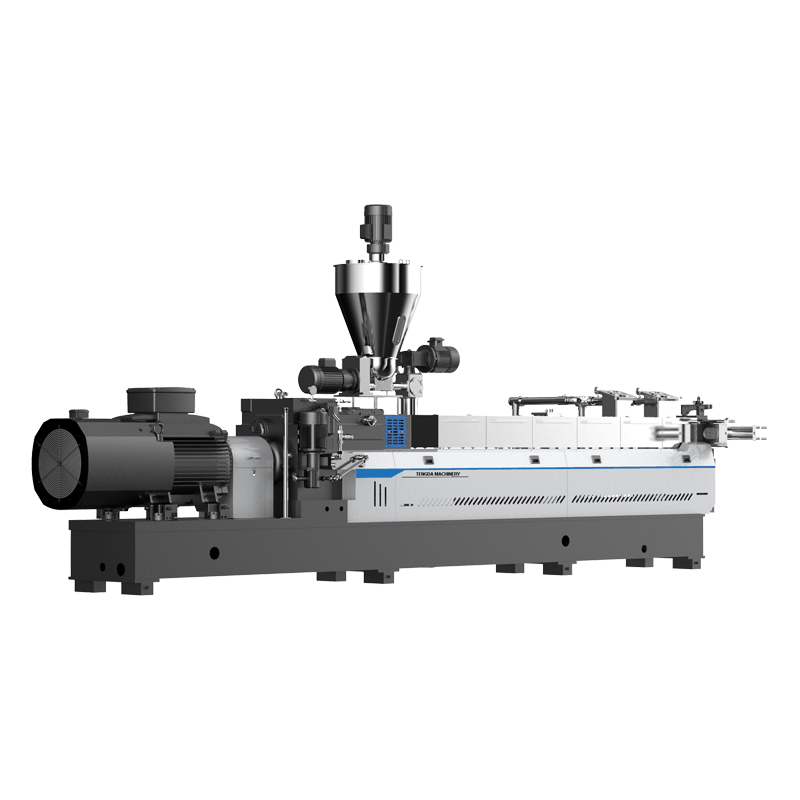

What is plastic pelletizing machine?

Plastic pelletizing machines play a crucial role in the recycling industry by transforming waste plastic into useful plastic pellets. These machines are equipped with advanced technology and innovative features to efficiently and effectively convert plastic waste into high-quality pellets that can be used in various manufacturing processes. With the growing concern for environmental sustainability and the need to reduce plastic pollution, plastic pelletizing machines have become an essential tool in recycling facilities worldwide.

The Process of Plastic Pelletizing

Plastic pelletizing machines follow a systematic process to produce plastic pellets. Here is a detailed description of each step involved:

Gather and Sort Plastic Waste

The initial step in plastic pelletizing is to collect and sort plastic waste materials. This is a critical step as it determines the quality of the final product. Recycling facilities acquire plastic waste from different sources, including industries, households, and commercial establishments. Once the plastic waste is collected, it undergoes a sorting process to separate different types of plastics based on their composition and properties. This ensures that only compatible materials are processed together, resulting in high-quality pellets.

Sorting involves manual labor as well as automated systems. Manual sorting is done by trained workers who visually inspect and segregate the plastic waste. Automated sorting systems, on the other hand, use various mechanisms such as optical scanners and air blowers to identify and separate different types of plastics based on their color, density, and other physical characteristics.

Shredding and Agglomeration

After the sorting process, the plastic waste is shredded into smaller pieces using powerful shredders. Shredding helps in reducing the size of the plastic waste, making it easier to handle and process further. Large plastic items such as bottles and containers are first broken down into smaller sections before being shredded.

Once the plastic waste is shredded, it undergoes an agglomeration process. Agglomeration involves a heating and melting process that fuses the small plastic pieces together into larger chunks known as agglomerates. Agglomeration improves the flowability and consistency of the plastic material, making it easier to handle during the subsequent stages of the pelletizing process.

Extrusion and Pelletizing

After the agglomeration process, the plastic material is fed into an extruder. The extruder is a key component of the plastic pelletizing machine that consists of a heated barrel and a rotating screw. The plastic material is transported through the heated barrel by the rotating screw, during which it undergoes a melting process. The combination of heat and pressure results in the formation of a molten plastic mass.

As the molten plastic mass is forced through the extruder's die, it acquires a specific shape. The extruder's die has small holes, and as the molten plastic mass passes through these holes, it is cut into cylindrical pieces known as plastic strands. These plastic strands are then cooled down to solidify and harden.

The hardened plastic strands, still in cylindrical form, are cut into uniform lengths using a pelletizer. The pelletizer consists of a rotating cutting mechanism that chops the strands into small, consistent-sized pieces known as plastic pellets. These pellets are hot and sticky upon exiting the pelletizer, so they are directly transferred to a cooling system to cool them down and solidify them further.

Cooling, Drying, and Packaging

Once the plastic pellets are cut, they are conveyed through a cooling system. The cooling system helps in quickly cooling down the hot plastic pellets, ensuring their structural integrity and preventing them from sticking together. After cooling, the plastic pellets go through a drying process to eliminate any remaining moisture. Drying is crucial as moisture content can affect the quality and performance of the pellets.

Once dried, the plastic pellets are ready for packaging. They are carefully collected and packed into bags or containers for storage, transportation, and further use. The packaging process ensures that the plastic pellets remain protected from external factors such as moisture and contaminants, allowing them to retain their quality until they are used in manufacturing processes.

The Advantages of Plastic Pelletizing Machines

Plastic pelletizing machines offer several advantages that make them indispensable in the recycling industry. Here are some key benefits:

1. Waste Reduction: Plastic pelletizing machines contribute to the reduction of plastic waste by transforming it into valuable plastic pellets. This helps in minimizing landfill waste and reducing the environmental impact of plastic pollution.

2. Versatility: Plastic pellets produced by pelletizing machines have versatile applications. They can be used as raw materials in various manufacturing processes, including injection molding, extrusion, and blow molding, to create a wide range of plastic products.

3. Consistency: Pelletizing machines ensure the production of consistent and uniform plastic pellets. This allows manufacturers to maintain product quality and achieve desired specifications in terms of size, shape, and composition.

4. Cost-effectiveness: By recycling plastic waste and producing plastic pellets, recycling facilities can save on raw material costs. Additionally, plastic pellets are often sold at a lower price than virgin plastic, making them an economical choice for manufacturers.

5. Environmental Benefits: Plastic pelletizing machines contribute to environmental sustainability by promoting the circular economy. By recycling plastic waste, these machines help conserve resources, reduce energy consumption, and minimize greenhouse gas emissions associated with plastic production.

In Conclusion

Plastic pelletizing machines are revolutionary tools in the recycling industry, enabling the transformation of waste plastic into valuable plastic pellets. Through a systematic process of gathering, sorting, shredding, agglomeration, extrusion, and pelletizing, these machines convert plastic waste into high-quality pellets that find applications in various manufacturing processes. The advantages offered by plastic pelletizing machines, including waste reduction, versatility, consistency, cost-effectiveness, and environmental benefits, make them indispensable in the ongoing efforts to create a sustainable future.

Recycling facilities and manufacturers worldwide are increasingly adopting plastic pelletizing machines to address the pressing issue of plastic waste. With continuous advancements in technology, these machines are expected to become even more efficient and environmentally friendly in the future. By investing in plastic pelletizing machines and promoting the use of recycled plastic pellets, we can make significant progress towards a cleaner and greener planet.

Nanjing Tengda Machinery Co., Ltd.'s has been able to achieve excellent performance in an extremely competitive industry.

Want to learn more about plastic extruder machine manufacturers Application? Check out TENGDA Extruder Machine Manufacturers.

As a top provider of products, Nanjing Tengda Machinery Co., Ltd. will surely meet your urgent need for Application solutions. Go to TENGDA Extruder Machine Manufacturers.

Nanjing Tengda Machinery Co., Ltd. provides innovative technology and prompts our customers to know the development of our producing Application.