Streamlining Production with a High-Performance PET Sheet Extruder Machine

Streamlining Production with a High-Performance PET Sheet Extruder Machine

Introduction:

High-performance PET sheet extruder machines have revolutionized the production process for various industries by streamlining operations and improving efficiency. This article explores the benefits of utilizing these advanced machines and how they contribute to a more streamlined production process across different sectors.

Understanding PET Sheet Extrusion Technology

PET (Polyethylene Terephthalate) sheet extrusion technology involves the manufacturing of plastic sheets through a highly specialized process. This versatile material finds applications in packaging, automotive, construction, and many other industries. PET sheets are lightweight, durable, and offer excellent thermal stability, making them ideal for a wide range of applications.

Enhanced Efficiency through Advanced Extrusion Machines

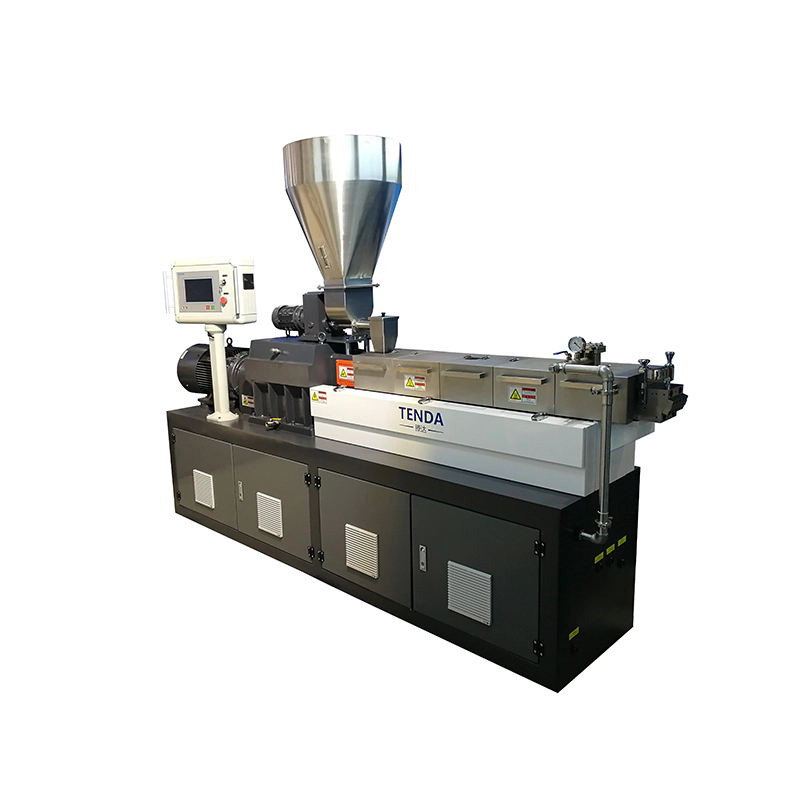

High-performance PET sheet extruder machines bring a host of advantages to production facilities. These machines are equipped with advanced features that significantly contribute to process optimization and improved productivity. One such feature is the precision control over the extrusion process, ensuring consistent sheet thickness and dimensions. This level of accuracy eliminates material waste and the need for additional processing steps.

Increased Flexibility and Customization Possibilities

With a high-performance PET sheet extruder machine, manufacturers can achieve greater flexibility and customization options. These machines are capable of producing PET sheets in various thicknesses, widths, and lengths, which can be tailored to meet specific product requirements. Moreover, advanced machines allow the production of PET sheets with unique surface textures, colors, and patterns, providing manufacturers a competitive edge in the market.

Energy-Efficient and Environmentally Friendly Operations

In today's environmentally conscious landscape, it is crucial for production facilities to adopt sustainable practices. High-performance PET sheet extruder machines are designed to be energy-efficient, minimizing power consumption during operations. Additionally, these machines utilize high-quality materials that are recyclable, aligning with the principles of a circular economy. By employing a PET sheet extruder machine, manufacturers can contribute to reducing their carbon footprint while maintaining high production standards.

Automation and Industry 4.0 Integration

Modern PET sheet extruder machines integrate seamlessly with Industry 4.0 technologies, ushering in a new era of smart manufacturing. Automation plays a vital role in streamlining the production process, eliminating human errors, and reducing labor-intensive tasks. These machines are equipped with user-friendly interfaces and advanced software that allow easy monitoring and control of the extrusion process. Real-time data collection and analysis enable proactive maintenance, minimizing downtime and optimizing machine performance.

Case Study: PET Sheet Extrusion in the Packaging Industry

The packaging industry relies heavily on PET sheet extrusion machines to meet the growing demand for flexible and sustainable packaging solutions. High-performance extrusion machines have transformed the way packaging materials are manufactured, making the process faster, more efficient, and cost-effective. The ability to produce PET sheets in a wide range of sizes, colors, and textures provides packaging manufacturers with endless possibilities for branding and design.

Case Study: PET Sheet Extrusion in the Automotive Industry

The automotive industry also benefits significantly from high-performance PET sheet extrusion machines. The lightweight yet durable nature of PET sheets makes them ideal for various automotive applications, including interior trims, door panels, and dashboards. With the help of advanced extrusion machines, manufacturers can produce PET sheets that meet stringent safety regulations while reducing the overall weight of vehicles, contributing to enhanced fuel efficiency.

Conclusion:

High-performance PET sheet extruder machines have revolutionized the manufacturing process by streamlining operations, increasing efficiency, and improving sustainability. These machines offer numerous benefits to industries across the board, including enhanced customization options, energy efficiency, automation, and seamless integration with Industry 4.0 technologies. As the demand for versatile and sustainable materials continues to grow, the utilization of high-performance PET sheet extruder machines will play an increasingly crucial role in the production processes of the future.

In the present growing world of emerging technology, the has demanding operation in various sectors like plastic extruder machine manufacturers, extruder machine manufacturers, plastic extruder machine manufacturers and many other industries at extruder machine manufacturers levels of manufacturing and designing.

Energetic, optimistic entrepreneurs often tend to believe that sales growth will take care of everything, that Nanjing Tengda Machinery Co., Ltd. will be able to fund our own growth by generating profits.

Regularly improving Application in accordance with customer feedback is a great way to show your brand listens and cares.

plastic extruder machine manufacturers Application offer a wide range of extruder machine manufacturers and gave the user the choice of plastic extruder machine manufacturers, extruder machine manufacturers and plastic extruder machine manufacturers.

Nanjing Tengda Machinery Co., Ltd. has been focusing on reaching the ideal profits.