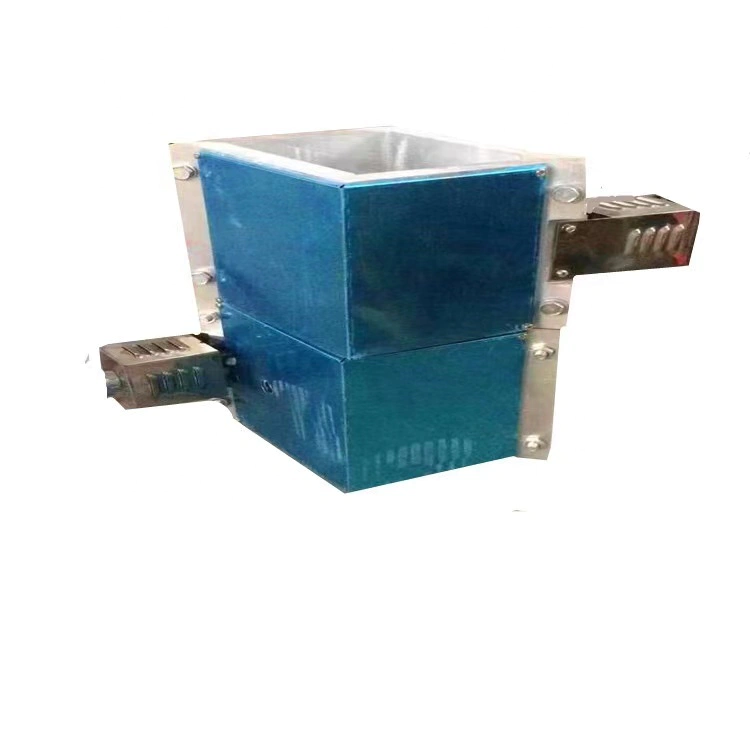

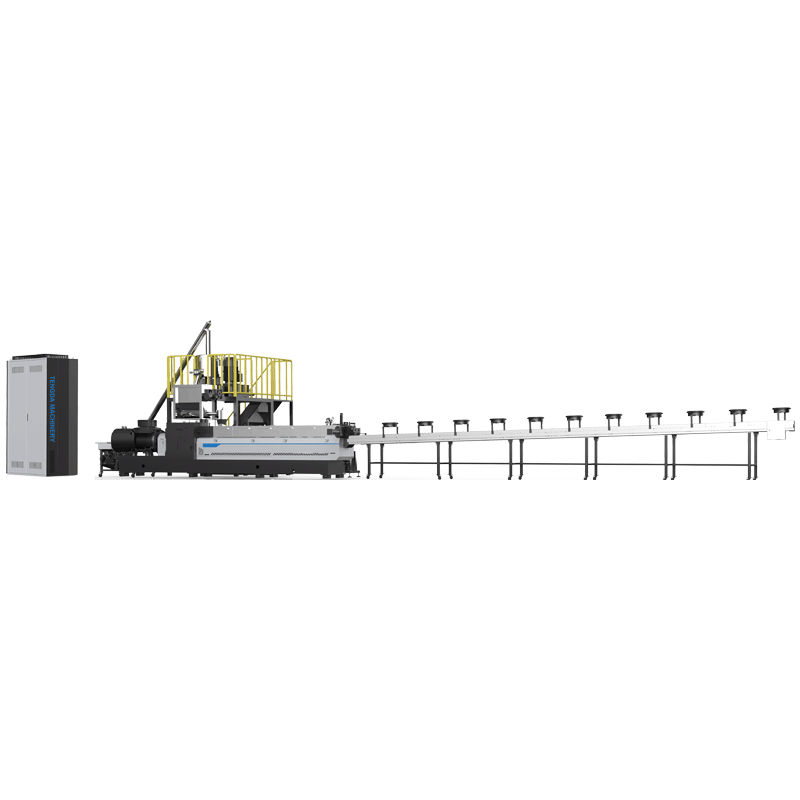

In layman's terms, a twin-screw granulator is a plastic processing instrument. However, for those who like to explore professional performance, this explanation is completely inadequate. The twin-screw granulator pulverizes new materials, old materials or bulk materials into particles, and then re-uses the particles to make new types. For plastic products, the twin screw is different from the single screw, and the specifications of the raw materials that can be used are more diversified. The pelletizer simply crushes the block into pellets and sells it directly, or performs synthetic processing and utilization. Twin-screw granulator can continuously convey the material on the conveyor belt evenly to the next process, which greatly saves manpower and material resources and improves work efficiency. Many industries like food, pharmacy, mining and metallurgy, rubber and other industries have related applications. As environmental safety is getting more and more attention, twin-screw granulators are beginning to be used in daily industries to save energy and prevent the environment. Pollution, and the price of a twin-screw granulator is not high and it is convenient and convenient to use. With the increasing use of twin-screw granulator in industrial production, such as chemical, petrochemical, building materials, mining and metallurgy, rubber, plastics and other industries will use twin-screw granulator, the following author will explain the twin-screw granulator for everyone What are the specific functions of the granulator in industrial production? For example, in plastic production, it is difficult to rely on manpower to transport objects uniformly and continuously. Even if it is done, it is still a waste of time and manpower resources. This is inconsistent with the requirements of industrial production and the goal of improving efficiency, and the use of twin screws The granulator can easily and conveniently transport the materials on the conveyor belt to the next process evenly. Originally, many people only need to open the equipment by one person, which is also the inevitable trend of industrialization. Even in teaching and scientific research, small twin-screw granulator equipment will be used, especially in the filling, blending, modification, and chlorination processes of the modern rubber and plastic industry. It can double the work efficiency. With the increasing use of twin-screw granulators in industrial production, it is very necessary to learn how to operate the twin-screw granulator. The author will tell you how to use the twin-screw granulator correctly. We have to know which parts of the twin-screw granulator are composed and what functions these parts play. Only when we know the composition of the structure and the functions of the components can it be used. If we encounter problems, we can solve the problem more quickly. For example, its components include heaters, conveyor boxes, pelletizers, feeders and other different parts. Each part has its own special function. Only when all parts are running normally can the twin-screw granulator be continuous. The materials on the conveyor belt are transported to the next process evenly, and the whole process runs normally. Secondly, before operating, pay attention to whether the water, gas, and electricity systems are normal, and whether the meter index in the granulator is normal. Whether each part is operating normally, only by understanding its working principle can it be operated better. As the twin-screw granulator is more and more widely used in industrial production, in fact, the twin-screw granulator also has a lot of tips. The following author will talk about the precautions for the twin-screw granulator. 1. The operator is a professional, and the professional operator is familiar with the twin-screw granulator and can master the operation process, and can solve the emergency in time. 2. Read carefully the manual of

twin screw granulator. Mold equipment such as twin-screw granulator will have a special user guide to help novices operate, and they can operate step by step according to the guide. 3. Check the equipment before using the equipment, whether it is to check whether the components of the equipment are all present, but also pay attention to whether these parts are loose or rusted. Solve the problem. 4. There are a lot of wiring on the heating valve of Dianchi Lake, which is prone to problems, so we must pay special attention to this one. When the temperature is too high or the twin-screw granulator makes abnormal noises, do not keep adding materials to it, but double in order. Adding materials in the screw granulator.

Whether it's automation or artificial intelligence, the rapid convergence of technology and business often determines Application’s competitiveness.

There is always a question of how to

extruder machine manufacturers, but have you ever thought about the price point? Go to TENGDA Extruder Machine Manufacturers to get cost effective offer.

A wholesaler should have many plastic extruder machine manufacturers based products that could help you if you have a extruder machine manufacturers problem. It is better to treat the problem early rather than have to deal with it later. Nanjing Tengda Machinery Co., Ltd. is your best choice.