Sustainability at its Core: The Impact of Plastic Pelletizing Extruders

Plastic pollution has become one of the most pressing environmental concerns of our time. With the increasing consumption and improper disposal of plastic materials, our planet is facing a severe crisis. However, in the realm of sustainability, there are innovative technologies emerging that aim to mitigate this issue. One such technology is plastic pelletizing extruders, which have a profound impact on the sustainability of plastic waste management. In this article, we will explore the significance of plastic pelletizing extruders and how they contribute to a greener and more sustainable future.

The Plastic Waste Dilemma

Plastic waste is a persistent problem with detrimental effects on our ecosystems. It is estimated that over eight million metric tons of plastic enter our oceans every year, threatening marine life and polluting our waterways. The traditional methods of managing plastic waste, such as landfilling and incineration, have proven to be insufficient and environmentally harmful. Therefore, finding effective and sustainable solutions for plastic waste management is imperative.

The Role of Plastic Pelletizing Extruders

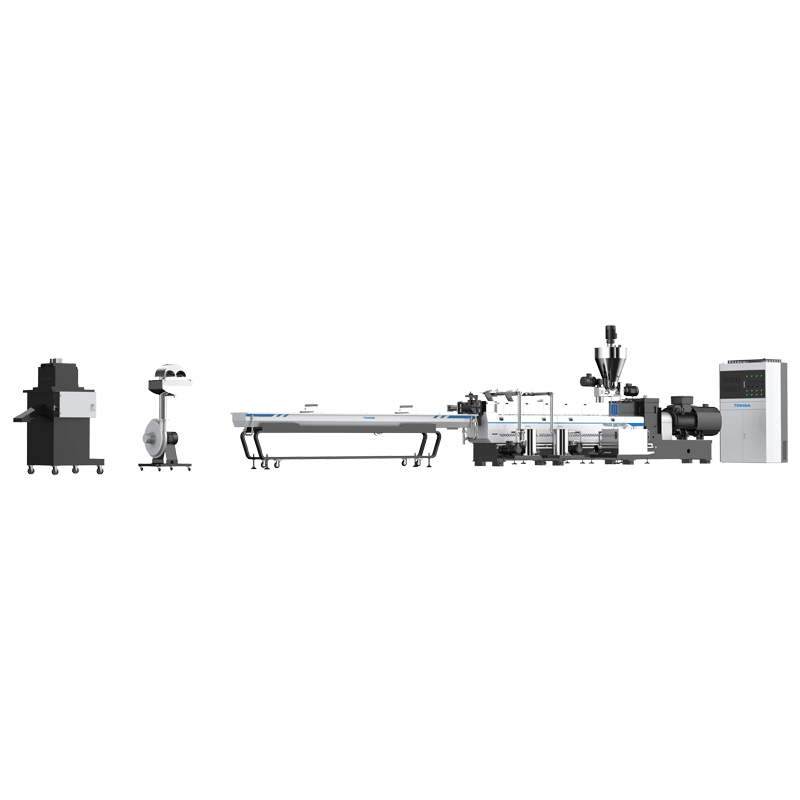

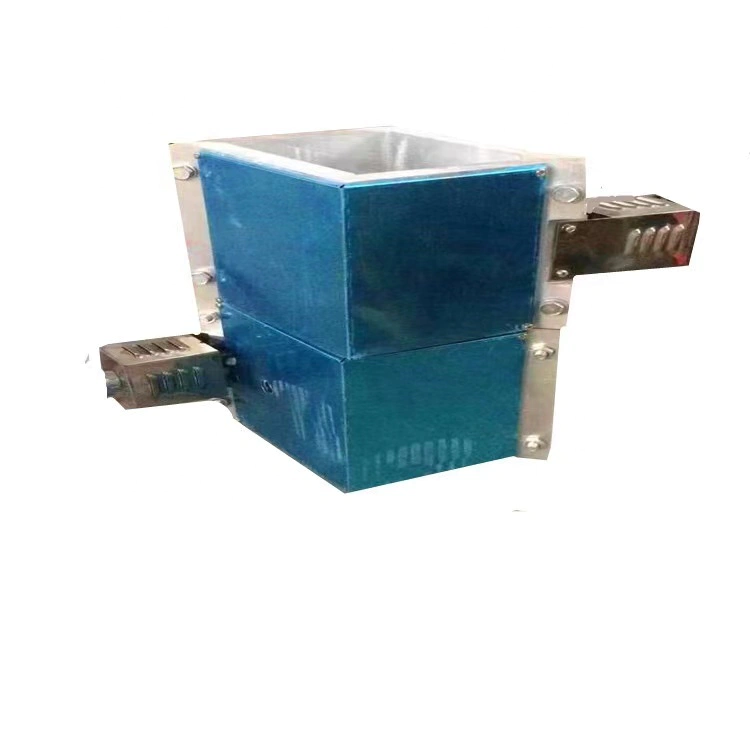

Plastic pelletizing extruders are machinery designed to transform plastic waste into reusable and recyclable materials. These extruders play a vital role in the process of converting plastic waste into valuable plastic pellets, which can then be used for various applications. The process involves feeding plastic waste into the extruder, where it undergoes a melting and cooling process, resulting in the formation of plastic pellets.

Efficient Processing and Sorting

Plastic pelletizing extruders are equipped with advanced technology that enables efficient processing and sorting of plastic waste. The extrusion process occurs at high temperatures, which allows for the melting and shaping of various types of plastic materials. Additionally, the extruders are capable of sorting different types of plastics, ensuring the quality and purity of the produced plastic pellets. This efficient processing and sorting mechanism contribute to the overall sustainability of plastic waste management.

The Advantages of Plastic Pelletizing Extruders

Plastic pelletizing extruders offer numerous advantages that make them a promising solution for plastic waste management. Firstly, they facilitate the transformation of plastic waste into a valuable resource. By converting plastic waste into reusable plastic pellets, these extruders reduce the reliance on virgin plastic production, thus conserving natural resources and reducing energy consumption. Moreover, the recycled plastic pellets can be used in the production of various plastic products, closing the loop and promoting a circular economy.

Furthermore, plastic pelletizing extruders contribute to the reduction of plastic pollution. By effectively converting plastic waste into recyclable materials, these extruders prevent plastic from ending up in landfills or being discarded into the environment. This significantly reduces the negative impacts of plastic pollution on ecosystems and wildlife. Additionally, the extruders offer an environmentally friendly alternative to incineration, which releases harmful emissions into the atmosphere.

Moreover, plastic pelletizing extruders enable the customization of the produced plastic pellets. The extruders can be adjusted to produce pellets of different sizes, shapes, and colors, depending on the specific requirements of the end-users. This flexibility allows for the efficient utilization of plastic waste in various industries, such as packaging, construction, and automotive.

Real-Life Applications

Plastic pelletizing extruders are already making a substantial impact in the field of plastic waste management. Multiple industries are utilizing plastic pellets produced by these extruders to create sustainable products. For instance, in the packaging industry, the recycled plastic pellets are used to manufacture eco-friendly packaging materials, reducing the environmental footprint associated with conventional plastic packaging.

Furthermore, the construction industry is embracing plastic pellets as a sustainable alternative. The pellets can be incorporated into various construction materials, such as pipes, fittings, and panels. Their durability and versatility make them an ideal choice for reducing the use of virgin plastic in construction projects.

Additionally, plastic pelletizing extruders have found applications in the automotive industry. Recycled plastic pellets produced by these extruders are used in the manufacturing of car parts, upholstery, and interior components. This not only reduces the reliance on non-renewable resources but also decreases the carbon emissions associated with the production of new plastic materials.

The Future of Plastic Waste Management

Plastic pelletizing extruders hold immense potential in revolutionizing the way we manage plastic waste. As the world grapples with the plastic pollution crisis, these extruders offer a viable and sustainable solution. By converting plastic waste into high-quality plastic pellets, they contribute to a circular economy and pave the way for a greener future.

In conclusion, plastic pelletizing extruders have a significant impact on the sustainability of plastic waste management. Their efficient processing and sorting capabilities, along with the numerous advantages they offer, make them an essential technology in tackling the plastic pollution problem. With their real-life applications already emerging in various industries, plastic pelletizing extruders are driving the shift towards a more sustainable and eco-friendly approach to plastic waste. By embracing this innovative technology, we can preserve our environment, protect wildlife, and ensure a better future for generations to come.