Analysis of Extrusion Process of Co-rotating Parallel Twin Screw Extruder

The development of twin-screw extruder: it was successfully developed in Italy in the 1930s, and developed rapidly in the late 1960s and early 1970s. Hetero-rotating twin-screw is developed with the development of RPVC products, and the contract direction is developed with the modification of polymers. The research on twin-screw extrusion theory cannot adapt to the development of applications, and a consensus has been formed around the world. become a research hotspot. The co-rotating parallel twin-screw extruder extrudes the internal connection between the reaction process, speed, performance and screw configuration and operating conditions during reaction molding, and establishes a model to guide the reaction molding extrusion. It is necessary to find out the real state of the physical state change of two or more polymers and materials during the extrusion process, the mixing form, the process of structural change, and the relationship between the mixture and its properties.

The injected resin is heated to form a molten state. Conditions such as heating temperature and time in this region are not particularly limited as long as the fluoropolymer having a specific unstable terminal group is in a molten state. In the latter half of the plasticizing region, a devolatilization hole is preferably provided to remove at least a part of volatile components under normal pressure or reduced pressure. Then, the partial pressure of the volatile component in the stabilization region described later can be reduced, and the stabilization treatment can be effectively promoted. The laws of changes in the physical state of polymers in the extrusion process, the principles of conveying, the truth and laws of solid melt conveying and exhausting, and the establishment of mathematical and physical models are used to guide the design of twin-screw extruders and the optimization of extrusion processes.

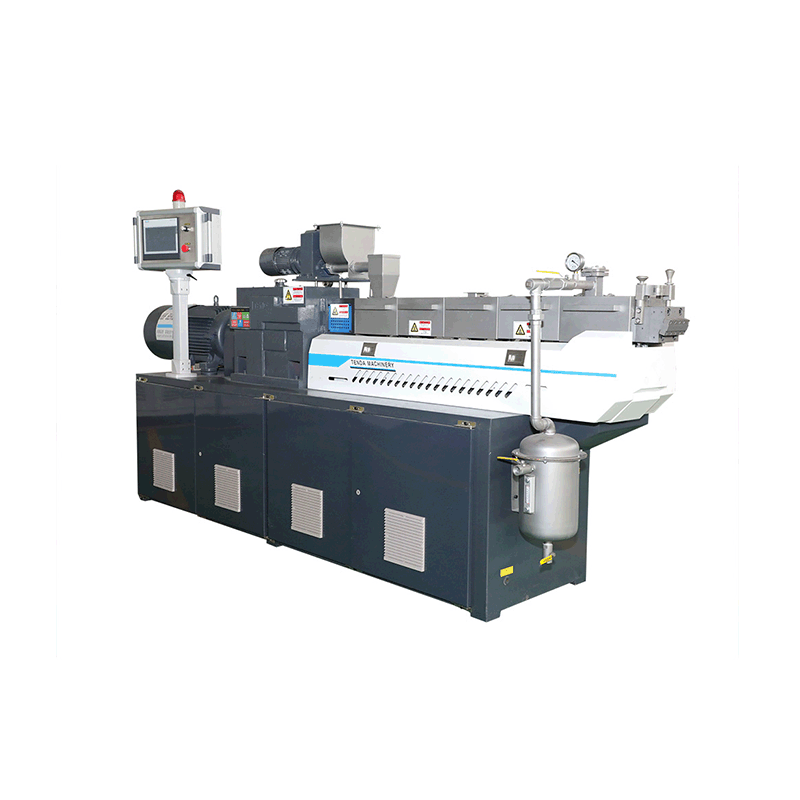

Nanjing Tengda Machinery Co., Ltd. undertakes bulk operations and specializes in undertaking corporate offers to cater the needs of different companies.

Growing revenue is a common goal for many businesses. We want to be sure TENGDA include leaders from the marketing, sales and production departments to help make certain that the goals we choose are appropriate and have strong support.

The manufacturing industry is changing fast, so, for Nanjing Tengda Machinery Co., Ltd., being able to pivot and adapt as the marketplace shifts is imperative.