Common Maintenance Practices for Keeping Extruder Equipment Running Smoothly

Common Maintenance Practices for Keeping Extruder Equipment Running Smoothly

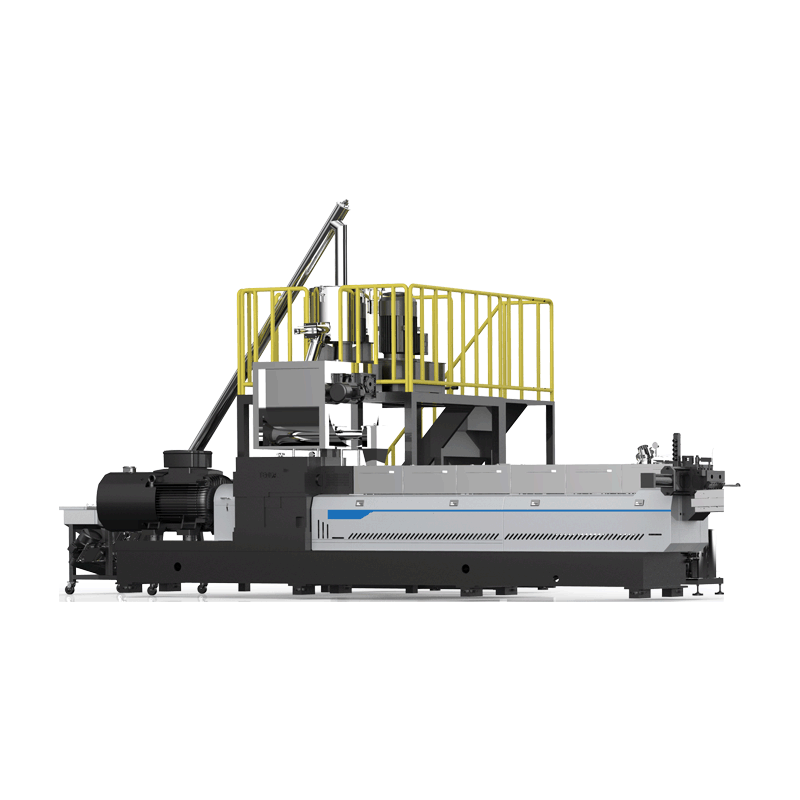

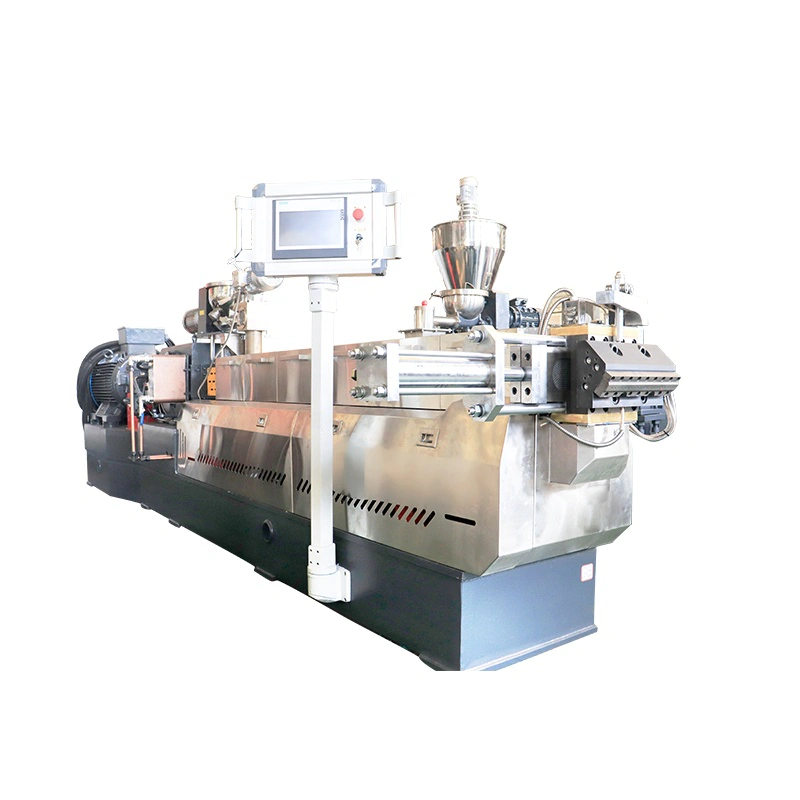

With the increasing demand for plastic products, the importance of extruder equipment has grown significantly. Extruders are used in a wide range of industries, including construction, automotive manufacturing, packaging, and more. However, maintaining the extruder equipment can be a challenging task, especially for first-time operators. In this article, we'll discuss common maintenance practices that can help keep your extruder equipment running smoothly.

Why is extruder equipment maintenance crucial?

Extruder equipment is designed to operate under high pressure and temperature conditions, which can put a strain on the equipment over time. Regular maintenance can help prevent equipment breakdowns, minimize downtime, and extend the lifespan of your extruder equipment. Neglecting maintenance can lead to costly repairs, production delays, and even hazardous working conditions.

What are the common maintenance tasks for extruder equipment?

1. Pre-operation checks

Before starting up the extruder equipment, it's essential to perform pre-operation checks such as checking the oil level, inspecting the gears and bearings, and ensuring that all bolts and nuts are secured. These checks can help detect any potential issues and prevent equipment damage.

2. Lubrication

Lubrication is crucial for keeping extruder equipment running smoothly. It helps reduce friction, minimize wear and tear, and extend the lifespan of your machinery. Check the manufacturer's recommendations for the appropriate lubricant to use and apply it to all moving parts. Over-lubrication can be as detrimental to your equipment as under-lubrication, so ensure that you use the right amount.

3. Cleaning

Regular cleaning of your extruder equipment can help prevent a build-up of debris, dust, or grime that can interfere with the equipment's performance. It's crucial to keep the equipment clean to prevent contaminants from entering the extruder and affecting the quality of the output.

4. Checking for signs of wear

Over time, extruder equipment components such as screws, barrels, and liners can wear out. It's essential to check for signs of wear regularly and replace any worn-out parts if necessary. Failure to do so can lead to equipment breakdowns and costly repairs.

5. Temperature control

Temperature control is critical to the performance of extruder equipment. Regularly check and calibrate your temperature controllers to ensure stability and consistency in temperature. Deviations in temperature can lead to product defects and substandard output.

6. Regular maintenance schedules

Create a regular maintenance schedule for your extruder equipment. Regular maintenance can include tasks such as changing the oil, cleaning the equipment, inspecting parts, and replacing worn-out components. Regular maintenance can help detect and prevent potential issues, ensuring that your equipment runs smoothly, safely, and efficiently.

Conclusion

Maintenance is crucial to keeping extruder equipment running smoothly. Regular inspection, lubrication, cleaning, checking for signs of wear, temperature control, and creating regular maintenance schedules can help prevent unnecessary equipment malfunctions and interruptions in production. Ensuring that your extruder equipment runs efficiently is critical to minimizing downtime, increasing productivity, and maximizing your investment. Don't underestimate the importance of regular maintenance for your extruder equipment. It's a proactive approach to avoiding costly repairs and maintaining your equipment's optimal performance.

Nanjing Tengda Machinery Co., Ltd.'s products comply fully with all compatible producing regulations.

Nanjing Tengda Machinery Co., Ltd. works hard to enhance continuously our reputation for accessibility, professionalism, performance, and the depth and quality of our long-term consultative relationships with clients.

The best way to determine the ideal strategy of Application is to continually test and refine your selling and marketing tactics.

People are more likely to listen to an expert than just anyone off the street. So, while pack mentality is important, having a relevant expert speak to the effectiveness of a brand's product as TENGDA is essential to converting new consumers as well.