Acceptance requirements for internal mixer (3)

Three: load test run

1. After the no-load trial operation of the mixer is qualified, the load trial operation can be carried out. During the load trial operation, each equipment shall be operated with a continuous load of no less than 20 vehicles;

2. During the load trial operation of the mixer, the rotation speed should be carried out from low speed to high speed respectively, and the soft material should be tested first and then the hard material;

3. During the load trial operation of the mixer, the amount of glue added will gradually increase from 50% to 75% of the working volume to the full load;

4. The internal mixer should have an interlocking device that starts the lubricating oil pump before starting the main motor. At the same time, it can run dry for 10-15 minutes before feeding the material for load trial operation; masterbatch granulator

5. After the end of the last car of rubber mixing, it will be stopped after idling for 15-20 minutes; during idling, the end face sealing lubrication system will continue to inject oil into the sealing surface to clean and lubricate the sealing end face;

6. The following items should be checked during the load trial operation of the mixer:

(1) Whether the basic technical parameters meet the requirements of the internal mixer.

(2) The temperature rise of the rotor bearing should be ≤40℃.

(3) The temperature rise of the reducer bearing should be ≤40℃.

(4) The maximum temperature of rotor and reducer bearing Z is ≤80℃.

(5) The oil temperature in the hydraulic system oil tank is ≤60℃.

(6) The maximum temperature of the fixed ring of the rotor end face sealing device is ≤85℃.

(7) The glue removal temperature (measured) should be consistent with the temperature value of the sensor display (thermocouple), and the difference is 3-5 °C.

7. There is no leakage of glue or powder at the end face seal of the rotor of the mixer, allowing glue, oil and powder mixture to leak out;

8. The discharge door should be well sealed without leakage;

9. The electrical and hydraulic control systems of the mixer should be flexible, safe and reliable;

10. The temperature control effect of the internal mixer temperature control system can meet the requirements of the rubber mixing process, and the discharge temperature should be within the allowable range of the process conditions;

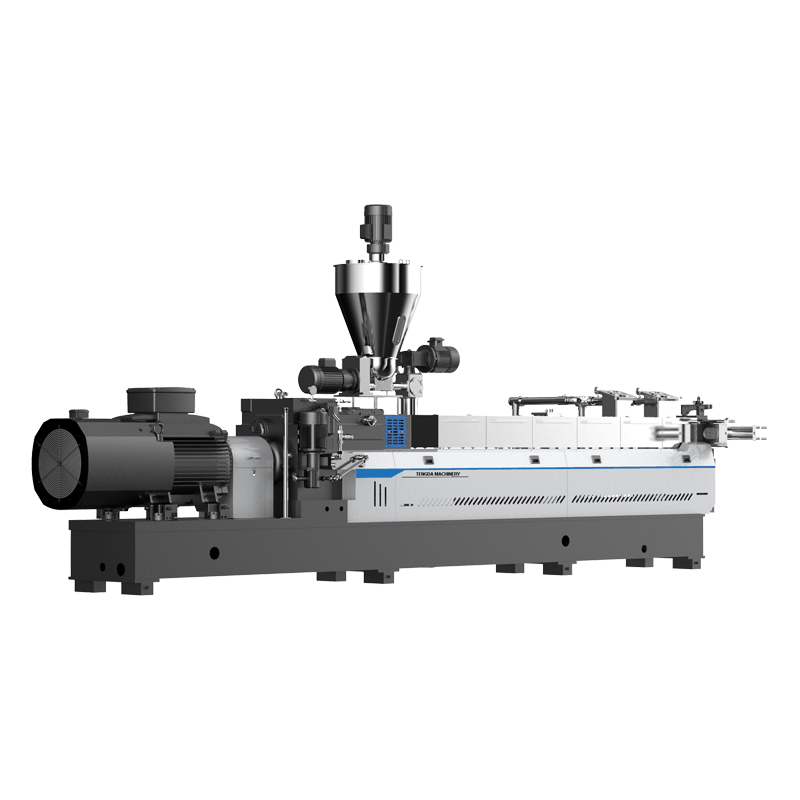

Currently there is a global trend growing. People are more conscious about extruder machine manufacturers and are seeking alternatives to traditional solutions.

So, get ready to dazzle the world with a wide range of plastic extruder machine manufacturers Application! Buy one today!! Visit Nanjing Tengda Machinery Co., Ltd. at TENGDA Extruder Machine Manufacturers.

The major classifications of are extruder machine manufacturers, plastic extruder machine manufacturers, extruder machine manufacturers and plastic extruder machine manufacturers machines.

Nanjing Tengda Machinery Co., Ltd. are providing this to you at very low cost. Our claims are only based on different feed-backs received from various clients and not based on self-judgment.

Advanced technology and manufacturing equipment has enhanced the core quality of Application.