Environmentally friendly, high-efficiency and energy-saving color masterbatch granulator

High-efficiency, energy-saving and environmentally friendly granulation technology configuration: high-dispersion production process, the mixer adopts a single-screw granulator structure, the environmental protection, energy-saving and high-efficiency polymer dispersion effect is excellent, the main machine current is small, energy saving and consumption reduction. Services and Environmental Protection. The calcium carbonate filler masterbatch is mainly made of PP/PE as raw materials, and the calcium carbonate filler and filling amount reach more than 80%.

The material is completely plasticized by the mixer and dispersed into the elevator. After passing through the conical double feeder, the material is forced into single-screw core water and all dispersed.

According to the characteristics of the calcium carbonate filler masterbatch, a major improvement has been made. The former uses a hydraulic mixer for mixing, and the sealing adopts hydraulic sealing, which can solve the problem of powder leakage in the previous mixer and greatly improve the surfing effect. ACE modification of calcium carbonate to improve the dispersion effect of calcium carbonate filler masterbatch.

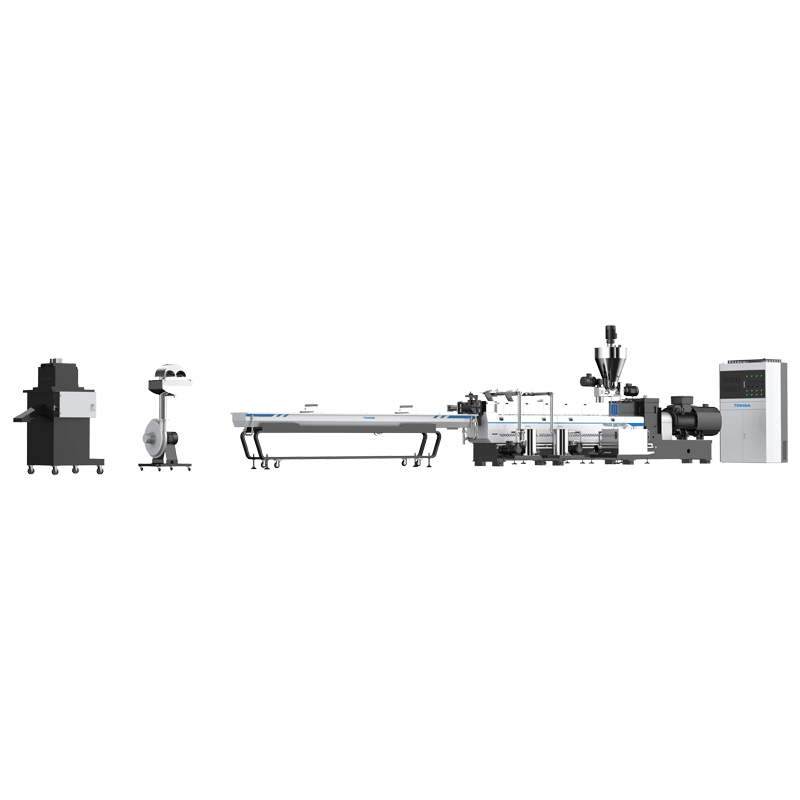

Energy-saving, environmentally friendly and efficient granulator structure: 1. Mixer, 2, 3. Cone-lifting double feeder (specially used for feeding the mixer block) 4. Single-screw granulator (full material compaction and extrusion) ) 5. Blowing head (cut into particles) 56. Secondary cyclone separator (for cooling and scattering) 7. Expanded air-cooled vibrating screen (filter) 8. Finished product warehouse.

There are three main production processes.

1. Polyethylene cement formula: calcium carbonate is the main component. However, it is also necessary to add some supporting materials such as (you must add an appropriate amount of lubricant, coupling agent, accelerator) and auxiliary materials such as granulation to meet the requirements of production and use.

2. Granulation: The current market mainstream is as follows: 1. Blender (with good ingredients to disperse) - 2. Elevator (add the material refined by the mixer to the feeder) (3) double-cone forced feeding (refine the dough with a mixer, and force-feed the single-screw extruder with a conical double-feeder) single-screw main machine (material Compression squeeze) - 5. Air-cooled quench head (single screw extruder is expected to pelletize) 6. Cyclone Separator (Bulky Material Particle Cooling) 7. Shaker (carefully sieve and large particles) - 8. Bin (complete)

3. Key technical requirements: better mixing and granulation of raw materials, so that the next stage of the papermaking process will not produce bubbles, breaks, gaps, voids and other phenomena.

These Application plastic extruder machine manufacturers are meant to serve as a guide for business owners on how to both identify potential opportunities for transformative innovation and how to adapt to the constantly changing technologies of today.

If you would like to solve your extruder machine manufacturers problem by adopting a . Nanjing Tengda Machinery Co., Ltd., an experienced and professional peovider having won high reputation globally will be your bast choice. You won't be disappointed

What Nanjing Tengda Machinery Co., Ltd. discovered was that innovation occurs when business models match up with one or more of the Application where technological advances overlap with market needs, thus resulting in growth and transformation.

It is one of the best products available in the market today. Application is famous product in many oversees market.