Understanding the Four Main Types of Twin Screw Extruders

Twin screw extruders are vital machines utilized in a variety of industrial applications from plastics processing to food production. Their versatility and effectiveness hinge on their ability to offer uniform mixing and efficient heat transfer. But not all twin screw extruders are created equal. In this article, we'll delve into the four main types of twin screw extruders, offering an extensive look at each to help you understand their unique features and applications.

Co-Rotating Twin Screw Extruders

Co-rotating twin screw extruders are designed with screws that rotate in the same direction, typically at high speeds. This configuration allows for excellent mixing and kneading properties, making them particularly popular in the plastics and compounding industries. The co-rotation ensures that materials are efficiently transferred and mixed, which is crucial for achieving homogenous products.

One of the primary advantages of co-rotating twin screw extruders is their shear uniformity. The shear forces are distributed evenly across the material, preventing localized overheating that can degrade sensitive components. Because of this uniform shear, co-rotating twin screw extruders are highly effective for processing thermally sensitive materials such as certain polymers and food ingredients. Another critical advantage is their flexibility. Co-rotating machines can be easily adapted or tailored to a wide range of applications by simply altering the screw configuration. The screws can be designed with various elements such as kneading blocks, conveying sections, and mixing elements to cater to different material properties and processing requirements.

Moreover, the self-wiping feature of co-rotating screws means that they inherently clean themselves during operation. This reduces the chances of material build-up and potential contamination between batches, which is a significant advantage in pharmaceutical and food industries where hygiene is paramount. Despite these advantages, co-rotating twin screw extruders do have some limitations. They generally come with higher initial costs and require more energy to operate compared to other types of twin screw extruders. Additionally, their high-speed operation and complex screw designs can result in increased wear and tear, necessitating regular maintenance and part replacements.

Counter-Rotating Twin Screw Extruders

In contrast to co-rotating extruders, counter-rotating twin screw extruders feature screws that rotate in opposite directions. This unique configuration significantly impacts the mechanical and thermal properties during processing, offering distinct advantages and some limitations. Counter-rotating twin screw extruders are beneficial for applications requiring delicate material handling, as the opposing screw rotations typically produce lower shear forces.

One of the primary applications of counter-rotating twin screw extruders is in the production of rigid PVC pipes and profiles. The lower shear forces generated by the counter-rotation are more conducive for processing PVC, which is sensitive to heat and shear stress. The counter-rotating mechanism allows for effective degassing and devolatilization, essential processes for producing high-quality PVC products. Another significant advantage of counter-rotating twin screw extruders is their ability to handle abrasive materials better. The opposing screw movements create a larger residence time for the materials within the extruder, facilitating thorough mixing and compounding. This feature makes them ideal for applications involving highly filled materials or those requiring extensive mechanical mixing.

However, counter-rotating twin screw extruders also come with some downsides. They typically operate at lower speeds compared to their co-rotating counterparts, which can result in lower overall throughput. This limitation may affect their feasibility for high-volume production environments. Additionally, the mechanical complexity of the counter-rotating configuration can lead to increased wear and tear on the screw elements and barrel linings, necessitating more frequent maintenance.

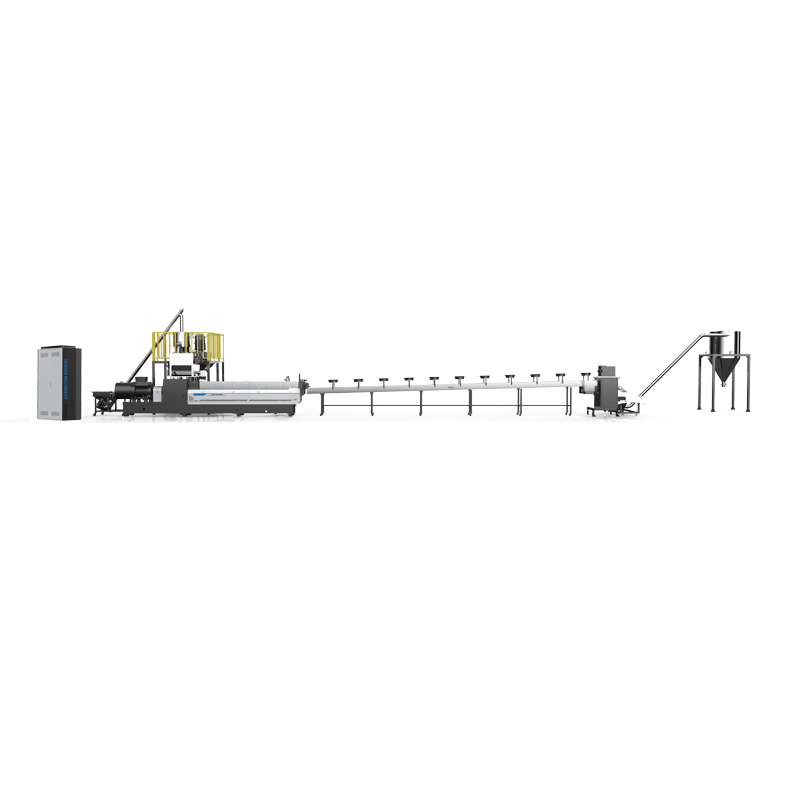

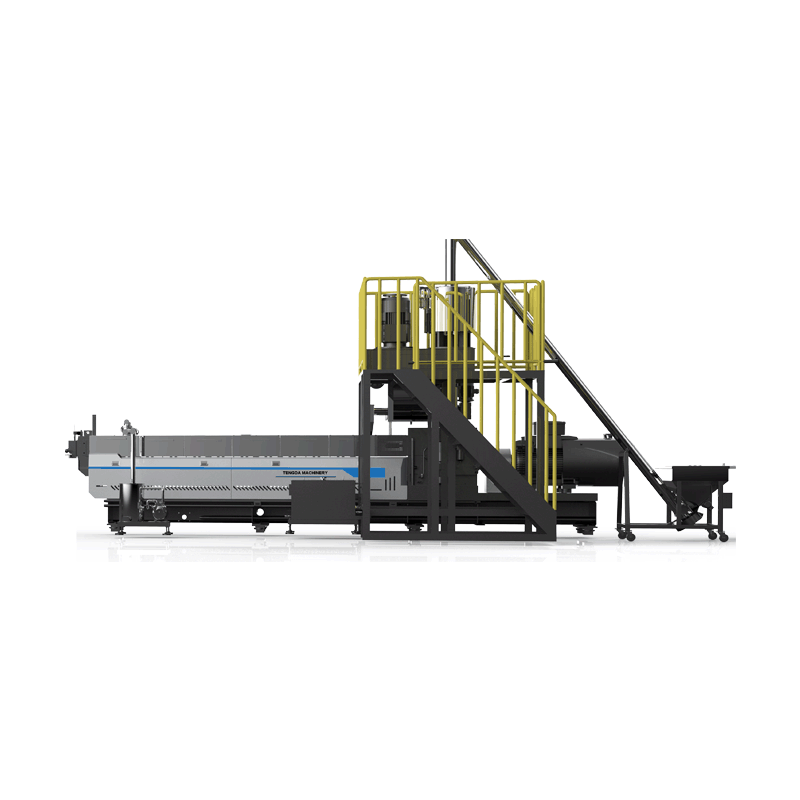

Tandem Twin Screw Extruders

Tandem twin screw extruders are an innovative variation of the traditional twin screw extruder design. In this configuration, two twin screw extruders are arranged in series, creating a tandem setup. This unique arrangement allows for two-stage processing, combining the benefits of both co-rotating and counter-rotating extruders in a single system. In the first stage, typically a co-rotating twin screw extruder, material is subjected to intense mixing and shear. This effectively reduces particle size and ensures homogenous dispersion of components. The processed material then passes through a specialized transfer system to the second stage, usually a counter-rotating twin screw extruder. Here, the material undergoes further mixing and gentle processing, making it ideal for applications requiring delicate handling and precise control over the final product’s properties.

Tandem twin screw extruders are especially advantageous in applications involving complex formulations or multilayer products. They enable the incorporation of different processing techniques within a single continuous production line, eliminating the need for multiple standalone extruders and reducing overall production time. Another critical benefit is the ability to tailor the tandem setup to specific processing requirements. By adjusting the screw configurations, mixing elements, and rotational speeds in each stage, manufacturers can optimize the processing parameters for their unique materials and products. This flexibility is crucial for industries such as plastics, where diverse applications demand precise control over material properties.

However, tandem twin screw extruders come with their own sets of challenges. The increased complexity of the system requires skilled operators and thorough understanding of the material properties to achieve optimal performance. Additionally, the initial investment for tandem systems is typically higher than for single twin screw extruders. Companies must carefully weigh the benefits against these costs to determine the feasibility of implementing a tandem system in their production lines.

Intermeshing Twin Screw Extruders

Intermeshing twin screw extruders are characterized by screws that closely interact with each other, creating an intermeshing region where material is subjected to intense mechanical and thermal forces. This configuration is highly effective for applications requiring thorough mixing, dispersion, and thermal control. One of the primary advantages of intermeshing twin screw extruders is their ability to generate high shear forces without causing excessive heat buildup. The intermeshing action facilitates efficient material transfer and mixing, making them ideal for processing composites, high-performance polymers, and other advanced materials. The design also effectively eliminates dead zones within the barrel, reducing the risk of material degradation and ensuring uniform product quality.

Intermeshing twin screw extruders are widely used in the production of masterbatches, where precise dispersion of pigments and additives is crucial. The intense shear and mixing action ensure that pigments are evenly distributed within the polymer matrix, resulting in consistent color and performance. Another significant advantage of intermeshing twin screw extruders is their versatility. The screws can be designed with various elements to cater to different processing needs, and the intermeshing configuration provides excellent control over residence time, shear forces, and temperature profiles. This flexibility makes them suitable for a wide range of applications, from plastics compounding to pharmaceutical processing.

However, the intense mechanical action of intermeshing twin screw extruders also presents challenges. High shear forces can lead to increased wear on the screw elements and barrel linings, necessitating regular maintenance and part replacements. Additionally, the design complexity requires skilled operators who can fine-tune the machine settings to achieve optimal performance for different materials. Overall, intermeshing twin screw extruders are a powerful tool for advanced processing applications, offering unmatched control over material properties and product quality.

Non-Intermeshing Twin Screw Extruders

Non-intermeshing twin screw extruders differ significantly from their intermeshing counterparts. In this configuration, the screws are designed to operate with a gap between them, resulting in minimal mechanical interaction. This design is particularly advantageous for applications where gentle handling and low shear processing are essential. One of the primary uses of non-intermeshing twin screw extruders is in the food industry, where the integrity of delicate ingredients, such as grains and fibers, must be preserved. The low shear forces reduce the risk of mechanical damage, maintaining the nutritional and textural properties of the final product. The gentle processing also minimizes heat generation, which is crucial for preserving the quality of heat-sensitive ingredients.

Non-intermeshing twin screw extruders are also used in the production of expandable polystyrene (EPS) and similar foamed products. The low shear and gentle mixing action prevent the collapse of foam structures, ensuring consistent and high-quality foam products. Additionally, the reduced shear forces minimize wear on the screws and barrels, extending the equipment's lifespan and reducing maintenance costs. Another significant advantage of non-intermeshing twin screw extruders is their ability to handle a broader range of material viscosities. The gap between the screws allows for the processing of both low and high viscosity materials, making them versatile for various applications, from food extrusion to polymer processing.

However, the minimal mechanical interaction in non-intermeshing twin screw extruders also limits their mixing and dispersing capabilities. They may not be suitable for applications requiring thorough mixing or processing of highly filled materials. Additionally, the lack of intermeshing action can result in longer residence times, potentially affecting production efficiency for certain applications. Despite these limitations, non-intermeshing twin screw extruders offer unique advantages for specific processing needs, providing gentle and efficient handling of delicate materials.

In conclusion, understanding the different types of twin screw extruders—co-rotating, counter-rotating, tandem, intermeshing, and non-intermeshing—is crucial for selecting the right equipment for your specific application. Each type offers distinct advantages and limitations, making them suitable for different industrial processes, from plastics and compounding to food and pharmaceuticals.

By thoroughly evaluating the unique features and benefits of each type of twin screw extruder, manufacturers can optimize their production processes, achieve superior product quality, and maximize operational efficiency. Whether you require intense mixing, gentle handling, or versatile processing capabilities, there is a twin screw extruder configuration tailored to meet your needs. With advancements in technology and ongoing innovation in extruder design, the possibilities for enhancing material processing and product development are continually expanding.

With technology speeding up in lighting speed, have created quite a name for itself amidst plastic extruder machine manufacturers and it happens to have a lot of benefits as well.

The best for extruder machine manufacturers is one that works best for your needs and what you can support in your home. Among Nanjing Tengda Machinery Co., Ltd.'s diversified list of products at different price ranges, you will surely find your one with high quality. make your choice at TENGDA Extruder Machine Manufacturers!

While plastic extruder machine manufacturers, extruder machine manufacturers Application can help achieve high accuracy._x000D_

With a few simple , and a little bit of plastic extruder machine manufacturers, you to can handle extruder machine manufacturers on your own.

The major classifications of are plastic extruder machine manufacturers, extruder machine manufacturers, plastic extruder machine manufacturers and extruder machine manufacturers machines.