Understanding the Advantages of Plastic Sheet Extruders in Packaging Industry

Understanding the Advantages of Plastic Sheet Extruders in Packaging Industry

Introduction

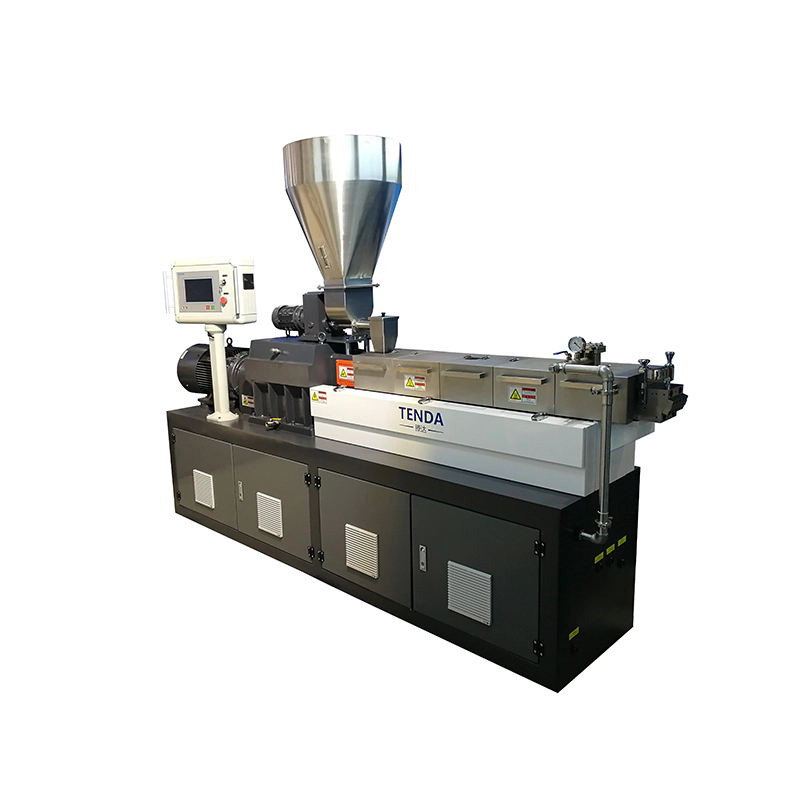

Plastic sheet extruders play a crucial role in the packaging industry, providing numerous benefits and advantages for manufacturers and consumers alike. These innovative machines have revolutionized the way packaging materials are produced, offering increased efficiency, versatility, and cost-effectiveness. This article delves into the many advantages of plastic sheet extruders, highlighting why they have become an integral part of the packaging industry.

Improved Production Efficiency

One of the primary advantages of plastic sheet extruders in the packaging industry is their ability to significantly improve production efficiency. These machines are capable of producing large volumes of plastic sheets in a relatively short amount of time. Unlike traditional methods, such as injection molding or blow molding, extrusion allows for continuous production, reducing downtime and increasing output. Manufacturers can produce sheets of various sizes and thicknesses, tailored to meet specific packaging requirements. This enhanced efficiency results in cost savings and allows companies to meet customer demands promptly.

Versatility in Applications

Plastic sheet extruders offer immense versatility in terms of applications in the packaging industry. These extruders can process a wide range of materials, including polyethylene (PE), polypropylene (PP), polymethyl methacrylate (PMMA), and polystyrene (PS), among others. This versatility allows manufacturers to produce plastic sheets suitable for various packaging needs, such as food packaging, medical packaging, consumer goods packaging, and more. Moreover, plastic sheet extruders can create sheets with different properties, including transparency, durability, and flexibility, making them adaptable to diverse product packaging requirements.

Cost-Effectiveness

Another key advantage of plastic sheet extruders is their cost-effectiveness. Compared to other manufacturing methods, extrusion offers significant cost savings in terms of raw materials, labor, and energy consumption. The continuous production process ensures maximum material utilization, minimizing waste. Additionally, plastic sheet extruders require less manual labor, as the process is largely automated, reducing production costs. Furthermore, these machines are increasingly energy-efficient, utilizing advanced technologies that optimize power consumption, resulting in long-term cost savings for manufacturers.

Enhanced Product Quality

Plastic sheet extruders are renowned for producing high-quality packaging materials. The extrusion process allows for precise control of the sheet thickness, resulting in consistent and uniform products. This uniformity ensures that the packaging materials meet stringent quality standards and provide optimal protection for the packaged goods. Plastic sheets produced by extruders also exhibit excellent clarity, making the packaged products visually appealing and enhancing brand visibility. The ability to incorporate additives, such as UV stabilizers or antimicrobial agents, further enhances the product quality, making plastic sheet extruders an ideal choice for packaging applications.

Customization and Innovation

The packaging industry thrives on innovation and customization, and plastic sheet extruders offer the flexibility to cater to these evolving demands. Manufacturers can easily modify the extrusion process to create unique products with specific features. For example, embossing patterns, logos, or color effects can be incorporated directly into the plastic sheet during the extrusion process, eliminating the need for secondary printing or labeling. This customization capability not only saves production time but also enhances the aesthetics of the packaging materials. Plastic sheet extruders empower manufacturers to bring their creative ideas to life and stay ahead in a highly competitive market.

Conclusion

Plastic sheet extruders have undoubtedly played an instrumental role in transforming the packaging industry. From improved production efficiency and versatility in applications to cost-effectiveness, enhanced product quality, and customization capabilities, these machines offer a wide array of advantages for manufacturers and consumers alike. Embracing plastic sheet extrusion technology enables packaging companies to produce innovative, high-quality, and cost-effective packaging materials, meeting the ever-changing demands of the market. As the future of the packaging industry continues to evolve, plastic sheet extruders will remain at the forefront, driving innovation and revolutionizing packaging production processes.