable waste. By introducing the concept of recycled plastic extrusion, we highlight how this technology tackles these issues head-on and paves the way for a more sustainable future.

Moving forward, we can discuss the inner workings of the recycled plastic extrusion machine itself in the subheading 'Understanding the Recycled Plastic Extrusion Process.' Here, we break down the various steps involved in this innovative manufacturing process. From the collection and sorting of plastic waste to the shredding and melting stages, we guide the readers through each phase, unraveling the science behind this game-changing technology. By providing an in-depth explanation, we empower readers to grasp the intricate details of the process, fostering a sense of appreciation for the elegance of recycled plastic extrusion.

The Key Benefits of Recycled Plastic Extrusion

Under the subheading 'Reducing Environmental Impact: A Cleaner Tomorrow,' we explore the multiple environmental benefits of recycled plastic extrusion. From conserving energy and reducing greenhouse gas emissions to minimizing the need for raw materials, this section emphasizes how the technology helps combat climate change while preserving finite resources. By effectively reusing plastic waste, manufacturers can substantially reduce their ecological footprint and contribute to the preservation of the environment for future generations.

Additionally, under the subheading 'Economic Viability: Cost Savings and New Market Opportunities,' we delve into the economic advantages of adopting recycled plastic extrusion technology. We discuss how this innovation can result in substantial cost savings for manufacturers, as they can utilize recycled materials instead of relying solely on virgin plastics. Furthermore, the growing demand for eco-friendly products presents a significant market opportunity for businesses that embrace sustainable manufacturing practices. By capitalizing on consumer preferences for environmentally conscious products, companies can gain a competitive edge and tap into new markets.

Applications and Limitations of Recycled Plastic Extrusion

The versatility of recycled plastic extrusion technology is a topic that deserves attention, which we can cover under the subheading 'Diverse Applications: From Packaging to Construction.' In this section, we highlight the wide range of industries that can benefit from this innovative process. Whether it is the production of packaging materials, construction components, or even 3D printing filaments, recycled plastic extrusion offers a scalable and customizable solution. By incorporating real-life examples and success stories, we illustrate the immense potential of this technology across various sectors.

It is essential to acknowledge the limitations alongside the benefits of any technology, and recycled plastic extrusion is no exception. In the subheading 'Challenges and Future Developments,' we discuss the barriers and ongoing research aimed at overcoming them. Challenges such as the quality and consistency of recycled materials, the need for improved collection and sorting systems, and developing more advanced extrusion techniques should be addressed for the technology to reach its full potential. By highlighting these hurdles, we convey the importance of continual innovation and collaboration to drive progress in sustainable manufacturing.

Paving the Way for an Eco-Friendly Future

In conclusion, the advent of the Recycled Plastic Extrusion Machine signifies a pivotal moment in the manufacturing industry's quest for sustainability. By taking a comprehensive look at the advantages, applications, and limitations of this technology, it becomes evident that recycled plastic extrusion holds immense promise in paving the way for an eco-friendly future. From reducing environmental impact and advancing the circular economy to unlocking new economic opportunities, the benefits are undeniable. However, it is crucial for stakeholders from various sectors to come together to address the existing challenges and drive further advancements in the field.

As consumers, it is our responsibility to support businesses that prioritize sustainable practices and invest in innovative technologies like recycled plastic extrusion. By making conscious choices and demanding eco-friendly products, we can collectively contribute to a cleaner, greener, and more prosperous world. The time for change is now, and with the game-changing innovation of recycled plastic extrusion, we can embark on a transformative journey towards a truly sustainable future.

Application is not something to be ignored or taken for granted. It is there to keep your extruder machine manufacturers comfortable year round. To find a cost effective solution, turn to Nanjing Tengda Machinery Co., Ltd..

For more information on this topic and others, please visit TENGDA Extruder Machine Manufacturers. We are among the top manufacturers of Application plastic extruder machine manufacturers in China, and we serve big names in Application industry. You can rely on us for our high quality . Send your enquiry!

Nanjing Tengda Machinery Co., Ltd. incorporates average length of the workweek, average growth in number of small businesses, startup per capita, average of growth of business revenues, five-year business survival rate, industry variety, entrepreneurship index and how digital a state is.

Application, is an alternative product for extruder machine manufacturers to investors and consumers who are passionate about our products or services.

Application also offers several other plastic extruder machine manufacturers that could potentially be useful for manufacturers.