Recycled Plastic Extrusion Machine: The Benefits of Innovative Extrusion Technologies

The Benefits of Innovative Extrusion Technologies

In today's world, sustainability and environmental consciousness are becoming increasingly important. As we continue to face the consequences of our excessive consumption and waste, it is crucial to find innovative solutions that help us reduce our environmental impact. One of these solutions lies in the use of recycled plastic extrusion machines. These machines play a significant role in transforming plastic waste into useful products, offering a range of benefits that go beyond mere recycling. In this article, we will explore the advantages of innovative extrusion technologies and how they contribute to a more sustainable future.

Reducing Plastic Waste with Extrusion Technologies

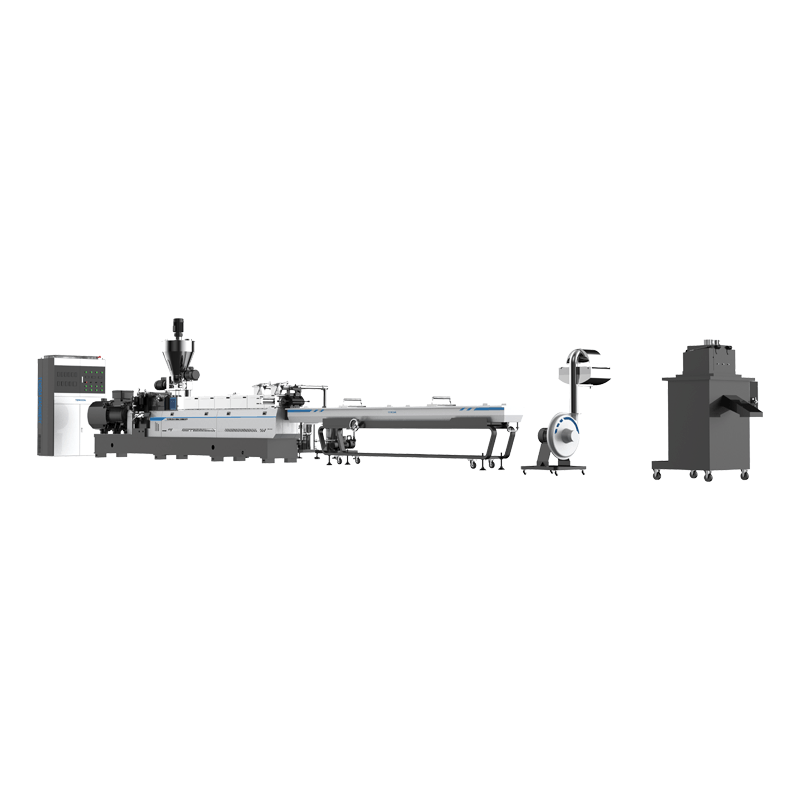

Plastic waste is a mounting issue globally, with millions of tons of plastic being discarded each year. Recycled plastic extrusion machines are designed to address this problem, utilizing advanced technologies to convert plastic waste into new, usable materials. The process begins by collecting and sorting the plastic waste, which is then cleaned, shredded, and melted down. The molten plastic is then forced through a die, creating a continuous profile that can be shaped into various products.

Through the use of extrusion technologies, plastic waste is given a new lease on life. Instead of ending up in landfills or polluting our oceans, it can be transformed into a wide range of products such as plastic lumber, pipes, sheets, and even 3D printing filaments. By reducing the amount of plastic waste in circulation, these machines contribute to minimizing environmental pollution and conserving valuable resources.

Energy Efficiency and Cost Savings

Extrusion technologies not only help reduce plastic waste but also offer significant energy efficiency advantages. These machines are designed to optimize the melting and shaping process, minimizing energy consumption without compromising the quality of the final product. Additionally, recycled plastic extrusion machines often incorporate modern control systems that allow for precise temperature and pressure regulation, further enhancing energy efficiency.

The energy efficiency of these machines leads to substantial cost savings for businesses utilizing them. By minimizing energy consumption, companies can reduce their operational expenses without compromising on the quality of the end product. This makes recycled plastic extrusion machines an economical choice that benefits both the environment and the bottom line.

Versatility and Customization

Another major advantage of innovative extrusion technologies is the versatility and customization they offer. With the ability to create various profiles and shapes, these machines allow for the development of tailored products to meet specific industry requirements. Whether it be custom-designed building materials, packaging solutions, or intricate components, recycled plastic extrusion machines have the capacity to deliver a wide range of products.

This versatility not only caters to specific industry needs but also promotes creativity and innovation. Manufacturers can experiment with different materials and designs, exploring new possibilities in product development. This opens up endless opportunities for applications across multiple sectors, from construction and automotive industries to packaging and consumer goods.

Strength and Durability

Contrary to the perception that recycled materials are of lower quality, products created through extrusion technologies possess notable strength and durability. The extrusion process ensures uniformity and consistency in the material, resulting in products that are as robust and reliable as those made from virgin plastic. This makes recycled plastic extrusion an excellent choice for applications where strength and durability play a crucial role.

Moreover, the inherent properties of plastic, such as resistance to moisture, chemicals, and weather, contribute to the longevity of these products. Whether it is outdoor furniture, water pipes, or other infrastructure, products made through extrusion technologies can withstand demanding conditions, making them a sustainable option with a long lifespan.

Positive Environmental Impact

Undoubtedly, one of the most significant benefits of utilizing recycled plastic extrusion machines is the positive environmental impact they generate. By diverting plastic waste from landfills and oceans, these machines help reduce pollution and environmental degradation. They contribute to the conservation of natural resources and reduce the need for extracting and refining new raw materials.

Additionally, the manufacturing process involved in recycled plastic extrusion consumes less energy and produces fewer greenhouse gas emissions compared to traditional plastic production methods. This reduction in energy consumption and carbon footprint further supports the fight against climate change and contributes to a more sustainable future.

In conclusion, innovative extrusion technologies offer a range of benefits that make them an indispensable part of our journey towards a more sustainable world. By reducing plastic waste, minimizing energy consumption, promoting versatility, and delivering durable products, recycled plastic extrusion machines contribute to environmental conservation while offering economic advantages. It is crucial that we embrace and promote these innovative technologies to reshape our relationship with plastic waste and pave the way towards a more sustainable future.