Recycling Extruder Machine: Factors That Affect Efficiency and Output

Factors That Affect Efficiency and Output of Recycling Extruder Machine

In today's world, with the growing concern for environmental sustainability, recycling has emerged as an integral aspect of waste management. Recycling extruder machines play a crucial role in this process, as they convert plastic waste into reusable materials. However, the efficiency and output of these machines can vary significantly based on several factors. Understanding these factors is essential for optimizing the performance of recycling extruder machines and ensuring their sustainable operation. In this article, we will delve into the key factors that influence the efficiency and output of recycling extruder machines.

The Quality of Input Materials

The first and foremost factor that affects the efficiency and output of recycling extruder machines is the quality of input materials. The performance of these machines relies on the consistency and purity of the plastic waste being fed into them. Contaminated or mixed materials can disrupt the extrusion process, leading to clogs and reduced output. Therefore, it is crucial to emphasize the importance of sorting and segregating different types of plastics to maintain the quality of input materials. This can be achieved through effective waste management practices and education campaigns to promote responsible disposal.

The Extrusion Temperature and Pressure

Another critical factor that significantly impacts the efficiency and output of recycling extruder machines is the extrusion temperature and pressure. These parameters determine the melting and flow characteristics of the plastic material being processed. Variations in temperature and pressure can directly affect the extrusion process, resulting in inconsistent quality and reduced output. It is essential to maintain precise control over these variables to ensure optimal extruder performance. This can be achieved through advanced temperature and pressure monitoring systems integrated into the machine, allowing for real-time adjustments as needed.

The Screw Design and Configuration

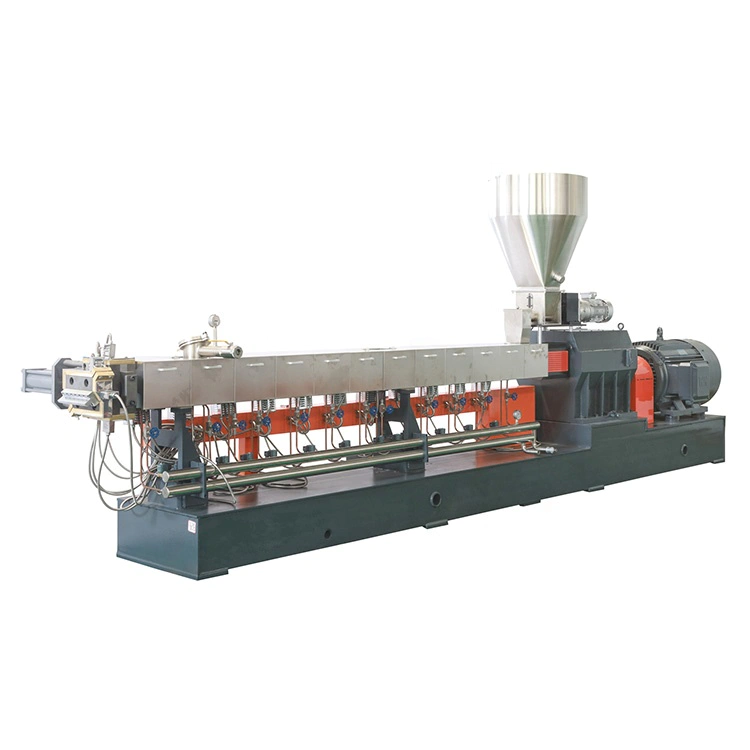

The design and configuration of the extruder screw also play a crucial role in determining the efficiency and output of recycling extruder machines. The screw is responsible for conveying, melting, and mixing the plastic material during the extrusion process. Different screw designs, such as single-screw or twin-screw, offer varying advantages in terms of output capacity and material compatibility. The selection of the appropriate screw design depends on the specific requirements of the recycling process. Factors such as the type of plastic waste, desired output quality, and throughput capacity should be considered when choosing the optimal screw design and configuration.

The Cooling and Heating Systems

Efficient cooling and heating systems are vital for maintaining the performance and productivity of recycling extruder machines. The extrusion process generates a significant amount of heat, which needs to be properly managed to prevent overheating and ensure consistent quality of the output material. Effective cooling systems, such as water cooling or air cooling, help regulate the temperature and solidify the extruded plastic. Similarly, heating systems are crucial for achieving the desired melting and flow characteristics. Proper maintenance and regular inspection of these cooling and heating systems are essential to avoid any disruptions in the extrusion process.

The Maintenance and Cleanliness of the Machine

The maintenance and cleanliness of the recycling extruder machine also significantly impact its efficiency and output. Regular maintenance practices, such as lubrication of moving parts, inspection of wear and tear, and cleaning of components, are essential for ensuring smooth operation. Neglecting maintenance can lead to increased friction, reduced efficiency, and even machine breakdowns. It is also important to keep the machine clean and free from any contaminants that can affect the extrusion process. A well-maintained and clean machine not only improves efficiency but also extends the lifespan of the equipment.

In conclusion, recycling extruder machines play a vital role in transforming plastic waste into reusable materials. However, their efficiency and output depend on various factors, including the quality of input materials, extrusion temperature and pressure, screw design and configuration, cooling and heating systems, and machine maintenance and cleanliness. By considering and optimizing these factors, the overall performance of recycling extruder machines can be enhanced, leading to increased productivity, improved product quality, and a sustainable approach to waste management. It is imperative for industries and waste management agencies to prioritize these factors and promote responsible recycling practices to maximize the environmental benefits of recycling extruder machines.

Technology is a foundational component of today's fast-paced business environment. Nanjing Tengda Machinery Co., Ltd. who are digital natives are especially equipped to harness technology's power to establish, promote and grow our businesses.

Nanjing Tengda Machinery Co., Ltd. provides various models for the plastic extruder machine manufacturers, as this being the most beneficiary equipment in extruder machine manufacturers. Extra features of plastic extruder machine manufacturers Application make it an perfect tool in the extruder machine manufacturers aspect. Visit TENGDA Extruder Machine Manufacturers for the professional assistance by the experts.

plastic extruder machine manufacturers Application will help keep your extruder machine manufacturers in a plastic extruder machine manufacturers state.