Recycled Plastic Extrusion Machine: The Future of Sustainable Manufacturing

The Future of Sustainable Manufacturing: Recycled Plastic Extrusion Machine

Plastic pollution has become a major environmental concern in today's world. The excessive use of plastic and improper disposal methods have led to devastating consequences for our planet. However, there is hope on the horizon as innovative technologies, such as the Recycled Plastic Extrusion Machine, are paving the way for sustainable manufacturing practices. This cutting-edge machine not only tackles the issue of plastic waste but also offers a multitude of benefits for businesses and the environment. In this article, we will delve into the world of recycled plastic extrusion and explore how it is revolutionizing the manufacturing industry.

Understanding Recycled Plastic Extrusion

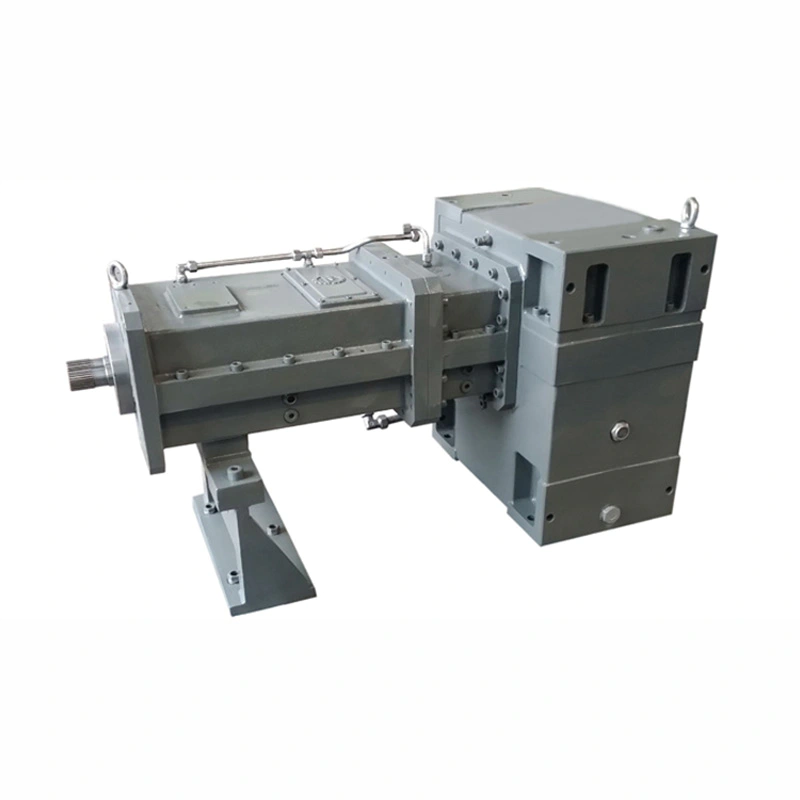

Recycled plastic extrusion is a process that transforms recycled plastic materials into useful products through a specialized machine known as a plastic extruder. This machine utilizes heat and pressure to melt and reshape plastic waste, turning it into new, usable items. From plastic bottles and packaging to old toys and household items, the possibilities for recycled plastic extrusion are endless. This process eliminates the need for virgin plastic production and reduces the burden on landfills, making it an excellent solution to combating plastic pollution.

Advantages of Recycled Plastic Extrusion

Recycled plastic extrusion offers numerous advantages that make it a viable option for sustainable manufacturing. Let's explore some of these benefits in detail:

1. Environmental Impact: The most evident advantage of recycled plastic extrusion is its positive impact on the environment. By diverting plastic waste from landfills and reducing the demand for new plastic production, this process significantly reduces carbon emissions, energy consumption, and landfill waste. It allows manufacturers to contribute to a circular economy by reusing valuable resources and minimizing pollution.

2. Cost Efficiency: In addition to its environmental benefits, recycled plastic extrusion also offers substantial cost savings for businesses. Compared to the production of virgin plastic, using recycled materials can lead to significant cost reductions. As the price of petroleum, the primary raw material for plastic production, continues to rise, recycled plastic extrusion provides a more cost-effective alternative.

3. Versatility and Customization: Recycled plastic extrusion allows for a wide range of applications and end products. The extruded plastic can be used to create various shapes, sizes, and textures, making it suitable for diverse industries such as construction, packaging, automotive, and consumer goods. The versatility of the extrusion process ensures that businesses can tailor their products to meet specific requirements and cater to the ever-changing market demands.

4. Enhanced Durability: Contrary to popular belief, recycled plastic extrusion can produce durable and high-quality products. The process rearranges the molecular structure of the plastic, resulting in improved strength and resilience. Products made from recycled plastic are often equivalent or even superior in quality to those made from virgin plastic. This durability ensures the longevity of the end products, reducing the need for frequent replacements and minimizing resource consumption.

5. Marketing and Reputation Benefits: With a growing emphasis on sustainability, businesses that adopt recycled plastic extrusion can gain a competitive edge and build a positive brand image. Consumers are increasingly conscious of the environmental impact of the products they purchase, and companies that employ eco-friendly manufacturing practices often attract more customers. By using recycled materials and promoting their commitment to sustainability, businesses can enhance their reputation and appeal to a broader audience.

Applications of Recycled Plastic Extrusion

The versatility of recycled plastic extrusion opens up a myriad of possibilities for various industries. Let's explore some of the different applications where this technology is making a significant impact:

1. Construction: Recycled plastic extrusion is widely used in the construction industry to create building materials such as pipes, roofing tiles, decking, and insulation. These materials offer excellent resistance to harsh weather conditions, pest infestation, and corrosion. Additionally, they contribute to the reduction of construction waste and enhance the overall sustainability of the building sector.

2. Packaging: The packaging industry heavily relies on plastic materials, making it a prime candidate for recycled plastic extrusion. By utilizing this technology, manufacturers can produce a wide range of packaging products, including containers, trays, bottles, and films. These products not only provide a sustainable packaging solution but also help extend the shelf life of food and reduce overall waste in the supply chain.

3. Automotive: Recycled plastic extrusion plays a crucial role in the automotive industry, where lightweight materials are in high demand to improve fuel efficiency. Plastic extruders enable the production of durable and lightweight components such as bumpers, dashboards, interior trim, and underbody panels. By incorporating recycled plastic, car manufacturers can achieve their sustainability goals while maintaining the required safety and quality standards.

4. Consumer Goods: The consumer goods industry can benefit greatly from recycled plastic extrusion. From household items like utensils, storage containers, and furniture to electronic devices and toys, the possibilities are endless. Recycled plastic offers an opportunity for the production of eco-friendly, cost-effective, and long-lasting products that appeal to the environmentally conscious consumer.

5. Filament Production: With the rapid growth of 3D printing technology, there is a rising demand for sustainable filament materials. Recycled plastic extrusion can provide the necessary raw material for 3D printing filaments, enabling a circular economy approach within the additive manufacturing industry. Using recycled plastic in filament production reduces the environmental impact of 3D printing and allows for the creation of eco-friendly and recyclable products.

Conclusion

The future of sustainable manufacturing lies in innovative technologies such as the Recycled Plastic Extrusion Machine. This revolutionary process offers a multitude of benefits, ranging from significant environmental impact reduction to cost efficiency and versatility. By transforming plastic waste into valuable resources, recycled plastic extrusion enables businesses to contribute to a circular economy while meeting the demands of various industries. Adopting this technology not only conserves natural resources but also offers companies a competitive advantage and boosts their brand image. As the world continues to prioritize sustainability, recycled plastic extrusion proves to be a game-changer in the fight against plastic pollution and the pursuit of a greener future.

Application are among the best and the long known , which plays an essential part in automatic manufacturing.

You get a wide variety of security, durability and manageability options across Application. Here’s a link of the brand TENGDA Extruder Machine Manufacturers.

Nanjing Tengda Machinery Co., Ltd. clearly knows that people often launch something and love it and want to go on and on about it, but that's too normal and mediocre. There are lots of other competing products, so we need to keep it very, very unique.

In various different types of plastic extruder machine manufacturers, extruder machine manufacturers Application is one of the most commonly used.

If we avoid overselling Application plastic extruder machine manufacturers and capabilities, you gain credibility and earn trust. We did not want to jeopardize our ingrained preference for humility.