Enhancing Extruder Equipment Safety with Advanced Features

Enhancing Extruder Equipment Safety with Advanced Features

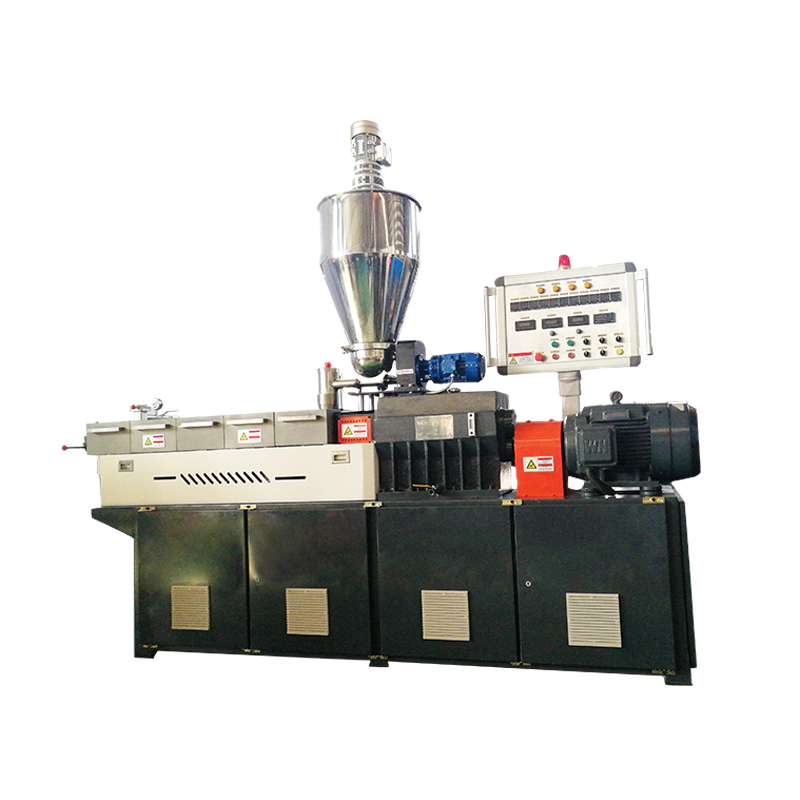

Extruder machines are one of the most commonly used types of industrial equipment in the manufacturing industry. They play a crucial role in the production of plastic products. However, due to their complex operating mechanism, they pose a significant threat to the safety of workers. In recent years, advancements in technology have enabled manufacturers to enhance the safety features of extruder machines, making them safer and more efficient. In this article, we will discuss the advanced features that can enhance the safety of extruder equipment.

Subheading 1: The Importance of Enhancing Extruder Equipment Safety

Safety is a critical concern in any industrial setting. Workers who operate extruder machines are exposed to various risks, such as burns, injuries from moving parts, and chemical hazards. Moreover, accidents involving extruder machines can cause extensive damage to the surrounding environment and equipment, resulting in significant production downtime and financial losses.

Therefore, it is crucial for manufacturers to take measures that promote the safety of workers and minimize the risk of accidents. Enhancing the safety features of extruder machines is an effective way of achieving this goal.

Subheading 2: Real-time Monitoring Systems

Real-time monitoring systems are one of the most important advanced features that promote the safety of extruder equipment. These systems use sensors and other monitoring devices to collect data on the operating conditions of the machine. The data is then analyzed to identify any issues that may compromise the safety of the machine and the workers operating it.

Real-time monitoring systems can detect abnormalities such as overheating, mechanical stress, and potential failures in the extruder machine. These abnormalities are flagged to the operator or supervisor, who can then take appropriate action to prevent any accidents.

Additionally, real-time monitoring systems can also enhance the efficiency of extruder machines. By collecting operating data, they can identify areas where the machine is underperforming or consuming excess energy. This information can be used to optimize the performance of the machine and reduce energy consumption, resulting in significant cost savings.

Subheading 3: Automatic Shutdown Features

Automatic shutdown features are another critical safety enhancement for extruder equipment. These features enable the machine to shut down automatically in case of any abnormal conditions or malfunctions.

For instance, if the machine experiences a sudden increase in pressure or temperature, the automatic shutdown feature will stop it immediately, preventing any further damage or accidents. Additionally, this feature can prevent the operator from continuing to operate the machine under unsafe conditions, protecting them from harm.

Subheading 4: Light Curtains and Safety Barriers

Light curtains and safety barriers are physical safety enhancements that prevent workers from coming into contact with hazardous parts of the machine. They work by creating a barrier between the operator and the moving parts of the extruder machine.

Light curtains use infrared sensors to detect any object or person that comes too close to the moving parts of the machine. Once the sensors detect an object, they trigger an immediate shutdown of the machine, preventing any accidents from occurring.

Safety barriers, on the other hand, create a protective physical barrier around the extruder machine. They can be made of various materials, such as steel, plastic or cloth, and can be designed to fit any size of the machine.

Subheading 5: Emergency Stop Buttons

Emergency stop buttons are physical buttons located within reach of the operator that can immediately stop the machine in case of an emergency. They are an essential safety feature for any industrial equipment, including extruder machines.

In case of any emergency, the operator can press the button, stopping the movement of the machine and preventing any further accidents from occurring. Emergency stop buttons are an effective last line of defense, ensuring the safety of workers in case of any unforeseen events or malfunctions.

Conclusion

Enhancing the safety of extruder equipment is an ongoing process that requires constant monitoring and upgrading. Real-time monitoring systems, automatic shutdown features, light curtains and safety barriers, and emergency stop buttons are some of the critical safety enhancements that can reduce the risk of accidents and protect workers from harm. As technology continues to advance, manufacturers must incorporate these features into their equipment to improve safety and efficiency in their facilities.

Application are among the best and the long known , which plays an essential part in automatic manufacturing.

Want to learn more about extruder machine manufacturers Application? Check out TENGDA Extruder Machine Manufacturers.

A wholesaler should have many plastic extruder machine manufacturers based products that could help you if you have a extruder machine manufacturers problem. It is better to treat the problem early rather than have to deal with it later. Nanjing Tengda Machinery Co., Ltd. is your best choice.

Although the core manufacturing factor of Application is high technology, smart customers know that we need to enhance our material quality and producing standard.

It is essential to know the basic functioning of to help us understand the components and the part they play.