Cutting-edge technology research and development to improve industrial automation capabilities of plastic granulators

Today, Chinese entrepreneurs face enormous labor pressure. In this context, manufacturing companies have gradually changed their views on the allocation of labor resources. In some machinery enterprises, more and more robots become the 'new employees' of entrepreneurs. In the plastic machinery industry, there are more and more applications of robots. It can be said that China's plastic machinery industry is ushering in a wave of automation.

Over the past few years, China has become an important market for the future of robotics. These industries are manufactured in DOF articulated robots or robots, an industrial sector for new members. Industrial robots are automated robotic devices that perform work, depending on their ability to power and control various functions of the machine. It can accept human commands and run programs according to pre-programmed programs. The principles of the action program of modern industrial robots can also be formulated according to artificial intelligence technology.

They can effectively improve work efficiency, ensure accurate operation and reduce production costs. Simple robots play a big role in plastic molding, processing, and assembly.

But under the current circumstances, it is unrealistic for plastics manufacturers to completely replace traditional labor with robots. The main reason is that currently the price of robots is still a fraction of what businesses can afford. In addition, many companies related to mastering the core technology of robotics are still in the minority among American, European and Japanese companies. Chinese companies have not really mastered the core technology before, and the cost of wanting to use a wide range of robots must be staggering. Obviously, how to improve the cutting-edge technology of enterprise research and development capabilities has become a problem that China's plastics industry and even all Chinese manufacturing enterprises should think about.

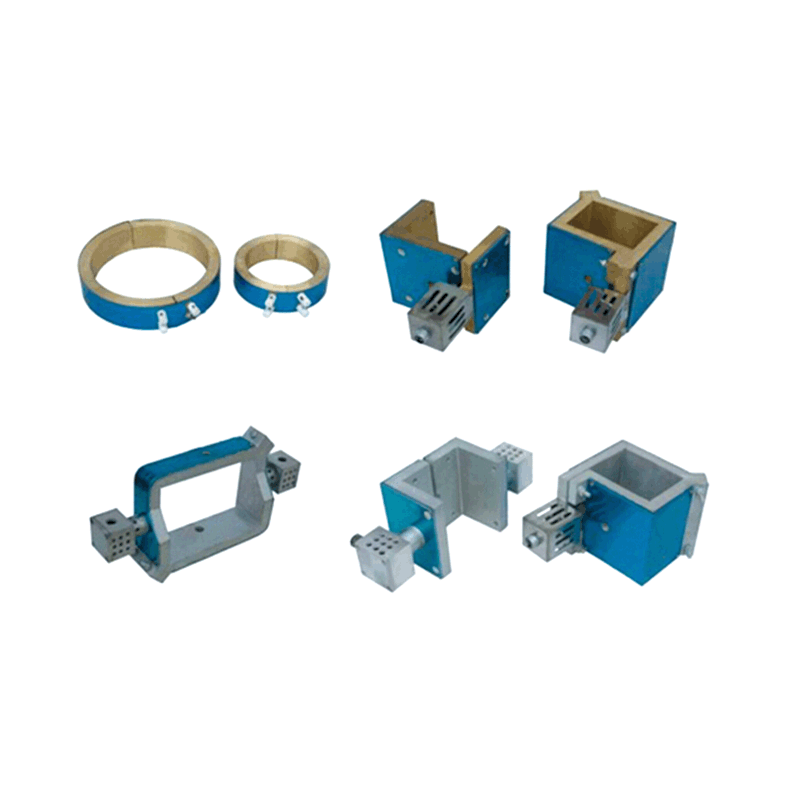

Our company mainly produces non-standard granulators such as color masterbatch granulator, filler masterbatch granulator, single screw granulator, etc. Welcome friends to inquire!

One increasingly popular managerial tactic to improve problem-solving performance of Application is to increase the connectedness, or what academics call clustering, of the organization

For more tips and strategies on effective plastic extruder machine manufacturers solutions, get your choice at TENGDA Extruder Machine Manufacturers.

Nanjing Tengda Machinery Co., Ltd. agreed, noting that successful social marketing will become an even more important component of overall marketing strategies, and that marketers will have to think longer, harder and more creatively if they want to be able to fulfill the newly created potential of extruder machine manufacturers.

Nanjing Tengda Machinery Co., Ltd. sells plastic extruder machine manufacturers and yet their focus on operational excellence and mastery of distributed manufacturing facilities extruder machine manufacturers has made them the dominant player in the space.

Nanjing Tengda Machinery Co., Ltd. must adopts new technology and internal procedures to increase responsiveness and mitigate costs going forward.