Advantages of twin screw extruders

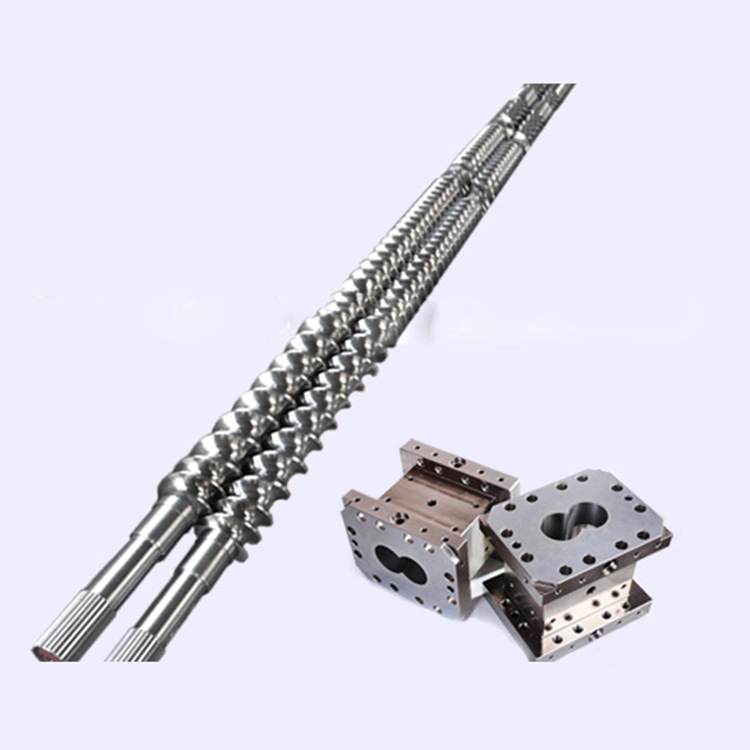

The operation mode of the twin-screw extruder is very simple and can be easily opened, so you can find out the wear degree of the inner barrel and the threaded components in time, so as to carry out effective maintenance or replacement, which can greatly reduce unnecessary of waste. The scope of use of twin-screw extruders has become quite extensive, and it is often used to process materials. In addition, the number of twin-screw extruder manufacturers that produce this equipment has also increased, in order to meet people's various needs.

We all know that it is extremely common to change the color when manufacturing masterbatches, while the traditional extruder needs to use a large amount of cleaning material for cleaning when changing the color, which is time-consuming and power-consuming, and wastes raw materials. On the contrary, the twin-screw extruder can solve this problem. When changing the color, the barrel can be quickly opened in a few minutes for manual cleaning, so that no or less cleaning material can be used, which saves costs.

The screw extruder is actually a high-tech product equipment. It is mainly composed of two parts: the main machine and the auxiliary machine. It is the main machine itself, and the auxiliary machine mainly includes pay-off, preheating and straightening devices. A part is quite critical, and they play a great role, so everyone must ensure that the structure of their twin-screw extruder is complete.

TENGDA saves time and increases productivity because it's one of the most complete sources of business and contact information.

If you are interested in , click TENGDA Extruder Machine Manufacturers to see some items with features that you will be amazed at.

We are making Application available to you at a very low price.

Nanjing Tengda Machinery Co., Ltd. deems that we can drive consumer transactions using high-tech tools like artificial intelligence and cognitive data sets.