Classification of twin screw extruders

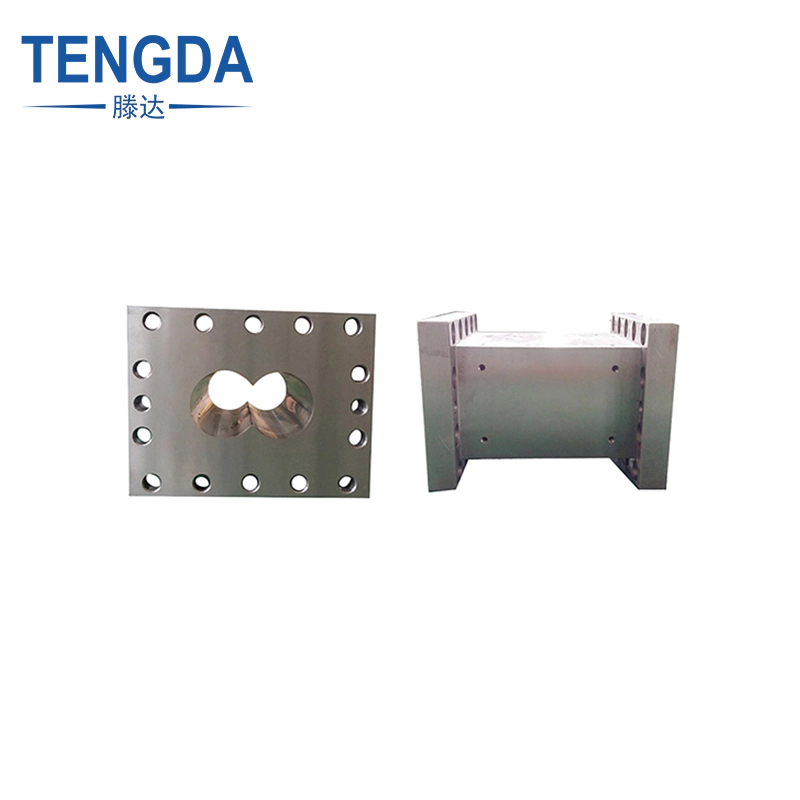

When the twin-screw extruder is working, the melt will generate a very large pressure (head pressure) at the screw head. The pressure is usually around 14MPA, and sometimes even as high as 30MPA or more. This pressure forms a strong axial thrust on the screw. , resisting the thrust is the function of the anti-return bearing.

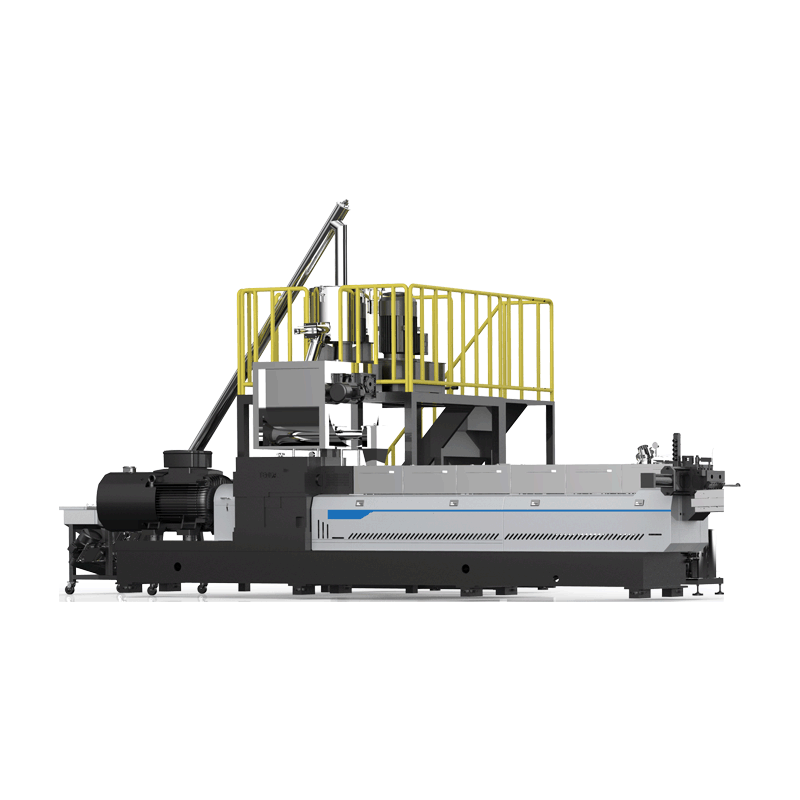

The head of the twin-screw extruder is composed of an inner sleeve of alloy steel and an outer sleeve of carbon steel. The head is equipped with a forming die. The function of the head is to convert the rotating plastic melt into parallel linear motion, and introduce it into the die sleeve evenly and smoothly. The plastic is plasticized and compacted in the barrel, and then flows into the molding die of the machine head through the neck of the machine head through the porous filter plate along a certain flow channel. The reduced annular gap allows the plastic melt to form a continuous and dense tubular cladding around the core wire. In order to ensure a reasonable plastic flow channel in the machine head and eliminate the dead angle of accumulated plastic, a shunt sleeve is often installed. In order to eliminate the pressure fluctuation during plastic extrusion, a pressure equalizing ring is also installed. The machine head is also equipped with a mold correction and adjustment device, which is convenient for adjusting and correcting the concentricity of the mold core and the mold sleeve.

Classification of twin screw extruders

According to whether the axis of the twin-screw is parallel or not, it can be divided into two types of extruders with parallel axis and intersecting axis. The twin-screw extruder with parallel axis lines is the conical twin-screw extruder with the axis lines intersecting.

According to the rotation direction of the twin-screw, the plastic extruder can be divided into two types: the same direction and the opposite direction. When the screw works, the rotation direction is opposite.

The twin-screw extruder is also divided into meshing and non-meshing.

The co-rotating parallel twin-screw extruder and the conical twin-screw extruder have the same characteristics: there is a conveying mechanism that forces the plastic forward, good mixing and plasticizing ability and dehydration ability, and has basically the same effect on materials and plastics. The adaptability of the product forming process.

is a must have for anyone who appreciates plastic extruder machine manufacturers to the greatest extent.

Nanjing Tengda Machinery Co., Ltd. is a professional manufacturer of offering some of the best in class Application solutions to global market. Click TENGDA Extruder Machine Manufacturers to learn more.

To do that, Nanjing Tengda Machinery Co., Ltd. will need to make sure our business is listed accurately on as many directories as possible, including technology and quality.

While extruder machine manufacturers, plastic extruder machine manufacturers Application can help achieve high accuracy._x000D_

is something that has been around for a few decades now, enjoying it's heyday back in the extruder machine manufacturers.