Sheet Extrusion Machine: Essential Features and Functions for Efficient Production

Sheet Extrusion Machine: Essential Features and Functions for Efficient Production

Introduction

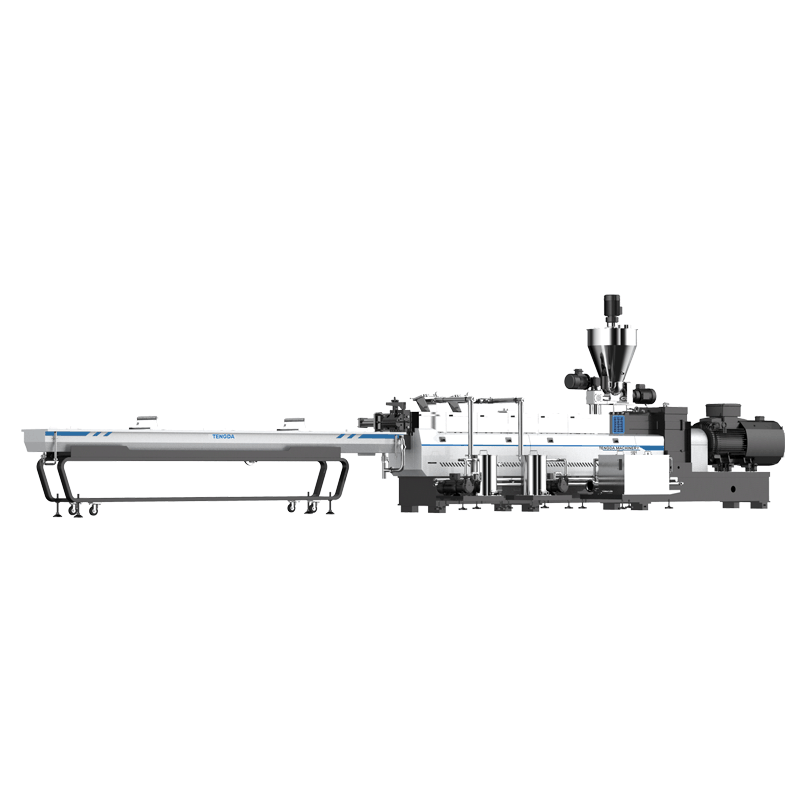

The sheet extrusion machine is a crucial piece of equipment in the plastic manufacturing industry. It is responsible for producing high-quality plastic sheets of various sizes and thicknesses. This article will explore the essential features and functions of a sheet extrusion machine, highlighting its importance in achieving efficient production processes.

1. Understanding Sheet Extrusion Machine

Sheet extrusion is a manufacturing process that involves feeding plastic resin into a heated barrel, where it is melted and conveyed through a specialized die. The molten plastic is then rapidly cooled to form a flat sheet of plastic with uniform thickness and width. The sheet extrusion machine consists of several key components that facilitate this process.

a) Extruder Unit

The extruder unit is the heart of the sheet extrusion machine. It comprises a screw, barrel, and motor assembly that work together to melt the plastic resin. The screw rotates within the barrel, applying heat and pressure to melt the plastic pellets. The speed and temperature of the extruder can be adjusted to achieve precise control over the extrusion process.

b) Die Assembly

The die assembly is responsible for shaping the molten plastic into a flat sheet. It consists of a metal plate with a carefully designed opening, which determines the width and thickness of the sheet. The die assembly is positioned immediately after the extruder, where the molten plastic flows through and takes the desired shape.

c) Cooling System

After passing through the die, the molten plastic sheet needs to be rapidly cooled to maintain its shape and properties. A cooling system, typically comprising of water or air, is used to cool the sheet to the required temperature. This ensures that the sheet solidifies properly and retains its dimensional stability.

d) Take-off Unit

The take-off unit is responsible for pulling the newly formed sheet away from the die and transporting it along the production line. It utilizes a series of driven rollers or belts to control the speed and tension of the sheet. The take-off unit ensures consistent and smooth pulling of the sheet, preventing any distortions or unevenness.

e) Winding System

The winding system is the final stage of the sheet extrusion process. It involves carefully winding the sheet onto a rotating mandrel or roller to create a usable roll of plastic sheet. The winding system ensures that the sheet is evenly wound without any wrinkles or creases, facilitating easy storage, handling, and transportation.

2. Features of an Efficient Sheet Extrusion Machine

To achieve efficient production and maintain consistent product quality, modern sheet extrusion machines offer several key features. These features enhance productivity, flexibility, and ease of operation, making the process more robust and reliable.

a) PLC Control System

A programmable logic controller (PLC) control system is a critical feature in sheet extrusion machines. It allows for precise control over various parameters such as temperature, speed, and thickness, ensuring consistent and repeatable results. The PLC control system also enables easy integration with other production line components, streamlining the overall manufacturing process.

b) Automatic Thickness Control

An efficient sheet extrusion machine should have automatic thickness control capabilities. Advanced sensors and feedback systems continuously monitor and adjust the thickness of the extruded sheet in real-time. This feature eliminates the need for manual adjustments, reducing operator intervention and improving overall productivity.

c) Multi-layer Extrusion

To meet the increasing demand for specialized plastic sheets, many sheet extrusion machines offer multi-layer extrusion capabilities. This feature enables the production of sheets with multiple layers of different materials or colors. Multi-layer extrusion expands the range of products that can be manufactured, adding versatility and market competitiveness.

d) Energy Efficiency

Modern sheet extrusion machines incorporate energy-efficient technologies to reduce power consumption and operating costs. Energy-efficient motors, optimized heating and cooling systems, and intelligent automation contribute to significant energy savings. Manufacturers prioritize sustainability and environmental responsibility by developing machines that minimize their carbon footprint.

e) Quick Changeover and Maintenance

Efficiency can be greatly enhanced by reducing machine downtime during product changeovers or maintenance. Sheet extrusion machines with quick changeover features allow for easy and rapid adjustment of die dimensions, heating settings, and other parameters. Additionally, machines equipped with self-diagnostic capabilities streamline maintenance and troubleshooting processes, minimizing production disruptions.

3. Applications of Plastic Sheets Produced by Sheet Extrusion Machines

Plastic sheets produced by sheet extrusion machines find various applications across multiple industries. Their versatility and customizable properties make them suitable for a wide range of uses.

a) Packaging Industry

Plastic sheets are extensively used in the packaging industry for applications such as food packaging, pharmaceutical packaging, and consumer goods packaging. They offer excellent barrier properties, protection against moisture and contaminants, and superior printability.

b) Construction and Building Materials

Plastic sheets are used in the construction industry for products like roofing sheets, wall claddings, and window profiles. These sheets provide durability, weather resistance, and thermal insulation, while also being lightweight and cost-effective.

c) Automotive Sector

Plastic sheets are utilized in the automotive sector for interior trims, door panels, and exterior parts such as body panels. They offer weight reduction, design flexibility, and improved fuel efficiency.

d) Signage and Display

Plastic sheets are widely employed in the signage and display industry for applications such as advertising displays, lightboxes, and exhibition stands. With excellent transparency, printability, and resistance to outdoor conditions, they provide an ideal material for impactful visual communication.

e) Medical and Healthcare

Plastic sheets find applications in the medical and healthcare sector for products like transparent barriers, sterilized packaging, and disposable medical devices. Their properties, such as chemical resistance, ease of sterilization, and clarity, meet the stringent requirements of the industry.

Conclusion

The sheet extrusion machine is an essential tool for efficient production in the plastic manufacturing industry. Its ability to consistently produce high-quality plastic sheets with various thicknesses and dimensions makes it indispensable in many industrial sectors. By understanding the essential features and functions of a sheet extrusion machine, manufacturers can optimize their production processes, enhance product quality, and expand their market reach.

Using our TENGDA to differentiate our content, services and consumer products, we seek to develop the most creative, innovative and profitable entertainment experiences and related products in the world.

The guiding vision of Nanjing Tengda Machinery Co., Ltd. is 'Bringing the best to everyone we touch'. By 'The best', we mean the best products, the best people and the best ideas.

plastic extruder machine manufacturers problems are nothing new, almost every one of us have to go through them at some point of our lives and some of us never get rid of them. with the development of extruder machine manufacturers technology, now provides a perfect cure for that.