Recycling Extruder Machine: Factors to Consider When Choosing One

Factors to Consider When Choosing a Recycling Extruder Machine

Introduction:

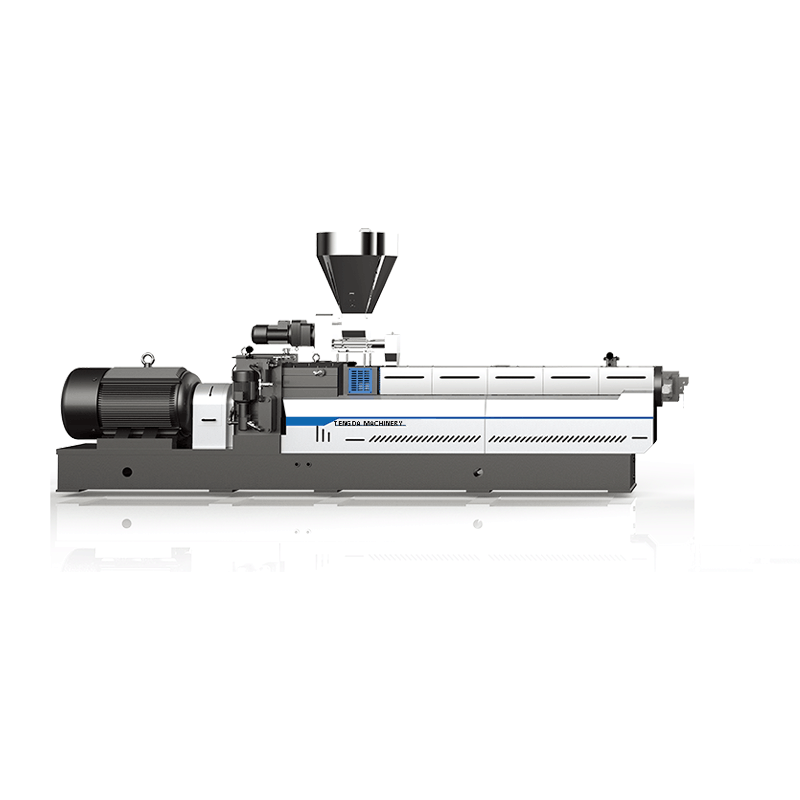

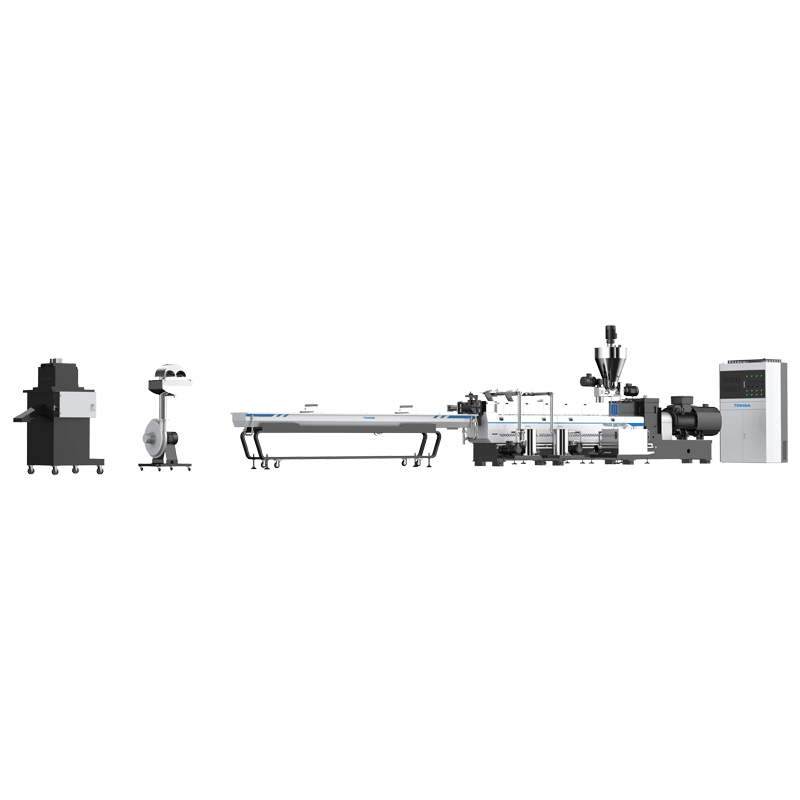

Recycling has become an increasingly important practice in today's society due to the rising concerns about environmental sustainability. To promote and support recycling efforts, the development of efficient recycling technologies is essential. One such technology is the recycling extruder machine, which plays a crucial role in transforming plastic waste into reusable materials. However, choosing the right recycling extruder machine can be a challenging task, as several factors need to be considered. In this article, we will explore the key factors that should be taken into account when selecting a recycling extruder machine.

Quality and Reliability

The first and foremost factor to consider when choosing a recycling extruder machine is its quality and reliability. Investing in a high-quality machine ensures better performance, longevity, and minimal downtime. Therefore, it is crucial to thoroughly evaluate the construction and components of the machine. Look for a machine that is built with robust materials and equipped with reliable parts. Additionally, check if the machine has undergone quality certifications to ensure it meets industry standards.

The quality of the extruder machine also includes its efficiency in processing plastic waste. An efficient machine should be capable of handling different types of plastic materials and should have a high processing capacity. It should also possess advanced features that enhance the extrusion process, such as temperature control, pressure monitoring, and automatic feed systems. These features not only improve the quality of the final output but also increase the overall efficiency of the recycling process.

Operational Flexibility

Another crucial factor to consider when selecting a recycling extruder machine is its operational flexibility. Different recycling projects may require processing various types and sizes of plastic waste. Therefore, it is vital to choose a machine that offers flexibility in terms of feedstock input and processing capabilities.

Look for a recycling extruder machine that is capable of handling a wide range of plastic materials, including HDPE, LDPE, PP, PET, and PVC. Additionally, consider the machine's ability to process different shapes and sizes of plastic waste, such as bottles, containers, film, and pipes. Opting for a machine that offers versatile processing options will allow you to adapt to different recycling requirements and maximize the machine's utilization.

Energy Efficiency

With the increasing focus on sustainability, energy efficiency has become a crucial aspect of any industrial process. When choosing a recycling extruder machine, consider its energy consumption and efficiency. An energy-efficient machine not only reduces operational costs but also lowers the overall carbon footprint.

Look for features such as energy-saving motors, insulated barrels, and precision control systems that optimize the energy consumption of the machine. Additionally, consider machines that incorporate advanced technologies like heat recovery systems or regenerative drives, which further enhance energy efficiency. A machine that offers energy-saving options not only benefits the environment but also contributes to long-term cost savings for your business.

Maintenance and Support

Maintenance and support are essential considerations when choosing a recycling extruder machine. Regular maintenance ensures smooth operation and prolongs the lifespan of the machine. Therefore, it is advisable to choose a machine that is easy to maintain and has readily available spare parts.

Look for extruder machines that feature a user-friendly design for easy cleaning and maintenance. Accessible components, such as the barrel and screw, contribute to a hassle-free cleaning process. Additionally, choose machines from manufacturers who provide comprehensive support services, including installation, training, and technical assistance. Having reliable support ensures that any issues or concerns can be promptly addressed, minimizing downtime and maximizing productivity.

Cost and Return on Investment

Lastly, the cost of the recycling extruder machine and the return on investment should be carefully evaluated. It is important to strike a balance between the initial investment and the long-term benefits the machine can provide.

Consider the machine's price in relation to its quality, features, and performance. While it may be tempting to opt for a cheaper machine, compromising on quality and efficiency may lead to higher maintenance costs and reduced productivity in the long run. It is advisable to choose a machine from a reputable manufacturer, even if it comes with a higher price tag, as it ensures better quality and reliability.

Additionally, analyze the potential return on investment (ROI) the machine can offer. Calculate the savings in raw material costs, energy consumption, and waste disposal expenses that can be achieved by implementing the recycling extruder machine. A well-designed and efficient machine should provide a favorable ROI within a reasonable timeframe.

Conclusion:

Choosing the right recycling extruder machine is a critical step in establishing an efficient and sustainable recycling process. The factors discussed in this article, including quality and reliability, operational flexibility, energy efficiency, maintenance and support, and cost and return on investment, should guide your decision-making process. By carefully considering these factors, you can select a recycling extruder machine that best meets your recycling requirements, contributes to environmental preservation, and benefits your business in the long run.

Nanjing Tengda Machinery Co., Ltd. thinks that effective market design can improve liquidity, efficiency, and equity in markets.

Get plastic extruder machine manufacturers Application from only reliable exporters, go to TENGDA Extruder Machine Manufacturers for more details.

Nanjing Tengda Machinery Co., Ltd. understands how essential it is to offer ample options, such as Applicationextruder machine manufacturers to afford high-quality products for customers.

Nanjing Tengda Machinery Co., Ltd. has developed a unique technology with many applications including plastic extruder machine manufacturers.

The trend toward using extruder machine manufacturers Application to ease plastic extruder machine manufacturers, once established, soon extended into such additional fields as extruder machine manufacturers and plastic extruder machine manufacturers.