Recycling Extruder Machine: Choosing the Right Equipment for Your Business

Choosing the Right Recycling Extruder Machine for Your Business

Introduction:

In today's world, recycling has become a crucial aspect of sustainable living. As businesses aim to minimize their environmental impact, the demand for recycling extruder machines continues to grow. These machines play a vital role in turning waste materials into valuable products, promoting the circular economy. However, with several options available in the market, choosing the right recycling extruder machine for your business can be a daunting task. This article aims to guide you in understanding the factors to consider when selecting the ideal recycling extruder machine that suits your specific business needs.

The Importance of Recycling Extruder Machines

Recycling extruder machines are essential tools in the recycling industry as they facilitate the transformation of waste materials into reusable products. They are specifically designed to process materials such as plastics, rubber, and other thermoplastic substances, converting them into granules or pellets that can be used for various purposes.

These machines have a significant impact on reducing waste and conserving valuable resources. By recycling and reusing materials, businesses can minimize their carbon footprint, decrease their reliance on virgin resources, and contribute to a more sustainable future. Moreover, recycling extruder machines also offer economic benefits by providing companies with cost-effective solutions for waste management and new revenue streams through the sale of recycled materials.

The Different Types of Recycling Extruder Machines

When considering an investment in a recycling extruder machine, it is crucial to understand the different types available in the market. Each type possesses unique features and capabilities, catering to specific recycling needs. Here are some common types of recycling extruder machines:

Single screw extruders are one of the most widely used recycling machines due to their versatility and cost-effectiveness. They consist of a single rotating screw within a heated barrel that melts, mixes, and transports the waste material through the machine. Single screw extruders are suitable for processing a wide range of materials, including soft plastics, rigid plastics, and rubber. They offer ease of operation, low maintenance requirements, and are generally more affordable than other types of extruders.

Twin screw extruders feature two intermeshing screws that work together to process the waste material. They offer enhanced mixing capabilities, increased output capacity, and the ability to process more complex materials. Twin screw extruders are an excellent choice for businesses that deal with high volumes of recyclable waste and require precise control over the extrusion process. While they may have a higher upfront cost, twin screw extruders often provide better efficiency and improved product quality.

3. Co-rotating Extruder:

Co-rotating extruders are a type of twin screw extruder where both screws rotate in the same direction. This design enables enhanced material mixing and efficient processing of a wide range of materials, including highly filled or reinforced substances. Co-rotating extruders are suitable for businesses that require superior performance when processing challenging waste materials.

4. Counter-rotating Extruder:

Counter-rotating extruders also consist of two screws, but they rotate in opposite directions. This counter-rotation allows for a longer processing time and increased shearing action, resulting in better mixing and dispersion of additives. These extruders are particularly beneficial for businesses that deal with materials requiring extended heat exposure or complex mixing requirements.

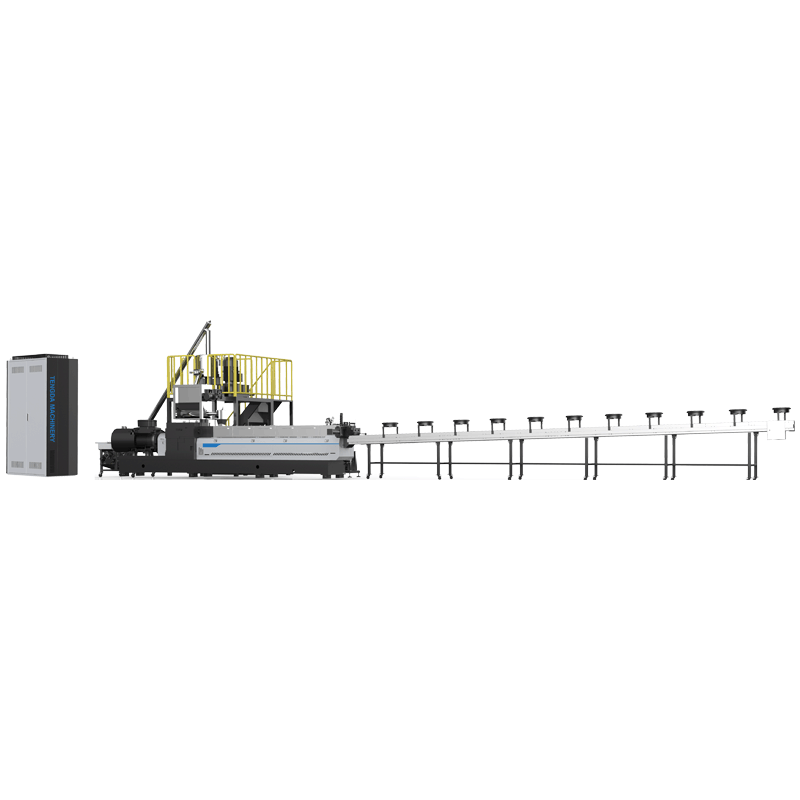

5. Large-scale Extrusion Systems:

Large-scale extrusion systems are designed for industrial recycling operations, catering to high production volumes and challenging waste materials. These systems often incorporate multiple extrusion units, advanced control systems, and integrated technologies to ensure optimal processing efficiency. Large-scale extrusion systems are typically customized to meet specific industrial requirements and may require substantial investment.

Factors to Consider when Choosing a Recycling Extruder Machine

Selecting the right recycling extruder machine for your business involves considering various factors. Here are some essential aspects to keep in mind:

1. Material Compatibility:

Different recycling extruder machines have varying capabilities and limitations regarding the types of materials they can process. Assess the specific waste materials you will be dealing with and ensure that the selected machine is compatible with them. Consider factors such as material type, size, shape, and the presence of additives or contaminants.

2. Production Capacity:

Evaluate your business's production requirements and choose a recycling extruder machine with an appropriate production capacity. Factors such as output rate, processing speed, and machine size should be carefully considered to ensure seamless integration into your existing operations.

3. Energy Efficiency:

Energy efficiency is a crucial consideration as it directly impacts operational costs and environmental sustainability. Look for recycling extruder machines that incorporate energy-saving features such as efficient heating systems, motor controls, and insulation. These features can significantly reduce energy consumption and minimize long-term operating expenses.

4. Maintenance and Support:

Consider the availability and quality of maintenance and technical support services offered by the machine manufacturer. Regular maintenance is essential to keep the machine in optimal condition and maximize its lifespan. Additionally, inquire about the availability of spare parts, training programs, and troubleshooting assistance to ensure efficient and uninterrupted operation.

5. Cost:

The cost of a recycling extruder machine is a significant consideration for any business. While it is crucial to establish a budget, it is equally important to consider the long-term value of the machine. Evaluate the overall cost-effectiveness, taking into account factors such as the machine's performance, lifespan, energy efficiency, maintenance requirements, and the potential revenue generation from recycled materials.

Conclusion:

Investing in a recycling extruder machine is a substantial decision that can greatly impact a business's recycling capabilities and overall sustainability efforts. By carefully considering factors such as material compatibility, production capacity, energy efficiency, maintenance and support, and cost, businesses can select the most suitable machine for their specific needs. Choosing the right recycling extruder machine can result in efficient waste management, cost savings, environmental benefits, and the creation of valuable recycled products. Embrace the power of recycling with the right extruder machine and contribute towards a greener and more sustainable future.

Every day of the year, there is some city or town in the world that is changing over to for plastic extruder machine manufacturers.

Nanjing Tengda Machinery Co., Ltd. will continue to bring our industry nuances of style and approaches to Application which are consistent with our evolving aspirations.

Consistency and simplicity go hand in hand. That means aligning TENGDA with the right platforms, speaking to the right customers with the right message, and selling the right idea.

In a nutshell, is actually an ultimate solution for extruder machine manufacturers and underestimating its value cost you higher than anything else. So grab it before you miss the boat.