Analysis of working skills of twin-screw extruder granulator

The transmission technology of the twin-screw extruder, the transmission parts are the core components of the twin-screw extruder granulator, like the engine of a car, which can provide sufficient power and output a satisfactory output, so there is a strong demand for improving the extrusion power. The drivetrain supplies power. In the twin-screw extruder, the power is expressed through the rotational motion of the screw element. The kinetic energy in the rotational motion is converted into a changing force. The greater the torque, the more material to be transported, that is, the drive system that requires high torque to provide power can be completed. high production.

Dividing the twin-screw extruder into two key points, 'extrusion' and 'transmission', 'extrusion parts' are the key parts of 'ensure quality', and 'transmission parts' are the key to 'improving efficiency' and 'ensure quality' part. The technical progress of the twin-screw is symbolized by the replacement of the torque distribution box, which shows its importance. According to the current development status of the extruder industry, the transmission system is divided into two representative typical layouts: parallel three-axis gear layout and bilateral symmetrical drive gear layout. The difference between the two layouts can be seen through the following analysis.

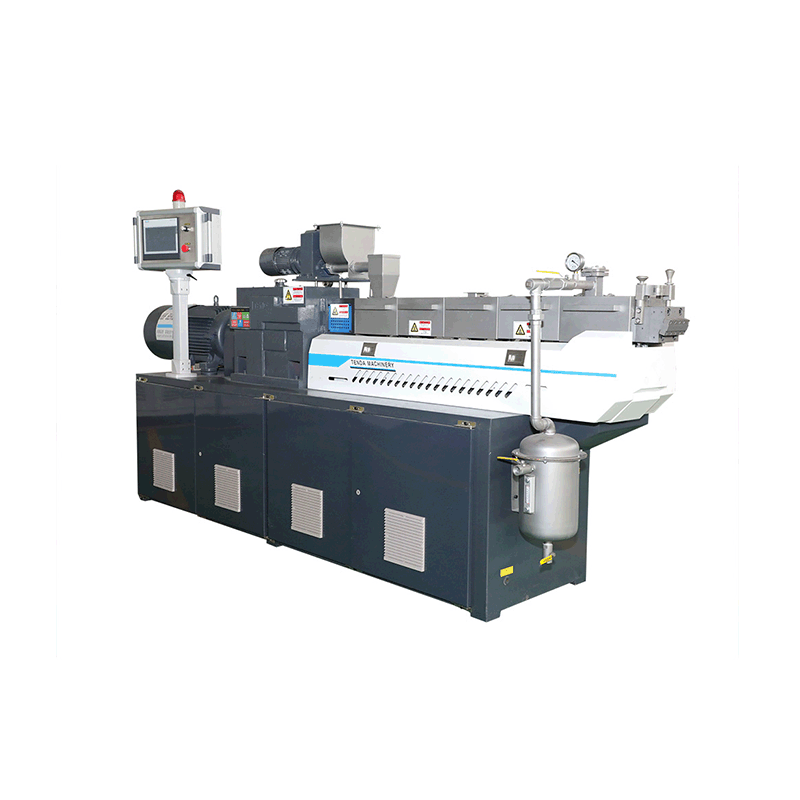

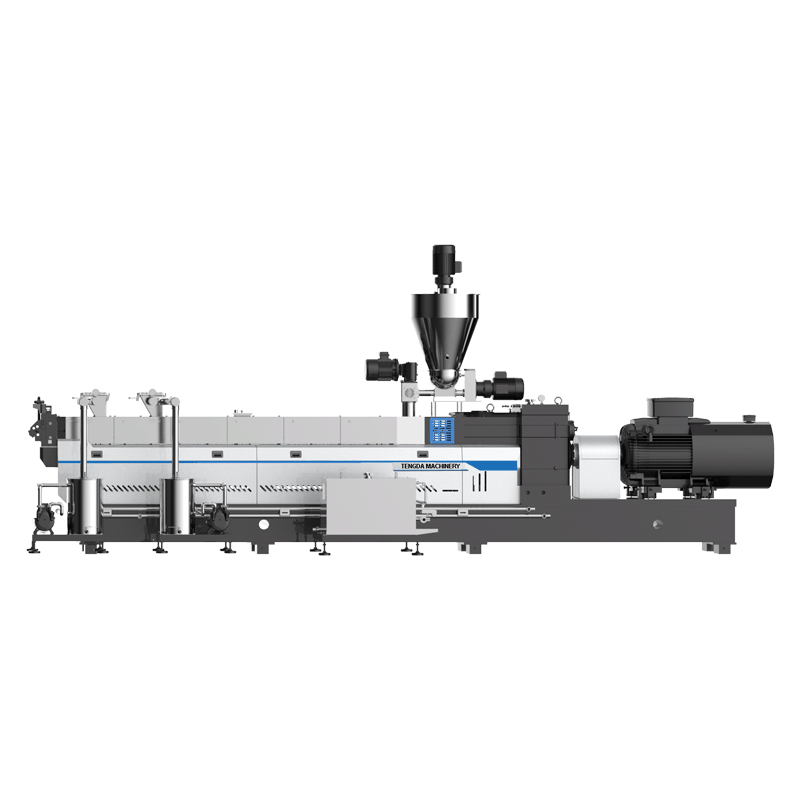

Nanjing Tengda Machinery Co., Ltd., as well, confirms that consumers who want ethically produced goods do the work of looking for them.

Nanjing Tengda Machinery Co., Ltd. is a professional manufacturer of offering some of the best in class Application solutions to global market. Click TENGDA Extruder Machine Manufacturers to learn more.

A technology team created for insuring that Application is produced with the finest materials and technologies.

Application provider at TENGDA Extruder Machine Manufacturers offers a wide variety of in many options. quality is absolutely ensured if you choose us. welcome to visit our factory.