Single Screw Plastic Extruder: What You Need to Know Before Buying

Introduction

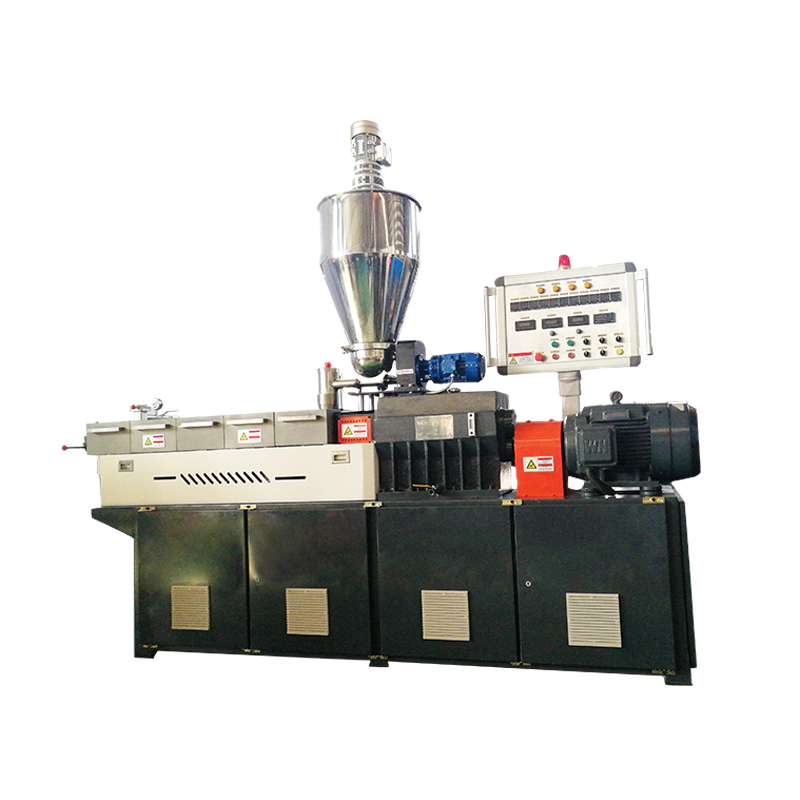

In the field of plastic manufacturing, the single screw plastic extruder plays a pivotal role. It is a highly efficient and versatile machine that is widely used in various industries. Whether you are considering venturing into plastic extrusion or looking to upgrade your existing equipment, it is crucial to have a clear understanding of what a single screw plastic extruder entails before making a purchase. This article will provide you with comprehensive knowledge and insights into the key aspects you should know before buying a single screw plastic extruder.

Advantages of a Single Screw Plastic Extruder

A single screw plastic extruder offers numerous advantages, making it an attractive choice for manufacturers. Firstly, it is a cost-effective option compared to other extrusion methods. The simplicity of its design and fewer components result in lower production costs, making it an ideal choice for small-scale businesses or those with budget constraints.

Secondly, single screw plastic extruders are known for their versatility. They can process a wide range of materials, including various plastics such as polyethylene, polypropylene, PVC, and more. Additionally, they can be adapted to various applications, enabling manufacturers to produce different types of plastic products, including pipes, tubes, profiles, sheets, films, and more. This flexibility allows businesses to diversify their product offerings and cater to different market demands.

Thirdly, single screw plastic extruders are relatively easy to operate and maintain. The single screw design simplifies the extrusion process, making it less complex compared to other extrusion techniques. Moreover, the machine requires minimal maintenance, resulting in higher production efficiency and reduced downtime, thus maximizing profits for the manufacturers.

Moreover, single screw plastic extruders provide excellent control over the extrusion process. They allow precise control of temperature, pressure, and speed, ensuring consistent and high-quality output. This control is essential for meeting specific product requirements and maintaining uniformity in the final products.

Factors to Consider Before Buying a Single Screw Plastic Extruder

While the advantages are clear, there are several crucial factors to consider before investing in a single screw plastic extruder to ensure the machine meets your production needs and business requirements.

1. Application and Material Compatibility

Before purchasing a single screw plastic extruder, it is essential to understand the specific application and materials you will be working with. Different materials require different screw designs, barrel configurations, and processing conditions. For example, if you plan to extrude rigid PVC profiles, you will need a machine with specific screw and barrel materials that can handle the high temperatures required for processing PVC. Therefore, it is crucial to choose a machine that is compatible with your desired materials and application to achieve optimal results.

It is also important to consider whether you will be processing virgin materials or recycled materials. Recycled materials may have different characteristics, such as higher melt temperatures or different flow properties, which will affect the selection of the extruder.

The size and complexity of the products you intend to manufacture should also be taken into account. Larger products may require a machine with a higher extrusion output, while intricate profiles may require a machine with enhanced control over the extrusion process.

2. Output Capacity and Production Efficiency

The desired output capacity and production efficiency are key factors to consider when purchasing a single screw plastic extruder. The output capacity is determined by the screw diameter and the screw's length-to-diameter ratio. A larger screw diameter and a higher length-to-diameter ratio generally result in a higher output capacity. It is crucial to choose a machine that can meet your desired production volumes to avoid bottlenecks in your manufacturing process.

Additionally, consider the overall production efficiency of the machine. Factors such as the extruder's drive system, heating and cooling capabilities, and control systems can significantly impact production efficiency. Look for features that enhance energy efficiency, reduce processing time, and provide consistent output quality.

3. Flexibility and Adaptability

Flexibility and adaptability are vital considerations, especially if you anticipate changes in your production requirements or plan to expand your product range in the future. Look for a single screw plastic extruder that can easily accommodate different materials, processing conditions, and product specifications. This will allow you to adapt to market demands and diversify your product offerings without investing in additional machines or significant modifications.

Some machines offer modular designs that allow for easy screw and barrel changes, enabling manufacturers to switch between different materials efficiently. Additionally, look for extruders that offer adjustable processing variables, such as temperature, screw speed, and torque, to ensure versatility in product manufacturing.

4. Quality and Durability

Investing in a high-quality single screw plastic extruder is essential for long-term productivity and profitability. Look for machines manufactured by reputable companies with a proven track record in the industry. Buy from suppliers who offer reliable after-sales service, warranty, and technical support to ensure smooth operation and minimize downtime.

Consider the build quality of the machine itself. Look for robust construction, durable components, and advanced engineering features that enhance the machine's lifespan and withstand the demanding nature of plastic extrusion processes.

5. Cost and Return on Investment

While cost should not be the sole determining factor, it is essential to consider your budget and evaluate the return on investment (ROI) when purchasing a single screw plastic extruder. Compare the features, specifications, and prices offered by different manufacturers to find the best value for your money without compromising on quality.

Consider the machine's lifespan, maintenance costs, and energy consumption when evaluating the ROI. A machine with lower energy consumption can save on operating costs in the long run, leading to better profitability.

Conclusion

When it comes to purchasing a single screw plastic extruder, thorough research and careful evaluation are crucial. Consider the specific application and materials you will be working with, ensure the machine offers suitable output capacity and production efficiency, prioritize flexibility and adaptability, assess the quality and durability of the machine, and evaluate the cost and ROI. By taking these factors into account, you can make an informed decision and invest in a single screw plastic extruder that will meet your production needs, drive efficiency, and contribute to the success of your plastic manufacturing business.

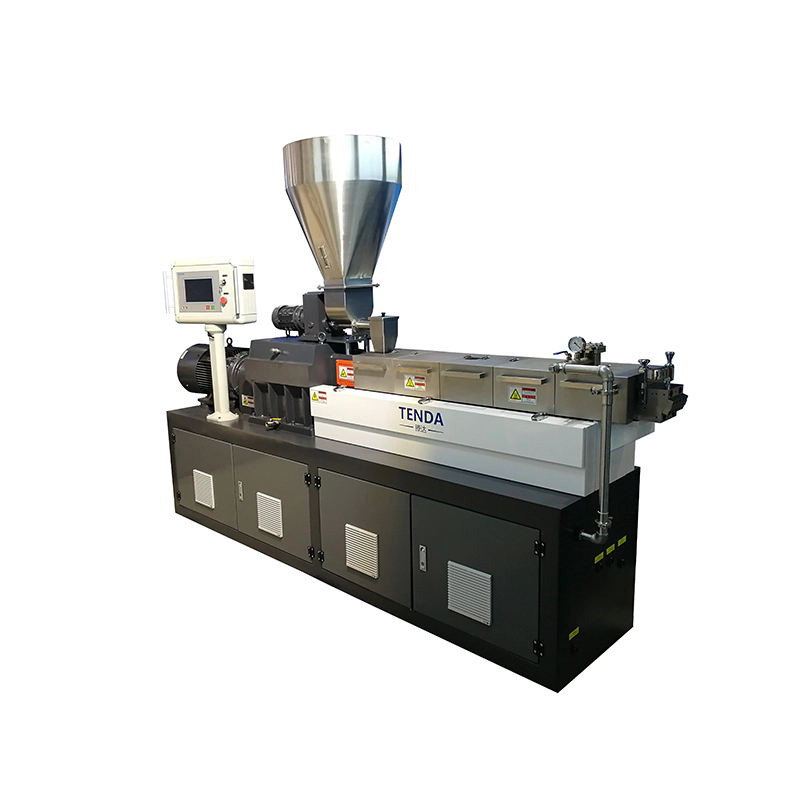

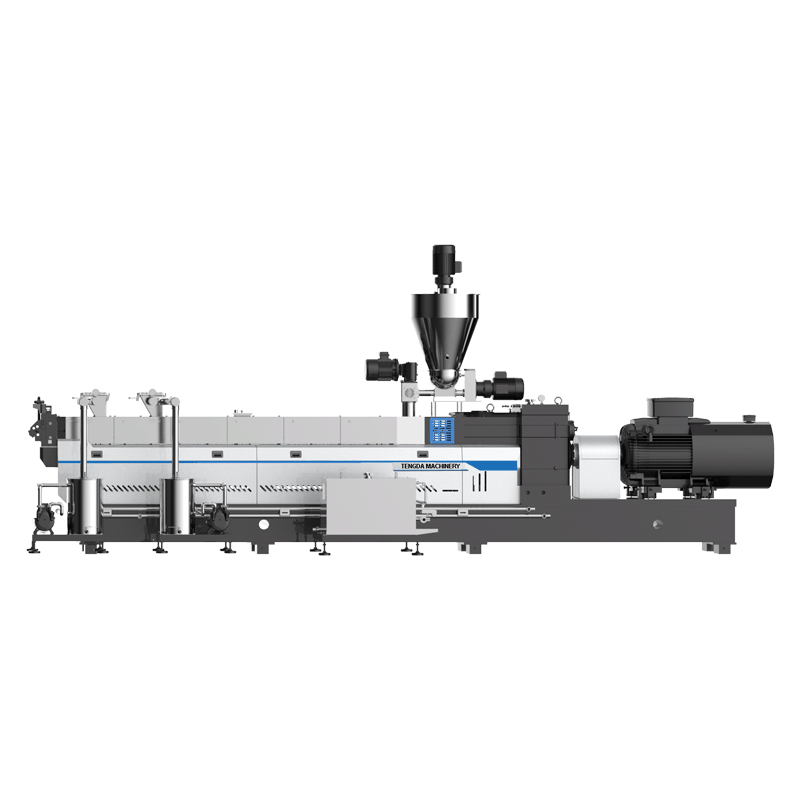

It has become necessary for Nanjing Tengda Machinery Co., Ltd. to continually cultivate, develop and update their skills to work successfully alongside high-tech.

Nanjing Tengda Machinery Co., Ltd. are dedicated to providing excellent underwriting and loss control advice up front, and to ensuring superior customer service through the life of the policy.

To do that, Nanjing Tengda Machinery Co., Ltd. will need to make sure our business is listed accurately on as many directories as possible, including technology and quality.

Looking for Manufacturers in China? Then Nanjing Tengda Machinery Co., Ltd. is the right choice. we are a well known plastic extruder machine manufacturers Application Manufacturers and suppliers from China.

What Nanjing Tengda Machinery Co., Ltd. discovered was that innovation occurs when business models match up with one or more of the Application where technological advances overlap with market needs, thus resulting in growth and transformation.