Analysis of the Causes of Working Noise of Plastic Extruder

Normally speaking, the test noise of the plastic extruder does not exceed 85db (A). This noise standard is a major indicator of the manufacturing quality of the extruder, and it is a comprehensive reflection of the manufacturing quality and assembly accuracy of the extruder parts. When this noise value is too high, the first step is to find out.

1. The reason for the rotation and friction sound of the screw in the barrel

1. The concentricity error of screw and barrel assembly is large.

2. There is a large error in the perpendicularity between the end face of the machine barrel and the end face of the connecting flange of the machine base and the center line of the machine barrel.

3. The screw rod is bent and deformed, and the straightness of the axis line is out of tolerance.

4. The assembly gap between the screw of the extruder and its supporting drive shaft is too large, and the misalignment error is large when rotating.

Second, the reason why the motor of the plastic extruder rotates loudly

1. The rotor bearing is relatively large and low.

2. The straightness error of the axis line of the rotor shaft is large.

3. The reason why the belt drive of the plastic extruder produces a lot of noise;

1. The assembly gap between the inner hole of the pulley and the transmission shaft is relatively large.

2. The manufacturing precision of the pulley is low, and the runout of the end face and the outer circle is relatively large.

3. The installation positions of the two transmission pulleys, the end faces are not on the same plane, and the error is large.

Fourth, the cause of the high noise of gear transmission

1. The gear manufacturing precision is not high, and the gear tooth torque error is large.

2. The error value of the center line of the transmission shaft of the gear is relatively large. When the center distance is small, gear transmission meshing interference noise is generated.

3. The precision of the supporting rolling bearing of the shaft is low.

4. The parallelism of the centerlines of the two transmission shafts is out of tolerance, so that the gears cannot be properly meshed for transmission.

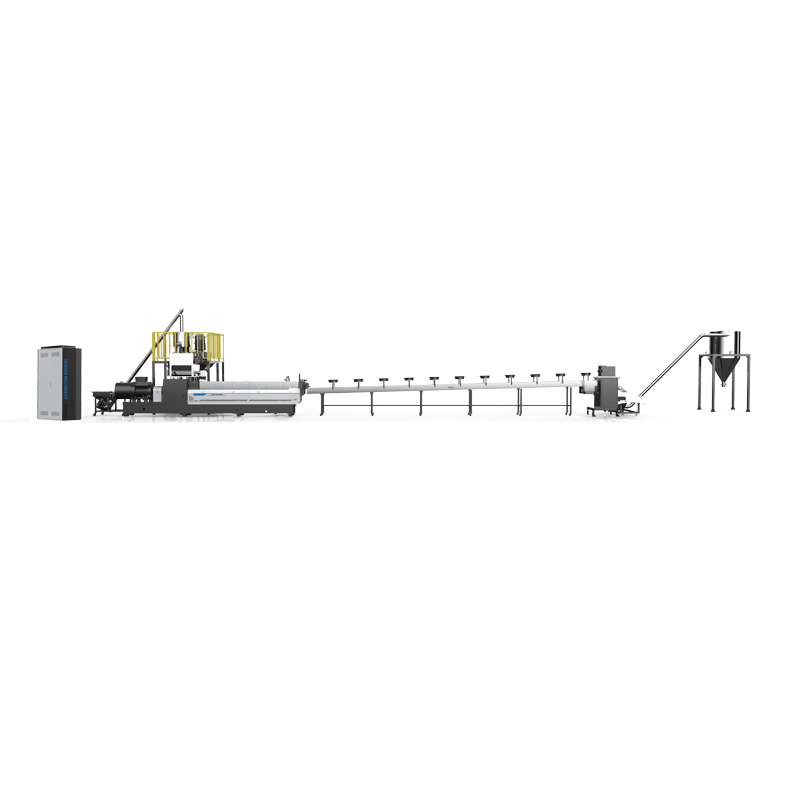

The use of extruder machine manufacturers Application is a great trend in today's world. What you should know is that it has become a very important part of business today.

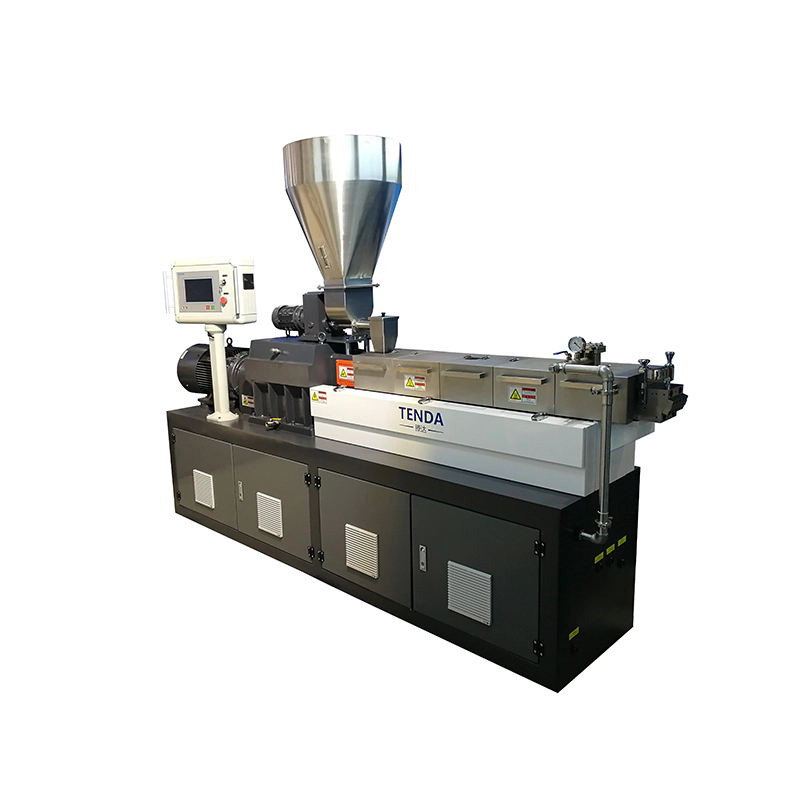

Looking for someone to handle your Application plastic extruder machine manufacturers needs? Check out TENGDA Extruder Machine Manufacturers today for more information.

The trend toward using extruder machine manufacturers Application to ease plastic extruder machine manufacturers, once established, soon extended into such additional fields as extruder machine manufacturers and plastic extruder machine manufacturers.

People tend to want what they perceive they cannot have. Making TENGDA seems exclusive or as if it will go out of stock if they don't act quickly often makes it more enticing to the consumer and increases the likelihood that they will buy in.