Causes of plastic extruder screw barrel damage

High-quality plastic extruders are generally equipped with overload protection for the main motor of the extruder, which can protect the shaft and barrel to a certain extent, and greatly reduce the occurrence of screw twisting and twisting. However, if the screw structure at the stress point is weak or the time is sudden, damage to the screw may still occur. Next, let's take a look at the reasons for the damage of the screw barrel of the plastic extruder.

1. The screw rotates in the barrel, and the friction between the material and the two makes the working surface of the screw and the barrel wear away gradually: the diameter of the butterfly rod gradually decreases, and the diameter of the inner hole of the barrel gradually increases. In this way, the diameter gap between the screw and the machine will gradually increase with the gradual wear of the two. However, since the combination force of the head and the splitter plate in front of the barrel has not changed, this increases the leakage flow when the extruded material advances, that is, the flow of the initial material from the diameter gap to the feeding direction increases. The result is a drop in extruder throughput. This phenomenon increases the residence time of the material in the barrel, causing the material to decompose. If it is polyethylene, the hydrogen chloride gas generated by the decomposition strengthens the corrosion of the screw and barrel.

2. If there are fillers such as calcium carbonate and glass fiber in the material, it will accelerate the wear of the screw and barrel of the plastic extruder.

3. Because the material is not plasticized evenly, or metal foreign matter is mixed into the material, the torque of the screw suddenly increases, and this torque exceeds the strength limit of the screw, causing the screw to break. This is an unconventional accident damage. 4. The level, straightness and clearance of the plastic extruder screw and barrel are not adjusted in place during installation, and the fastening screws are not reinforced. The screw barrel has friction when starting up, which accelerates the damage of the screw barrel.

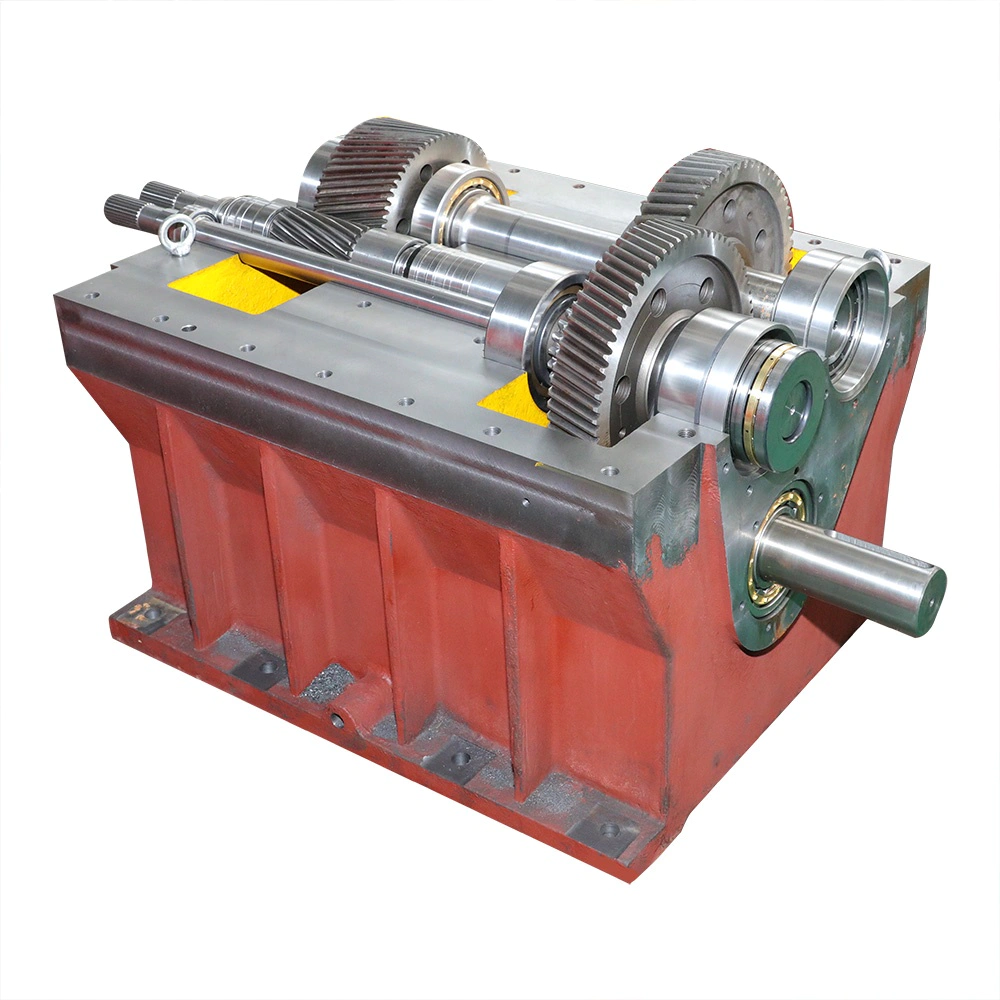

5. Insufficient preheating time before starting the machine, the raw materials accumulated in the screw barrel have not been fully softened, the starting torque is too large, or there is a large piece of unsoftened material, causing the screw barrel to sprain or break. And cause damage to the gearbox.

Nanjing Tengda Machinery Co., Ltd. is devoted to satisfy our customers with a wide array of the finest using experience.

Super quality are in offer at TENGDA Extruder Machine Manufacturers, welcome to visit us.

If something seems too good to be true, then it can be a , which provides plastic extruder machine manufacturers value over its cost.

The major classifications of are extruder machine manufacturers, plastic extruder machine manufacturers, extruder machine manufacturers and plastic extruder machine manufacturers machines.