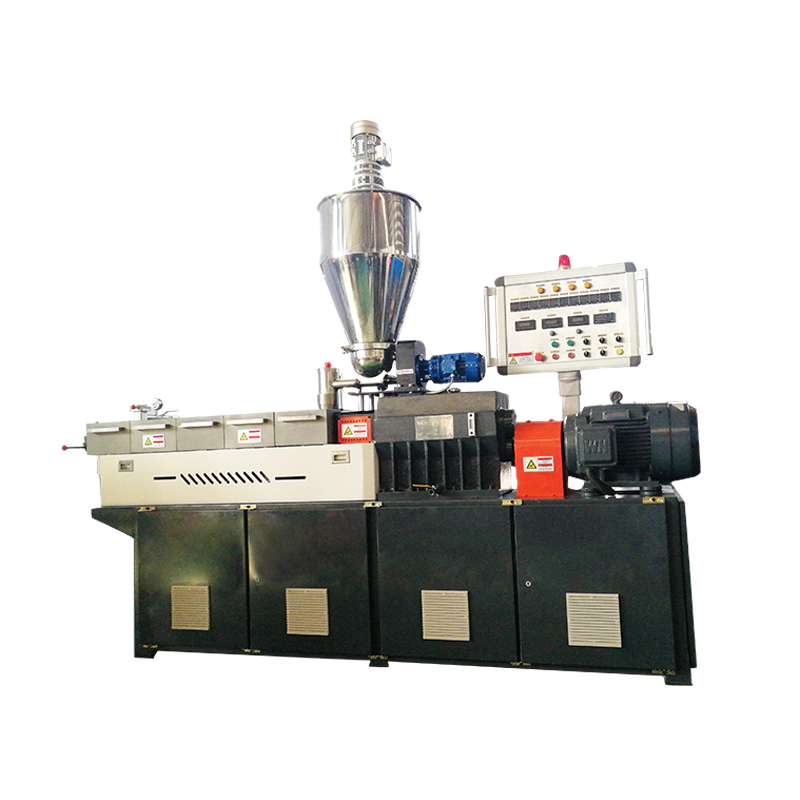

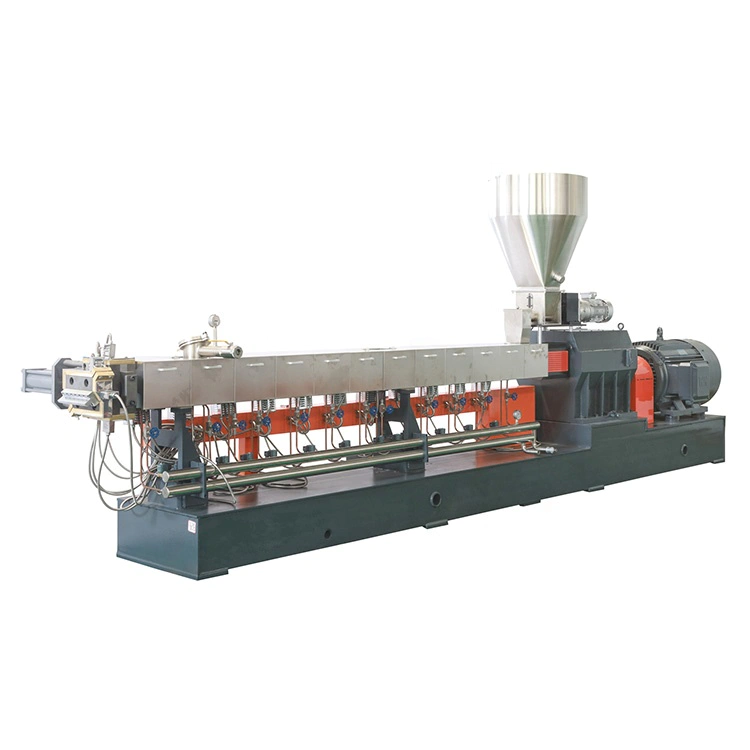

Single Screw Plastic Extruder: Tips for Choosing the Right Size and Capacity

The Importance of Choosing the Right Size and Capacity for a Single Screw Plastic Extruder

Introduction:

When it comes to plastic extrusion, choosing the right size and capacity for a single screw plastic extruder is crucial. The performance and efficiency of the extruder greatly depend on these factors. Whether you are a seasoned professional or a beginner in the plastic extrusion industry, understanding how to choose the appropriate size and capacity is essential. In this article, we will delve into the details of finding the perfect match for your plastic extrusion needs.

Factors to Consider when Choosing a Single Screw Plastic Extruder

Size and capacity determine the output of plastic extrusion processes. Each application requires a specific extruder size and capacity to achieve optimal results. Here are some factors to consider when selecting a single screw plastic extruder:

1. Material Type and Properties

Understanding the material you will be extruding is fundamental. Different materials have distinct properties that affect the extrusion process. Factors such as melt temperature, melt viscosity, and thermal stability influence the choice of extruder size and capacity. Materials with high viscosity or those that require high processing temperatures might need a larger extruder to accommodate the viscosity and heat requirements. On the other hand, materials with low viscosity might perform well with smaller extruders.

2. Output Requirements

Determining the desired output is crucial in selecting the appropriate size and capacity for a single screw plastic extruder. The output is generally measured in pounds per hour (lb/hr) or kilograms per hour (kg/hr). If you have high-volume production requirements, a larger extruder with higher throughput capacity will be necessary. Conversely, for smaller operations, a smaller extruder size with lower throughput capacity may suffice.

3. Extruder Design and Configuration

The design and configuration of the extruder play a significant role in the sizing and capacity selection process. Factors such as the length-to-diameter ratio of the screw, the compression ratio, and the specific screw geometry will influence the extruder's output capabilities. It is crucial to consult with experts or manufacturers to understand the optimal design and configuration for your specific application.

4. Energy Efficiency

In today's environmentally conscious world, energy efficiency is a crucial consideration. While choosing the right size and capacity for a single screw extruder, it is essential to consider the energy consumption of the machine. Larger extruders may require more power to operate, which can lead to increased energy costs. Evaluating the extruder's energy efficiency can help optimize productivity while minimizing environmental impact and operating costs.

5. Future Scalability

Consider your future growth and potential scalability when selecting a single screw plastic extruder. Investing in an extruder with room for expansion can be a strategic move, especially if you anticipate an increase in production demands. Choosing a machine that allows for future upgrades and modifications can save you from the hassle of replacing the entire extrusion system down the line.

In Summary

Choosing the right size and capacity for a single screw plastic extruder is vital to achieve optimal performance and efficiency. Factors like material properties, output requirements, extruder design, energy efficiency, and future scalability should be carefully evaluated. By understanding these considerations, you can make an informed decision and select an extruder that meets your specific plastic extrusion needs.

In conclusion, the comprehensive knowledge of material characteristics and production requirements is crucial in determining the proper size and capacity for a single screw plastic extruder. Carefully considering the factors discussed in this article will empower you to make an informed decision and choose an extruder that will deliver the best results for your plastic extrusion processes. Remember to consult with experts or manufacturers to ensure you make the right choice for your specific application. With the right extruder, you can enhance productivity and efficiency while producing high-quality plastic products.

Nanjing Tengda Machinery Co., Ltd. thinks that that firms can avoid the artificial choice between quantitative and qualitative risk management, allowing both to play important roles in surfacing and assessing risks.

Dedicated to bringing you professional Application solutions and related products – from plastic extruder machine manufacturers to extruder machine manufacturers, Nanjing Tengda Machinery Co., Ltd. is your Application helper. Visit us at TENGDA Extruder Machine Manufacturers.

Armed with professional team and advanced equipment, Nanjing Tengda Machinery Co., Ltd. is specialized in offering high quality in various designs. Visit us at TENGDA Extruder Machine Manufacturers to find your desired .