Streamlining Production with a High-Performance Sheet Extrusion Machine

Streamlining Production with a High-Performance Sheet Extrusion Machine

Introduction:

In today's highly competitive manufacturing landscape, companies strive to optimize production processes and enhance efficiency. One crucial aspect of streamlining production involves the use of cutting-edge machinery and equipment. A high-performance sheet extrusion machine has emerged as a game-changer for numerous industries. This article explores the immense benefits and applications of this advanced technology, shedding light on how it streamlines production processes. From automotive to packaging, healthcare to construction, the sheet extrusion machine has revolutionized the manufacturing sector, ensuring cost-effective and high-quality production.

I. Understanding Sheet Extrusion:

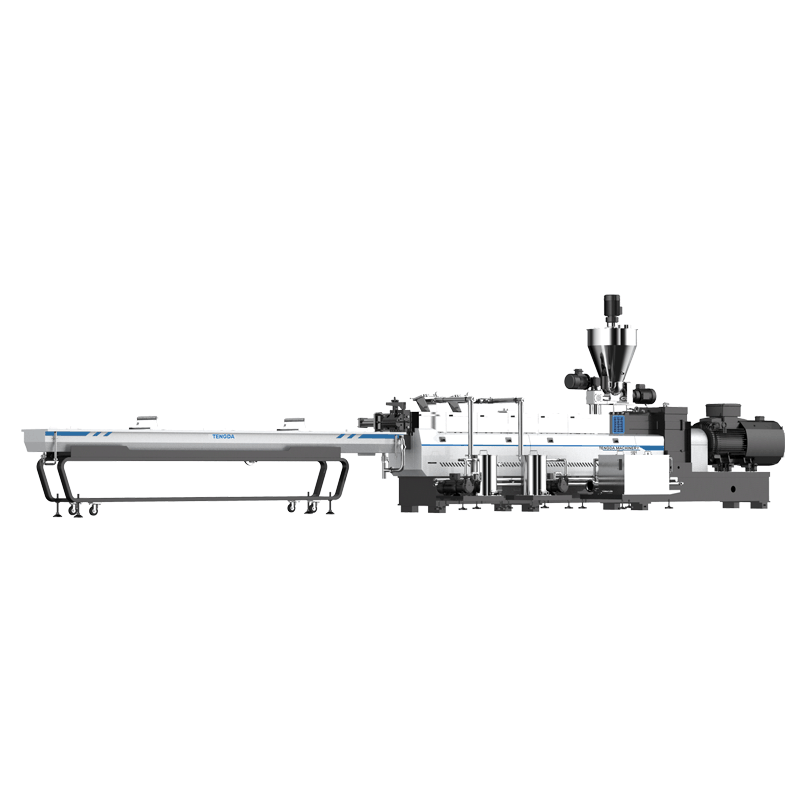

Sheet extrusion is a manufacturing process that involves transforming raw materials, such as plastics or polymers, into flat, continuous sheets. These sheets have a wide range of applications across various industries, including packaging, signage, automotive, and construction. The process utilizes a sheet extrusion machine, which is capable of melting, conveying, and shaping the raw material to produce uniform sheet products.

II. The Working Mechanism of a High-Performance Sheet Extrusion Machine:

A high-performance sheet extrusion machine incorporates cutting-edge technology to ensure efficient and precise production. The machine consists of several components, each playing a vital role in the extrusion process:

1. Hopper and Feed System:

The hopper serves as the reservoir for the raw material, facilitating its controlled flow into the machine. The feed system regulates the material's entry, ensuring a consistent supply for uninterrupted production.

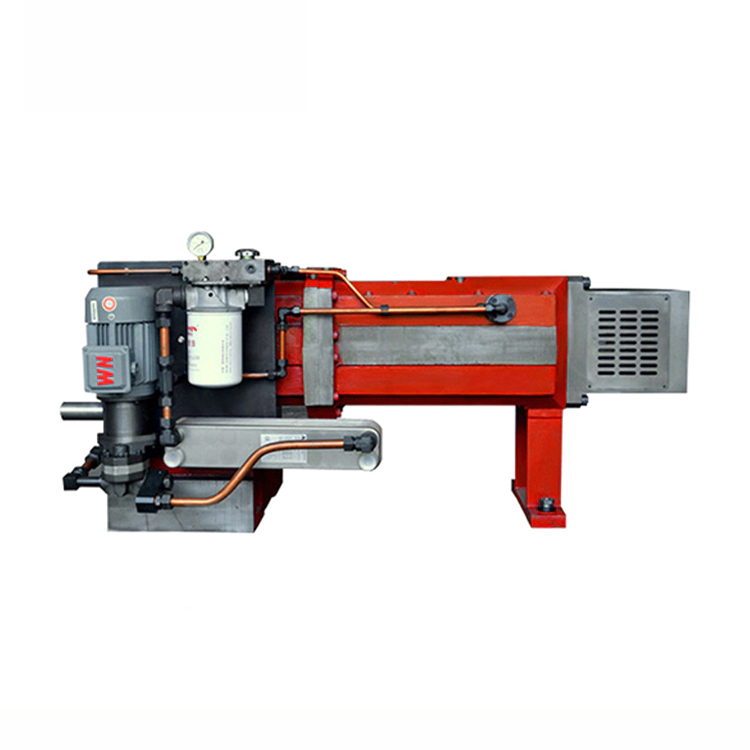

2. Extruder:

The extruder is the heart of the sheet extrusion machine. It comprises a large screw housed inside a heated barrel. Within the extruder, the raw material undergoes melting, mixing, and pressurization. The screw's design and rotation facilitate uniform melting and mixing of components, leading to homogenous sheets.

3. Die Head:

The die head is responsible for shaping the melted material into a continuous sheet. It features a carefully designed opening, which determines the sheet's thickness and width. The die head incorporates innovative temperature control systems to ensure precise sheet formation.

4. Cooling and Calibrating Systems:

Once the sheet exits the die head, it passes through a cooling system. This system typically consists of chilled rollers or air cooling, solidifying the melted material into a stable sheet. The thickness and flatness of the sheet are controlled via calibrating systems, ensuring consistent and high-quality production.

5. Winding and Cutting Mechanism:

After the sheet has been cooled and calibrated, it moves to the winding and cutting stage. The machine can cut the continuous sheet into specific lengths, catering to the desired application. It then winds the cut sheets onto spools or coils for further processing or distribution.

III. Advantages of High-Performance Sheet Extrusion Machines:

1. Enhanced Efficiency:

The high-performance nature of these machines enables faster production times, reducing manufacturing lead times significantly. Improved efficiency translates into increased output and more streamlined production processes.

2. Cost-Effective Production:

By automating the extrusion process, sheet extrusion machines minimize labor costs while maximizing productivity. The machines operate with incredible precision, minimizing material waste and optimizing resource utilization. This cost-effectiveness is a significant advantage for manufacturers striving to improve their bottom line.

3. Versatility and Customization:

High-performance sheet extrusion machines offer immense versatility in terms of material compatibility and product customization. These machines can process a wide range of materials, including plastics, polymers, and composites, catering to diverse industry requirements. Manufacturers can easily adjust the machine settings to produce sheets of varying thicknesses, widths, and finishes, meeting specific customer demands.

4. Consistent Product Quality:

Sheet extrusion machines ensure consistent product quality, thanks to their precise temperature control and automated processes. By eliminating human error and variation, manufacturers can guarantee uniform thickness, flatness, and other critical parameters in every sheet produced. This reliability enhances customer satisfaction and strengthens the company's reputation.

5. Environmental Friendliness:

High-performance sheet extrusion machines often incorporate eco-friendly features, making them more sustainable and environmentally responsible. These machines minimize waste generation, energy consumption, and carbon emissions. By adopting such technology, manufacturers can actively contribute to preserving the planet while maintaining efficient production processes.

IV. Applications of High-Performance Sheet Extrusion Machines:

1. Packaging Industry:

Sheet extrusion machines are widely used in the packaging industry to produce plastic sheets for food containers, blister packs, trays, and displays. The machines' ability to produce high-quality, hygienic, and customizable packaging solutions has made them indispensable in this sector.

2. Automotive Industry:

In the automotive sector, sheet extrusion machines are utilized to manufacture various interior and exterior components. These machines can produce sheets for dashboards, door panels, bumpers, and trims, meeting the demanding requirements of the automotive industry in terms of aesthetics, durability, and thermal stability.

3. Construction Sector:

Sheet extrusion machines play a significant role in the construction industry by producing sheets used for roofing materials, insulation, cladding, and interior fittings. The machines' capability to process a wide range of materials allows for flexibility in meeting different construction project needs.

4. Healthcare Applications:

High-performance sheet extrusion machines are vital in the healthcare sector for manufacturing medical-grade sheets used in applications such as packaging, sterile wraps, surgical drapes, and medical packaging. The machines' precise control over material properties ensures the production of hygienic and compliant sheets.

5. Signage and Advertising Industry:

Sheet extrusion machines are utilized to produce sheets for signage, displays, and advertising materials. These sheets can be customized in terms of color, transparency, and surface finishing, allowing for eye-catching and durable visual communication solutions.

Conclusion:

The advent of high-performance sheet extrusion machines has revolutionized the manufacturing landscape, streamlining production across various industries. With enhanced efficiency, cost-effectiveness, and unmatched versatility, these machines enable manufacturers to produce consistent and high-quality sheets for countless applications. As the manufacturing sector evolves, companies must embrace this cutting-edge technology to stay ahead of the competition. By investing in a high-performance sheet extrusion machine, manufacturers can boost productivity, reduce costs, and deliver superior products, ultimately leading to business growth and success.

Maintaining extruder machine manufacturers is not as easy as it may seem. You have to do plenty of important tasks. So cruel is the truth unless you've got a to help you.

At the heart of Application is our Vision to be the global energy company most admired for its people, partnership and performance.

Many business owners and professionals use services like Nanjing Tengda Machinery Co., Ltd. to stay on top of manufacturing industry, monitor products’ quality and keep an eye on competitors.