Selecting the Right PVC Sheet Extrusion Machine for Your Manufacturing Operations

Selecting the Right PVC Sheet Extrusion Machine for Your Manufacturing Operations

Introduction

In today's competitive manufacturing industry, having the right machinery and equipment is crucial for ensuring efficient and high-quality production. When it comes to manufacturing PVC sheets, selecting the appropriate extrusion machine is of utmost importance. This article aims to guide you through the process of choosing the right PVC sheet extrusion machine for your specific manufacturing operations. From understanding the basics to considering essential factors, we provide you with valuable insights to make an informed decision.

Understanding PVC Sheet Extrusion

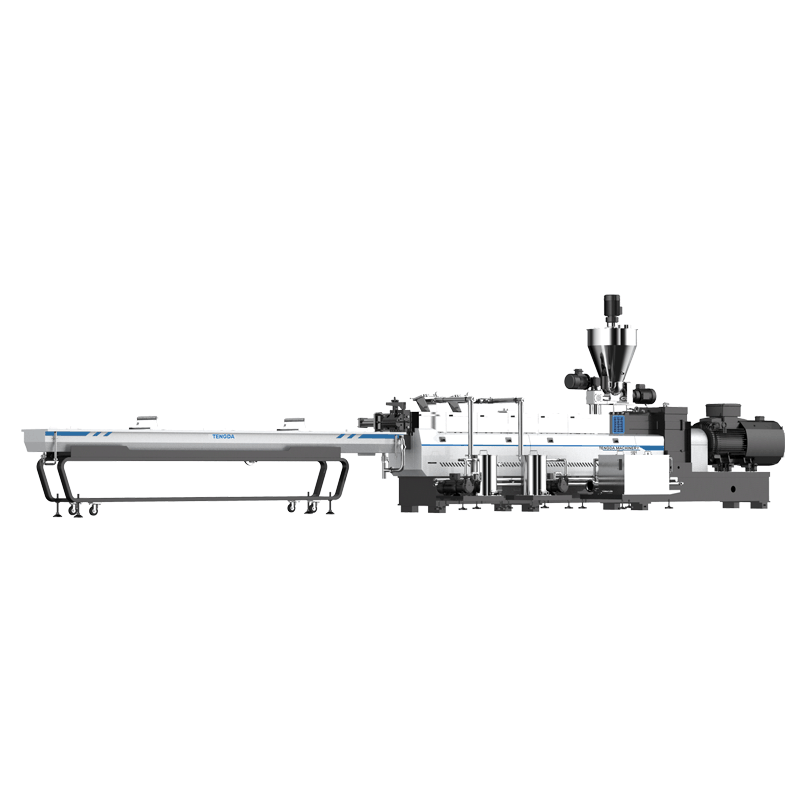

PVC (Polyvinyl Chloride) sheet extrusion involves the process of melting PVC resin pellets and then transforming the molten material into a continuous sheet form. PVC sheets are widely used in various industries, including construction, automotive, packaging, and more. The extrusion process utilizes an extruder machine consisting of several key components, such as a hopper, screw, barrel, and die. These components work together to melt, mix, and shape the PVC material into a sheet.

Types of PVC Sheet Extrusion Machines

There are various types of PVC sheet extrusion machines available in the market, each designed for specific manufacturing requirements. Understanding these types will help you choose the right machine for your operations:

1. Single Screw Extruder: This is the most common type of extruder used for PVC sheet production. It features a single rotating screw within a heated barrel. Single screw extruders are versatile, cost-effective, and suitable for a wide range of PVC sheet applications.

2. Twin Screw Extruder: As the name suggests, twin screw extruders have two intermeshing screws instead of just one. They offer enhanced mixing capabilities, higher output rates, and better control over the extrusion process. Twin screw extruders are ideal for PVC sheet production requiring specific material properties or additives.

Key Considerations for Choosing a PVC Sheet Extrusion Machine

Selecting the right PVC sheet extrusion machine involves considering several important factors. Here are some key points to keep in mind:

1. Production Capacity: Determine your required production capacity in terms of the amount of PVC sheet you need to manufacture per unit of time. This will help you choose a machine with the appropriate screw diameter, barrel length, and extrusion speed.

2. Sheet Thickness and Width: Identify the desired thickness and width of the PVC sheet you intend to produce. Different extruders have varying capabilities when it comes to sheet dimensions. Ensure that the machine you choose can meet your specific requirements.

3. Material Compatibility: Consider the type and formulation of PVC resin you will be using. Some extruders are better suited for processing PVC compounds with specific additives or fillers. Ensure that the machine is compatible with the material you will be working with.

4. Energy Efficiency: Look for energy-efficient extrusion machines equipped with modern technologies, such as frequency inverters or high-performance heating elements. Opting for an energy-efficient machine will not only reduce your operational costs but also contribute to a greener production process.

Additional Features and Considerations

Apart from the basic requirements mentioned above, here are some additional features and considerations to think about when selecting a PVC sheet extrusion machine:

1. Cooling and Calibrating Systems: High-quality cooling and calibrating systems are essential for ensuring uniform sheet thickness and preventing warping or distortion. Look for machines with effective cooling methods like air or water baths, as well as adjustable calibrating mechanisms.

2. Automatic Control and Monitoring: Consider machines that offer advanced control systems with user-friendly interfaces. Automatic systems for temperature control, pressure monitoring, and sheet thickness measurement can greatly improve efficiency and product consistency.

3. Ease of Maintenance: Look for machines that are easy to clean, maintain, and repair. A machine with readily accessible parts, easy die changes, and efficient cleaning mechanisms will help minimize downtime and improve overall productivity.

Conclusion

Selecting the right PVC sheet extrusion machine for your manufacturing operations is crucial for achieving optimal production efficiency and product quality. By understanding the different types of extruders, considering key factors, and evaluating additional features, you can make an informed decision. Remember to prioritize your specific requirements, such as production capacity, sheet dimensions, and material compatibility. Investing in the right PVC sheet extrusion machine will undoubtedly contribute to the success and competitiveness of your manufacturing business.

When you find yourself in need of Application extruder machine manufacturers, you may not know where to begin. And that's OK! Search out Nanjing Tengda Machinery Co., Ltd. to handle your Application needs.

Want to learn more about plastic extruder machine manufacturers Application? Check out TENGDA Extruder Machine Manufacturers.

We utilize our expertise to develop services that add value at each phase of theApplication development cycle. We evaluate and implement new strategies in response to changing customer profiles and market conditions.

TENGDA focuses on three key elements—process, people, and technology—the authors found that people of two seemingly opposite cultures are able to work together in a project-based environment to complement each other and reap mutual benefits for a win-win result.