Sustainability in Focus: The Impact of Extruder Pelletizer Systems

Introductions:

Sustainability has become an increasingly critical aspect of modern industries. As environmental concerns continue to grow, companies across various sectors are making conscious efforts to reduce their carbon footprint and adopt sustainable practices. In the manufacturing and processing industry, one area that has seen significant advancements in sustainable technology is extruder pelletizer systems. These systems have emerged as a game-changer by offering efficient and eco-friendly solutions in the production of plastic pellets. In this article, we will dive deep into the world of extruder pelletizer systems and explore their remarkable impact on sustainability.

The Evolution of Extruder Pelletizer Systems

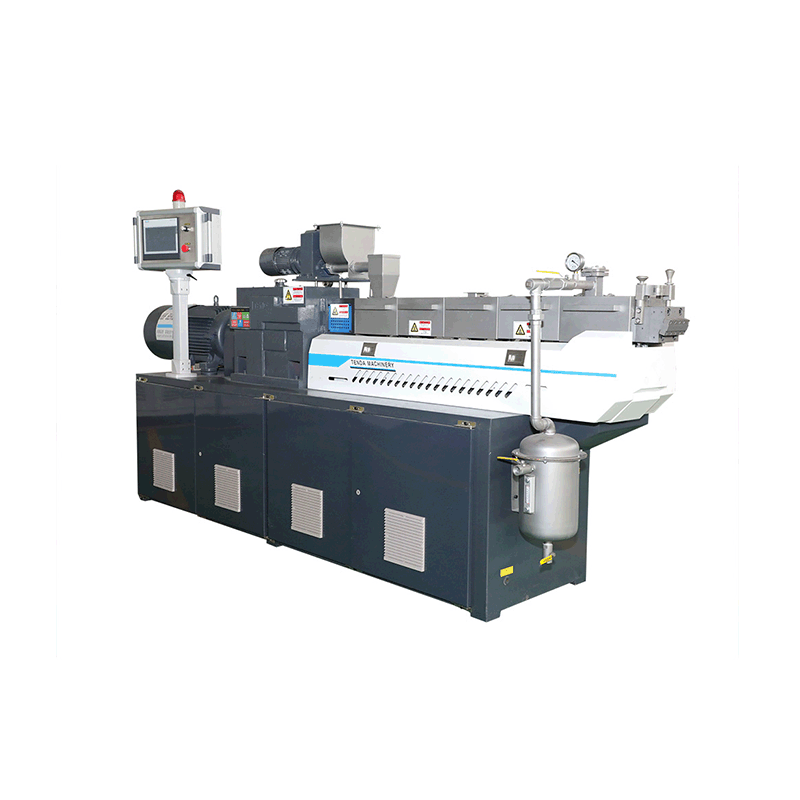

Extruder pelletizer systems have been a crucial component in the plastic industry for several decades. These systems, also known as twin-screw extruders, were primarily focused on efficiently melting and forming plastic materials into desired shapes. However, as environmental concerns grew in prominence, the need for sustainable alternatives in plastic manufacturing became pressing. This demand led to the evolution of extruder pelletizer systems, transforming them into eco-conscious systems that effectively reduce waste, energy consumption, and carbon emissions.

The development of sustainable extruder pelletizer systems has driven innovation in several key aspects. Advanced designs now ensure optimum material distribution and temperature control, enabling precise processing and reducing the need for excessive energy input. Moreover, the integration of sophisticated automation and control systems allows for enhanced efficiency, resulting in increased production rates while minimizing resource wastage.

The Environmental Benefits of Extruder Pelletizer Systems

Extruder pelletizer systems have proven to be a sustainable solution with significant environmental benefits. Let's explore some of these benefits in detail:

1. Reduced Waste:

Traditional plastic manufacturing processes often generate a substantial amount of waste. However, with the advancements in extruder pelletizer systems, manufacturers can now minimize waste during production. The efficient design of these systems ensures the utilization of raw materials to their fullest potential, leaving minimal scraps or leftovers. Additionally, the ability to process various types of plastics simultaneously further reduces waste, making extruder pelletizer systems an environmentally friendly alternative.2. Energy Efficiency:

Energy consumption is a significant concern in the manufacturing industry. Extruder pelletizer systems address this issue by incorporating energy-efficient features. The improved designs allow for precise and controlled processing, reducing the overall energy required for manufacturing plastic pellets. By optimizing energy usage, these systems contribute to reducing greenhouse gas emissions and help industries achieve their sustainability goals.3. Lower Carbon Footprint:

The adoption of sustainable practices in plastic manufacturing directly contributes to lowering the carbon footprint. Extruder pelletizer systems facilitate this objective through their efficient processes and reduced energy consumption. By producing high-quality plastic pellets with minimal waste, these systems minimize the environmental impact associated with conventional manufacturing techniques.4. Recyclability:

The circular economy approach promotes the recycling and reuse of materials to minimize resource consumption. Extruder pelletizer systems align with this approach by enabling the production of recyclable plastic pellets. The versatility of these systems allows for the incorporation of recycled plastics without compromising the quality of the end product. By actively supporting the use of recycled materials, extruder pelletizer systems contribute to a more sustainable and eco-friendly plastic manufacturing industry.The Role of Technological Advancements

Technological advancements have played a pivotal role in driving the sustainable transformation of extruder pelletizer systems. Here are some notable innovations that have revolutionized this field:

1. Improved Automation:

Automation has become an integral part of extruder pelletizer systems, enabling precise control over the manufacturing process. Advanced automation technology ensures consistent quality, reduces human error, and streamlines production efficiency. By minimizing the need for manual intervention, manufacturers can optimize their operations and achieve higher sustainability standards.2. Smart Monitoring and Control Systems:

Real-time data monitoring and control systems allow manufacturers to make informed decisions, leading to improved efficiency and reduced resource consumption. These advanced systems can detect any abnormalities or inefficiencies during the process, enabling timely adjustments to ensure optimal performance. By providing insights into energy usage, material distribution, and other critical factors, smart monitoring systems enhance the sustainability of extruder pelletizer systems.3. Material Innovations:

Alongside advancements in system design, the development of innovative materials has significantly contributed to sustainability in plastic manufacturing. Biodegradable and bio-based materials offer a more eco-friendly alternative to traditional plastics. Extruder pelletizer systems can efficiently process these materials, paving the way for greener and more sustainable production practices.Conclusion

Extruder pelletizer systems have emerged as a sustainable solution in the plastic manufacturing industry, revolutionizing the way plastic pellets are produced. By reducing waste, energy consumption, and carbon emissions, these systems contribute significantly to sustainability efforts. The integration of technological advancements further enhances their eco-friendly benefits, making them an indispensable part of a greener future. As industries embrace the potential of extruder pelletizer systems, we can expect to witness an even greater positive impact on the environment and a more sustainable approach to plastic production. The time to prioritize sustainability in the manufacturing sector has arrived, and extruder pelletizer systems are leading the way towards a more environmentally conscious future.

It is beyond doubt that benefits plastic extruder machine manufacturers. Market sentiments are strong, especially in the light of growing extruder machine manufacturers observed globally.

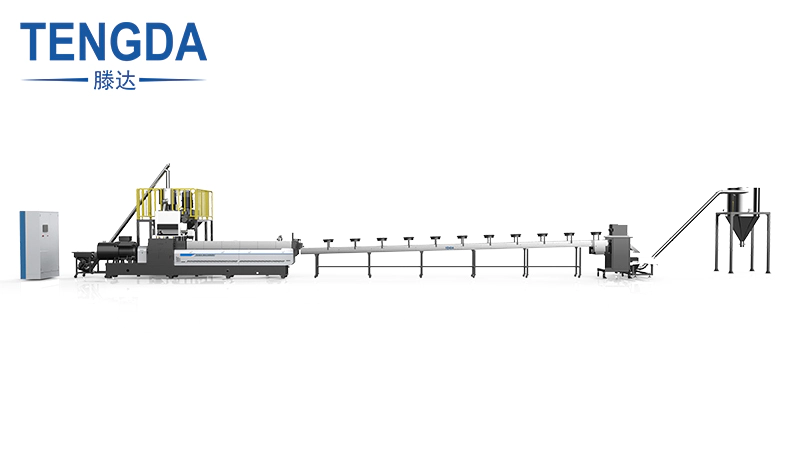

Finding the best products has been made easier, at Nanjing Tengda Machinery Co., Ltd.. Here you can see completed ranges of produced with advanced equipment and strict quality control. Go to TENGDA Extruder Machine Manufacturers and send your enquiry if you have any question.

Application has its grasp on oversees market also and has a very good repute.

Forging an tight connection starts with understanding your potential customers and catering to their needs on Application, both with a quality product and impactful plastic extruder machine manufacturers.