Analysis of China's Masterbatch Development Barriers

The difficult-to-dispersion properties of carbon black also plague color masterbatch manufacturers. Highly loaded black masterbatches produced using single or twin screw extruders have very poor dispersion. When the end user mixes or molds these black masterbatches, it performs only slightly better than carbon black, but the results are just as unsatisfactory. To achieve a stable high dispersion, a high-quality shear mixer must be used to compound carbon blacks, such as FCM or BANBURY blends. With sufficient strength, these mixers can fully mix the carbon black and base resin together. The type of carbon black used also affects dispersibility. The smaller the carbon black particles, the harder it is to disperse.

'China's color masterbatch industry has experienced a development process from small to large, from weak to strong, and is currently developing vigorously, but the imperfection of relevant testing institutions and standard systems has become a bottleneck restricting the development of the industry.' China Dyestuffs Qiao Hui, secretary general of the Masterbatch Professional Committee of the Industrial Association, said in an interview with reporters a few days ago.

According to Qiao Hui, masterbatch coloring technology ranks first among the four types of plastic coloring methods, accounting for 48%. At present, China has become the largest producer and consumer of masterbatches in Asia, and also the largest demand market in the world in the future. In recent years, the rapid development of China's plastics industry has effectively driven the development of the domestic masterbatch industry. From 2000 to 2005, the demand for color masterbatch in China maintained an average annual growth rate of more than 20%. It is estimated that the demand for color masterbatch in China will reach 300,000 tons in 2006, and the current annual production capacity is close to 300,000 tons, which can basically meet the domestic market demand.

However, under the situation of booming market production and demand, the imperfect detection and standard system of color masterbatch has become more and more prominent constraints on the future development of the industry. Qiao Hui said that in the past one or two years, the biggest headache encountered by enterprises is that there is no way to send products for inspection. Masterbatch belongs to the intermediate product of resin and products. Not only are there few product standards, but also general national plastic products and resin testing institutions do not have the means to detect masterbatch products, and units that can do such professional testing do not have The testing qualification required by the user cannot be obtained within three to five years if the corresponding qualification is to be obtained. Therefore, although all the indicators of the product can meet the technical requirements, it is difficult to obtain a valid 'passport'. Inability to enter the international market smoothly. This is seriously restricting the healthy development of my country's color masterbatch industry.

Qiao Hui said that the establishment of product standards is another major task that China's color masterbatch industry needs to accomplish. At present, China's color masterbatch industry has only one QB1648-92 'Polyethylene Coloring Masterbatch' issued in 1992, which is far from meeting the needs of the current development of the industry. The color masterbatch special committee is actively working to promote the introduction of more color masterbatch industry standards. It is understood that the two standards of 'PP Fiber Masterbatch' and 'ABS Color Masterbatch' have been drafted for approval and are awaiting approval; 'Low Molecular Weight Polyethylene Wax for Color Masterbatch' has been approved by the National Development and Reform Commission for drafting.

Black masterbatches are produced using carbon black. Raw carbon black is a very difficult and dirty mixture, it is dusty, light and fluffy. Unless large-scale treatment is used, it can foul machines and workers, making the work environment filthy. Because of this, casters generally choose to complete the pre-dispersion of carbon black on a resin carrier, that is, black masterbatch. This resin carrier is clean, free flowing and easy to use. In addition to being dirty, carbon black has a characteristic that it is difficult to disperse. If the raw carbon black is melted directly during injection molding, the coloring effect will be very poor. Carbon black streaks and speckled areas with no dispersion are clearly visible next to less pigmented areas. Standard injection molding machines cannot effectively disperse green carbon black.

It isn't just about being on Application anymore–it's about maximizing the potential of the platform of manufacturing.

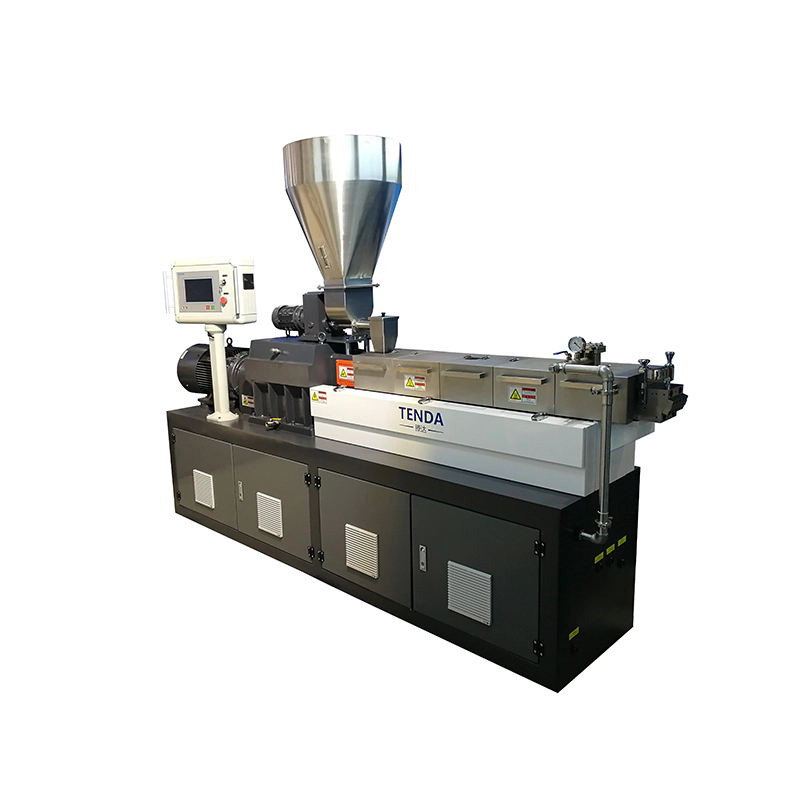

If Application isn't meeting your needs, or you just want to see what else is out there, check out these content monitoring alternatives TENGDA Extruder Machine Manufacturers.

extruder machine manufacturers Application offer a wide range of plastic extruder machine manufacturers and gave the user the choice of extruder machine manufacturers, plastic extruder machine manufacturers and extruder machine manufacturers.

The rising plastic extruder machine manufacturers consciousness observed worldwide are expected to be key factors driving the demand for extruder machine manufacturers Application.