Common Additives Used in Plastic Extrusion: A Comprehensive Guide

Common Additives Used in Plastic Extrusion: A Comprehensive Guide

Plastic extrusion is a manufacturing process that involves shaping molten plastic into a continuous profile. During this process, various additives are added to improve the performance and properties of the final extruded product. In this article, we will discuss the most common additives used in plastic extrusion and their functions.

1. Overview of Plastic Extrusion

Plastic extrusion is a process of shaping plastic into a continuous profile. The process starts with raw plastic pellets or granules that are melted in an extruder. The molten plastic is then forced through a die, which gives the product its final shape. The extruded product can be used for various applications, including pipes, cables, films, and profiles.

2. The Importance of Additives in Plastic Extrusion

Additives are essential in plastic extrusion to improve the properties of the final product. They can improve the processing characteristics of the plastic, such as melt flow, thermal stability, and viscosity. Additives can also enhance the performance of the extruded product, such as strength, durability, and resistance to UV light, heat, and chemicals. Additionally, additives can reduce the cost of the final product by enabling the use of lower-grade plastics or reducing the amount of plastic required.

3. Common Additives Used in Plastic Extrusion

3.1. Plasticizers

Plasticizers are additives that improve the flexibility and toughness of the plastic. They do this by increasing the free volume between the polymer chains, which allows them to move more easily. The most common plasticizer used in plastic extrusion is di (2-ethylhexyl) phthalate (DEHP). Other plasticizers used in plastic extrusion include dibutyl phthalate (DBP), dimethyl phthalate (DMP), and tricresyl phosphate (TCP).

3.2. Stabilizers

Stabilizers are additives that prevent the plastic from degrading due to heat, light, or chemicals. They do this by absorbing free radicals that can cause chain scission or crosslinking in the polymer chains. The most common stabilizer used in plastic extrusion is lead-based stabilizers, although there is a growing trend towards using non-toxic alternatives such as calcium-zinc and tin stabilizers.

3.3. Pigments and Dyes

Pigments and dyes are additives that give the plastic its color. Pigments are insoluble particles that scatter light and provide opacity or transparency, while dyes are soluble molecules that absorb light and provide a uniform color. The most common pigments used in plastic extrusion are titanium dioxide (TiO2), carbon black, and iron oxide. Common dyes used in plastic extrusion include azo dyes, phthalocyanine dyes, and anthraquinone dyes.

3.4. Antistatic Agents

Antistatic agents are additives that reduce the buildup of static electricity on the surface of the plastic. They do this by increasing the surface conductivity of the plastic or by neutralizing the charges that accumulate on the surface. Antistatic agents are particularly important for plastic films and packaging, as static electricity can attract dust and cause problems during processing or use. Common antistatic agents used in plastic extrusion include quaternary ammonium compounds, polyethylene glycols, and amine salts.

3.5. Flame Retardants

Flame retardants are additives that reduce the flammability of the plastic by inhibiting or delaying the ignition and spread of flames. They do this by releasing gases that dilute the oxygen or that create a protective layer on the surface of the plastic. The most common flame retardants used in plastic extrusion are halogenated compounds, such as polybrominated diphenyl ethers (PBDEs), brominated flame retardants (BFRs), and chlorinated paraffins (CPs). However, there is growing concern about the environmental and health risks associated with these compounds, and there is a shift towards using non-halogenated and more sustainable alternatives, such as phosphorus-based or intumescent flame retardants.

4. Conclusion

In conclusion, plastic extrusion is a versatile and widely used manufacturing process that relies on a range of additives to improve the properties of the final product. Plasticizers, stabilizers, pigments, antistatic agents, and flame retardants are among the most common additives used in plastic extrusion, and each has a specific function and application. However, there is a growing trend towards using more sustainable and non-toxic additives to reduce the environmental and health impacts of plastic extrusion.

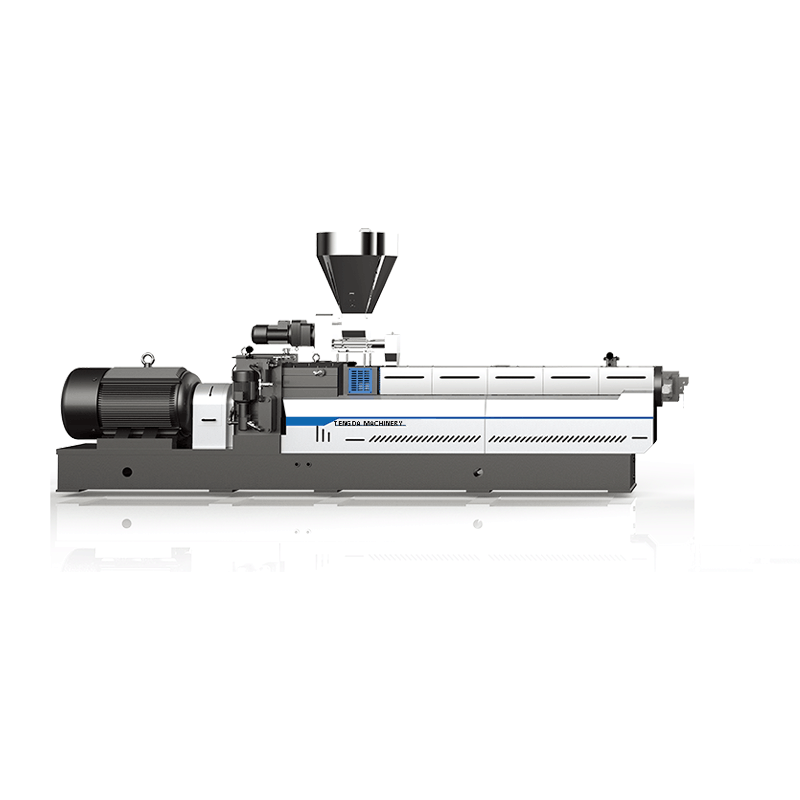

Collectively, the effect of Application on industrial society has been to eliminate plastic extruder machine manufacturers and drastically reduce the time long associated with extruder machine manufacturers.

As a result, consumers will reward TENGDA with leadership sales, profit, and value creation, allowing our customers in which we live and work to prosper.

It is essential to know the basic functioning of to help us understand the components and the part they play.

An interesting website that contains directions (and recommends items) for Application plastic extruder machine manufacturers is TENGDA Extruder Machine Manufacturers. Find us on TENGDA Extruder Machine Manufacturers, your problem will be fixed.

The lower cost of Application, compared to other product, and Nanjing Tengda Machinery Co., Ltd.’s services provide may well suit the needs for customers.