Sustainable Solutions: The Role of Extruder Pelletizer Systems

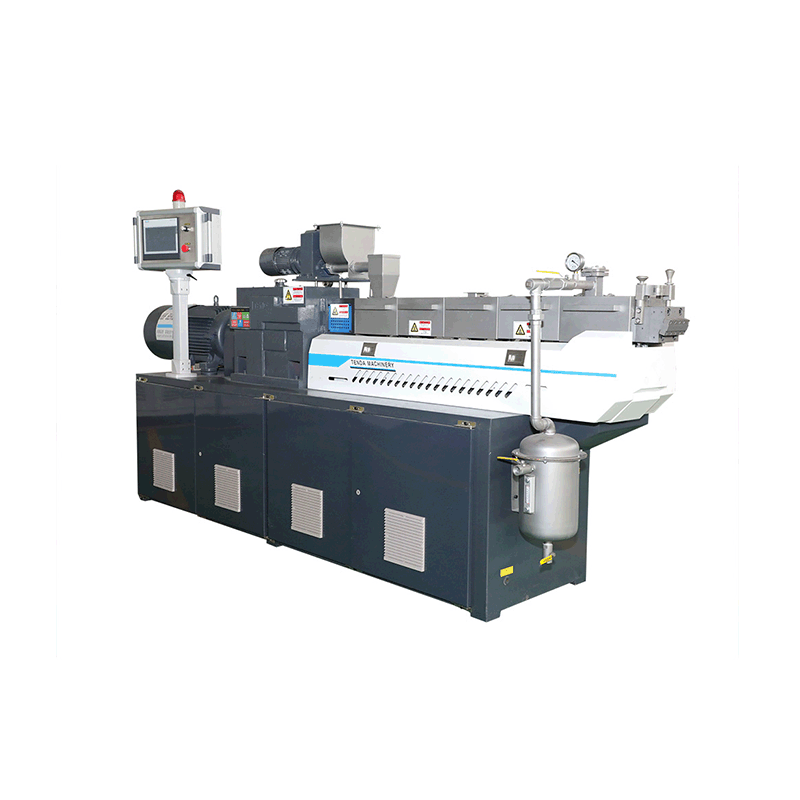

The ever-increasing demand for sustainable solutions has become a pressing issue in the world today. As industries strive to minimize their environmental footprint, the need for innovative technologies has become paramount. In this context, extruder pelletizer systems have emerged as a key player in achieving sustainable production processes. These systems are designed to transform various materials into uniform pellets, offering numerous advantages in terms of resource efficiency, waste reduction, and energy savings. This article explores the role of extruder pelletizer systems in sustainable solutions and highlights their potential in revolutionizing industries across the globe.

Enhancing Resource Efficiency through Extruder Pelletizer Systems

Extruder pelletizer systems play a crucial role in enhancing resource efficiency in industrial processes. By converting raw materials into compact pellets, these systems enable companies to maximize the utility of their resources. Whether it is plastic, food, or pharmaceuticals, extruder pelletizers can process a wide range of materials, making them versatile tools for different industries.

One of the primary benefits of extruder pelletizer systems is their ability to minimize material waste. Traditional production methods often result in significant material loss due to irregular shapes or inconsistent sizes of the end products. However, extruder pelletizers ensure uniformity in size and shape, thus reducing waste to a minimum. Additionally, these systems allow for the use of recycled materials, further optimizing the utilization of resources and contributing to a circular economy.

Moreover, extruder pelletizer systems are highly efficient in terms of material handling. The continuous processing capabilities of these systems enable a seamless workflow, eliminating the need for manual intervention and minimizing downtime. This not only enhances productivity but also reduces the labor and energy required to operate the systems. By streamlining the production process, extruder pelletizers effectively contribute to sustainable industrial practices.

Reducing Environmental Footprint with Extruder Pelletizer Systems

Extruder pelletizer systems play a pivotal role in reducing the environmental footprint of industries. As sustainability becomes a global imperative, minimizing energy consumption and carbon emissions is of utmost importance. Extruder pelletizers are designed to optimize energy efficiency, making them an eco-friendly choice for various applications.

One of the key features of extruder pelletizers is their ability to operate at high speeds while maintaining low energy consumption. This is achieved through the integration of advanced technologies and innovative design elements. The efficient transfer of heat and pressure within the system ensures minimal energy loss during processing. Additionally, the use of electric motors with high power-to-weight ratios further enhances energy efficiency.

In conjunction with energy savings, extruder pelletizer systems also contribute to a reduction in carbon emissions. By enabling the use of recycled materials and reducing material waste, these systems help mitigate the environmental impact associated with resource extraction and production. Moreover, the streamlined workflow and continuous processing capabilities of extruder pelletizers result in a shorter production cycle, further reducing the carbon footprint of industries.

Revolutionizing Industries through Extruder Pelletizer Systems

Extruder pelletizer systems have the potential to revolutionize industries across the globe by providing sustainable solutions to intricate manufacturing processes. From the plastics industry to the food and pharmaceutical sectors, these systems offer a multitude of benefits that can transform the way products are manufactured.

In the plastics industry, extruder pelletizer systems enable the production of high-quality pellets with consistent properties. This not only enhances the performance of plastic products but also facilitates recycling and reusing of materials, thus ensuring a closed-loop system. Additionally, the versatility of extruder pelletizers allows for the incorporation of additives and fillers, further enhancing the functionality of the end products.

In the food industry, extruder pelletizer systems are widely used to produce cereals, snacks, and pet foods. The ability to precisely control the size, shape, and density of the pellets enables manufacturers to create products with desired textures and flavors. Furthermore, the continuous processing capabilities of these systems ensure uniform cooking and sterilization, ultimately resulting in safe and high-quality food products.

Similarly, in the pharmaceutical industry, extruder pelletizer systems are instrumental in the production of controlled-release and taste-masked formulations. The precise control over the composition and characteristics of the pellets allows for the development of innovative drug delivery systems. With extruder pelletizers, pharmaceutical companies can enhance the bioavailability of drugs and improve patient compliance.

Summary

Extruder pelletizer systems have emerged as sustainable solutions that offer resource efficiency, minimize waste, and reduce energy consumption. With their ability to transform various materials into uniform pellets, these systems are revolutionizing industries across the globe. By enhancing resource efficiency, reducing the environmental footprint, and providing innovative manufacturing capabilities, extruder pelletizer systems have become indispensable tools in the pursuit of sustainable production processes. As industries continue to prioritize sustainability, the role of extruder pelletizer systems is set to expand, bringing about a positive impact on both economic growth and environmental conservation.