Twin Screw Extruder Machines: Powering the Plastic Industry Forward

Plastic has become an essential part of our lives, with its presence in almost every industry imaginable. From packaging materials to automotive components, the demand for high-quality plastic products continues to grow. One of the key factors behind the success of the plastic industry is the use of twin screw extruder machines. These machines play a crucial role in shaping and transforming raw plastic materials into finished goods. By employing advanced technology and innovative design, twin screw extruder machines have revolutionized plastic manufacturing processes and propelled the industry forward.

The Evolution of Twin Screw Extruder Machines

In order to understand the significance of twin screw extruder machines, it is important to delve into their evolution. The concept of extrusion dates back to the late 18th century, but it was not until the mid-20th century that twin screw extrusion technology was introduced. Initially, single screw extruders were the industry standard, but they had limitations in terms of processing a wide range of materials and achieving optimum product quality.

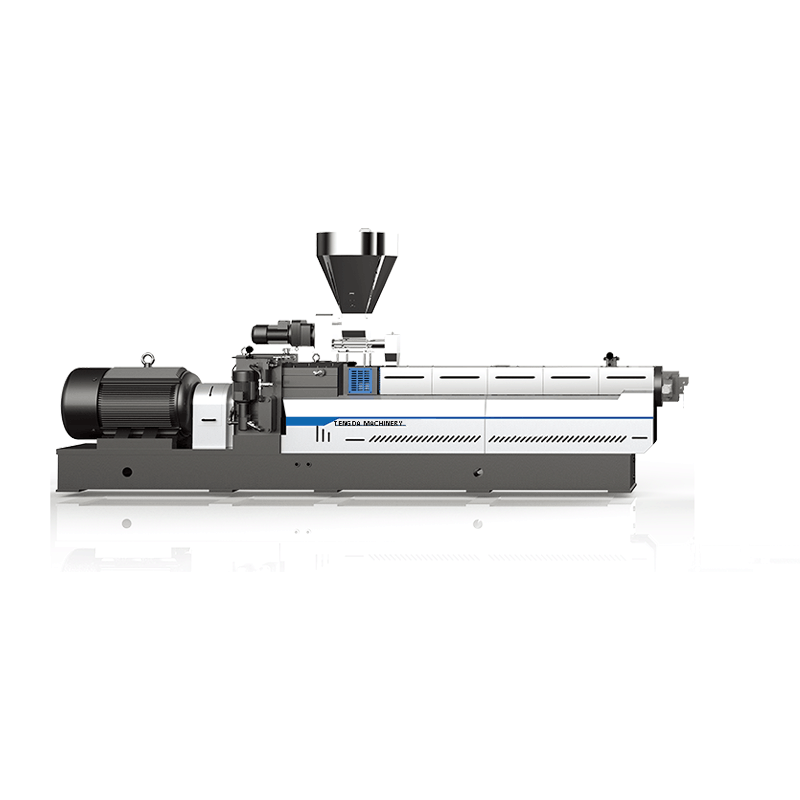

Twin screw extrusion machines were developed to overcome these limitations by offering enhanced mixing capabilities and improved processing efficiency. The twin screw design consists of two intermeshing screws operating inside a barrel, which enables better control over material flow, temperature, and melt homogeneity. This innovative design paved the way for greater versatility in plastic processing, allowing manufacturers to create a diverse range of plastic products with superior quality.

The Advantages of Twin Screw Extruder Machines

The superiority of twin screw extruder machines lies in their ability to provide exceptional mixing and compounding functions. The co-rotating screws within the machine work together to generate intense shear forces and distribute additives evenly throughout the melt. This results in a uniformly blended mixture, ensuring consistent product quality and performance. Moreover, twin screw extruders are highly efficient in melting and conveying plastic materials, enabling faster production cycles and reducing energy consumption.

One of the key advantages offered by twin screw extrusion technology is its flexibility in processing various types of polymers. Whether it is thermoplastics, thermosets, elastomers, or biopolymers, twin screw extruder machines can effectively handle a wide range of materials. This versatility is particularly valuable in industries where multiple materials need to be processed, such as the automotive or medical sectors. Furthermore, the modular design of twin screw extruders allows for easy customization and scalability, making them suitable for both small-scale and large-scale production.

Applications of Twin Screw Extruder Machines

The applications of twin screw extruder machines are vast and span across numerous industries. Let's explore some of the key sectors that benefit from the utilization of these machines:

1. Packaging Industry: Twin screw extruders play a crucial role in the packaging industry by manufacturing plastic films, sheets, and laminates. These machines enable precise control over the thickness, durability, and barrier properties of packaging materials, ensuring product protection and extended shelf life. Additionally, twin screw extrusion technology allows for the incorporation of additives such as colorants, antistatic agents, or UV stabilizers, enhancing the visual appeal and functionality of packaging products.

2. Construction Sector: The construction industry heavily relies on twin screw extruders for the production of various plastic materials used in building and infrastructure projects. These machines are used to manufacture PVC pipes, profiles, panels, and other components required for plumbing, electrical wiring, flooring, and insulation purposes. With the ability to process different types of polymers and achieve precise dimensional control, twin screw extruders contribute to the development of durable and sustainable construction solutions.

3. Automotive Manufacturing: Twin screw extrusion technology has revolutionized the automotive industry by enabling the production of lightweight and high-performance plastic components. From interior trim parts to exterior body panels, these machines can process engineering polymers that exhibit excellent mechanical properties, heat resistance, and chemical resistance. By replacing traditional metal parts with plastic counterparts, vehicle manufacturers can achieve weight reduction, fuel efficiency improvement, and enhanced design possibilities.

4. Medical and Pharmaceutical Fields: Twin screw extruders have found extensive use in the medical and pharmaceutical industries for the production of precision medical devices, drug delivery systems, and biocompatible materials. The ability to mix and extrude different polymers while maintaining stringent quality standards ensures the fabrication of safe and reliable medical products. Furthermore, twin screw extrusion technology facilitates the incorporation of active pharmaceutical ingredients (APIs) into polymer matrices, enabling controlled release and targeted drug delivery.

5. Food Processing and Packaging: The food industry benefits from twin screw extruder machines in various ways, including the production of extruded snacks, cereal products, textured vegetable proteins, and functional ingredients. These machines allow for precise control over the extrusion process, ensuring consistency in product size, shape, and texture. Moreover, twin screw extruders enable the incorporation of vitamins, minerals, and additives into food products, enhancing nutritional value and sensory attributes.

Conclusion

Twin screw extruder machines have undoubtedly become the driving force behind the plastic industry's growth and innovation. Their advanced technology, unmatched mixing capabilities, and versatility in processing various materials have opened up new possibilities in numerous sectors. From packaging materials to automotive components, the applications of twin screw extrusion technology are vast and continue to expand. As technology progresses and manufacturers seek more sustainable and efficient plastic production methods, twin screw extruder machines will undoubtedly remain at the forefront of the plastic industry, powering it forward into a greener and more advanced future.

Nanjing Tengda Machinery Co., Ltd. specializes in undertaking corporate offers to cater the needs of different companies.

We are an experienced supplier of and have gained good reputaion among global customers. With a wide range of in offer, we can customize according to your requirement. Send us your enquiry at TENGDA Extruder Machine Manufacturers.

Do you want to find a provider to get your Application problem settled? If so, we suggest that you give a shot to Nanjing Tengda Machinery Co., Ltd.. Visit TENGDA Extruder Machine Manufacturers to learn more and contact us.

Application has a great positive reflects from our dear customers.